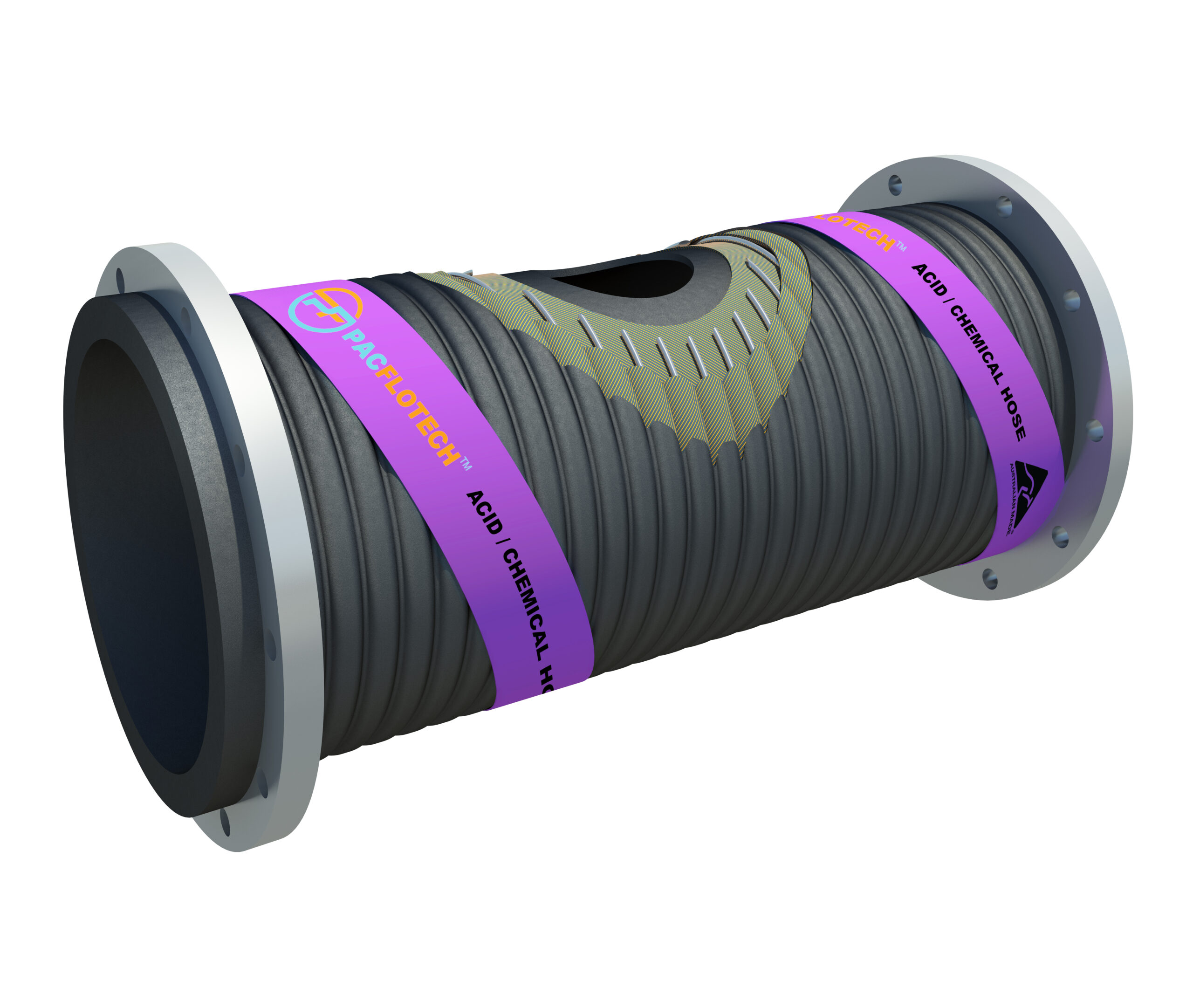

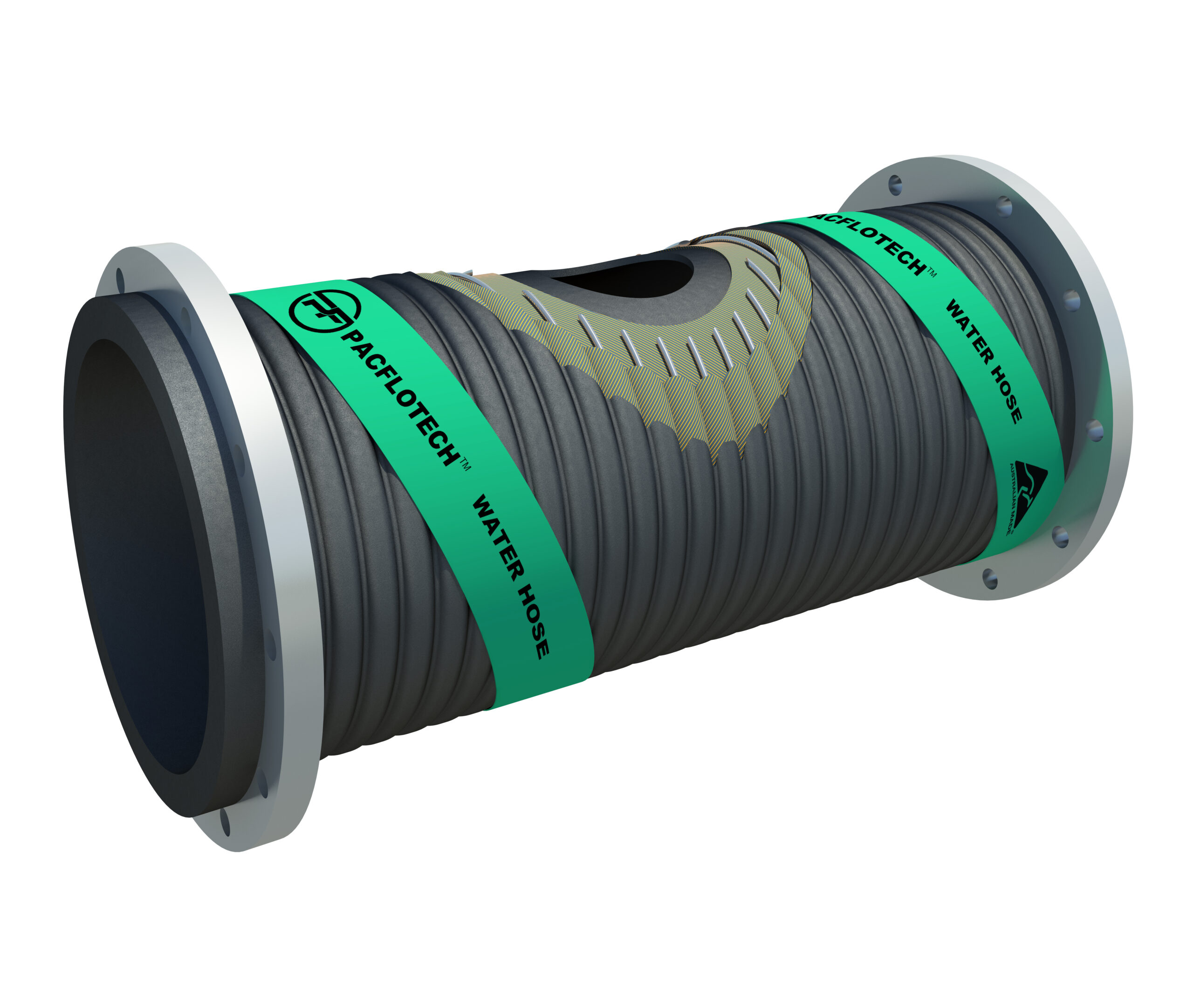

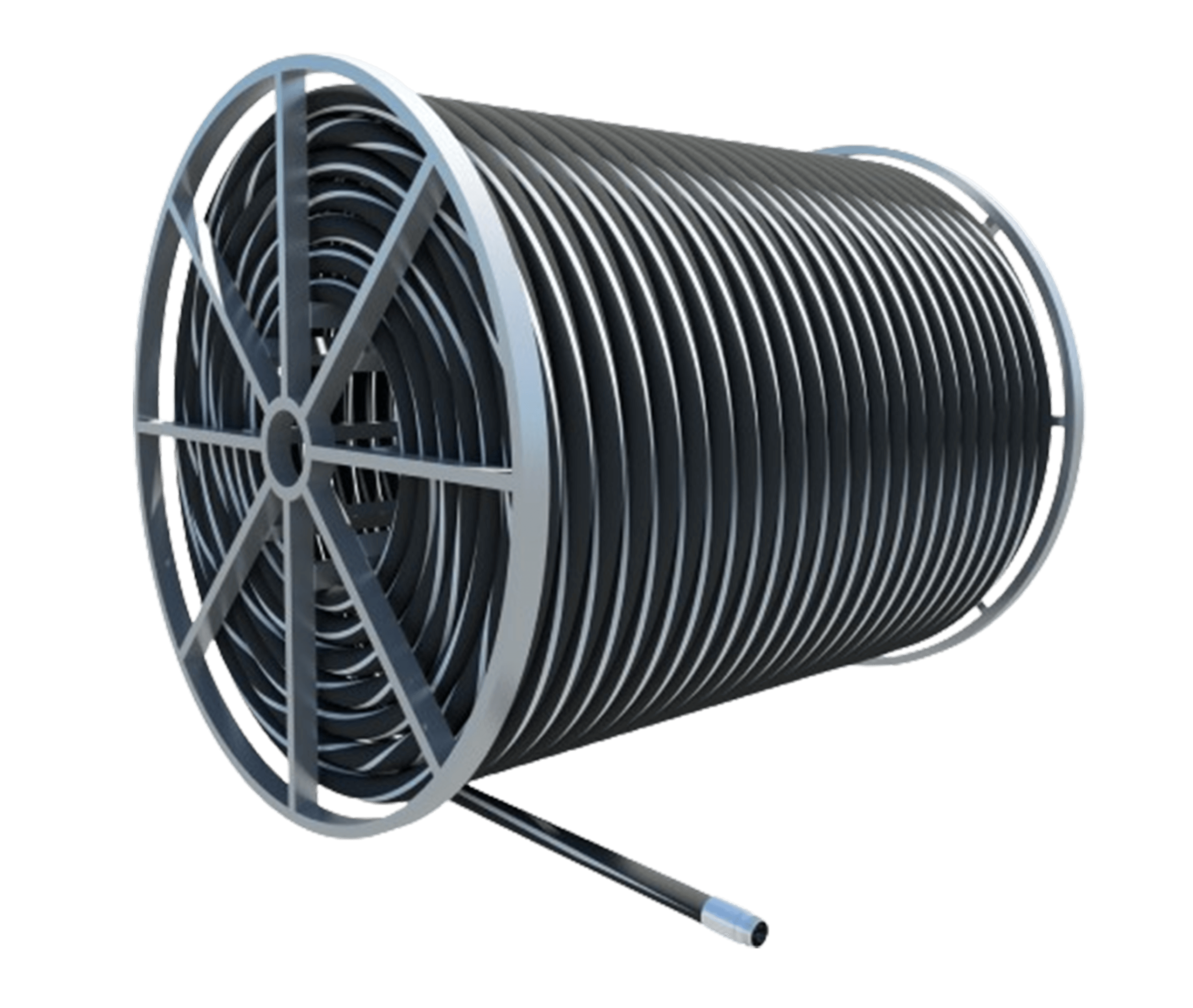

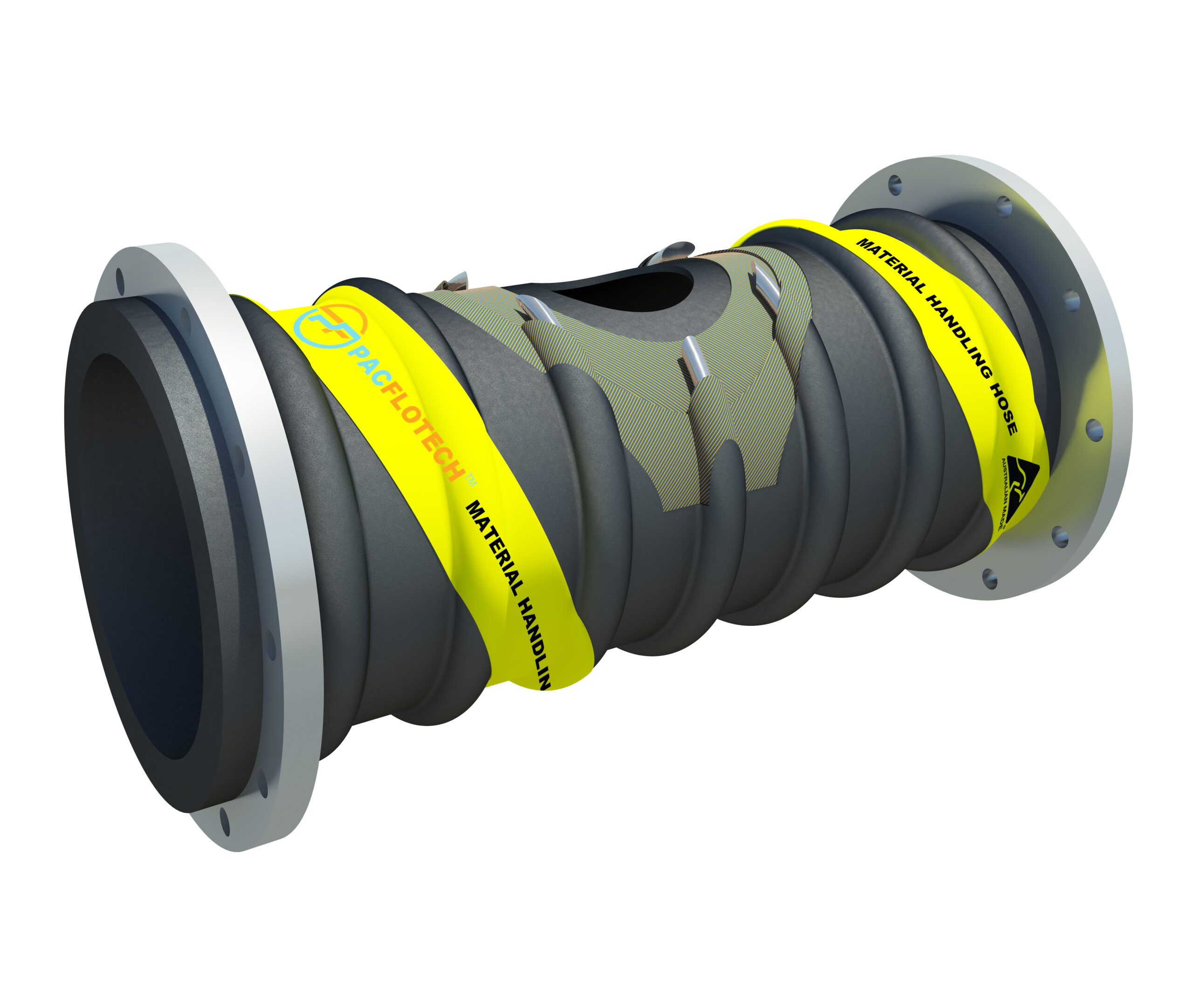

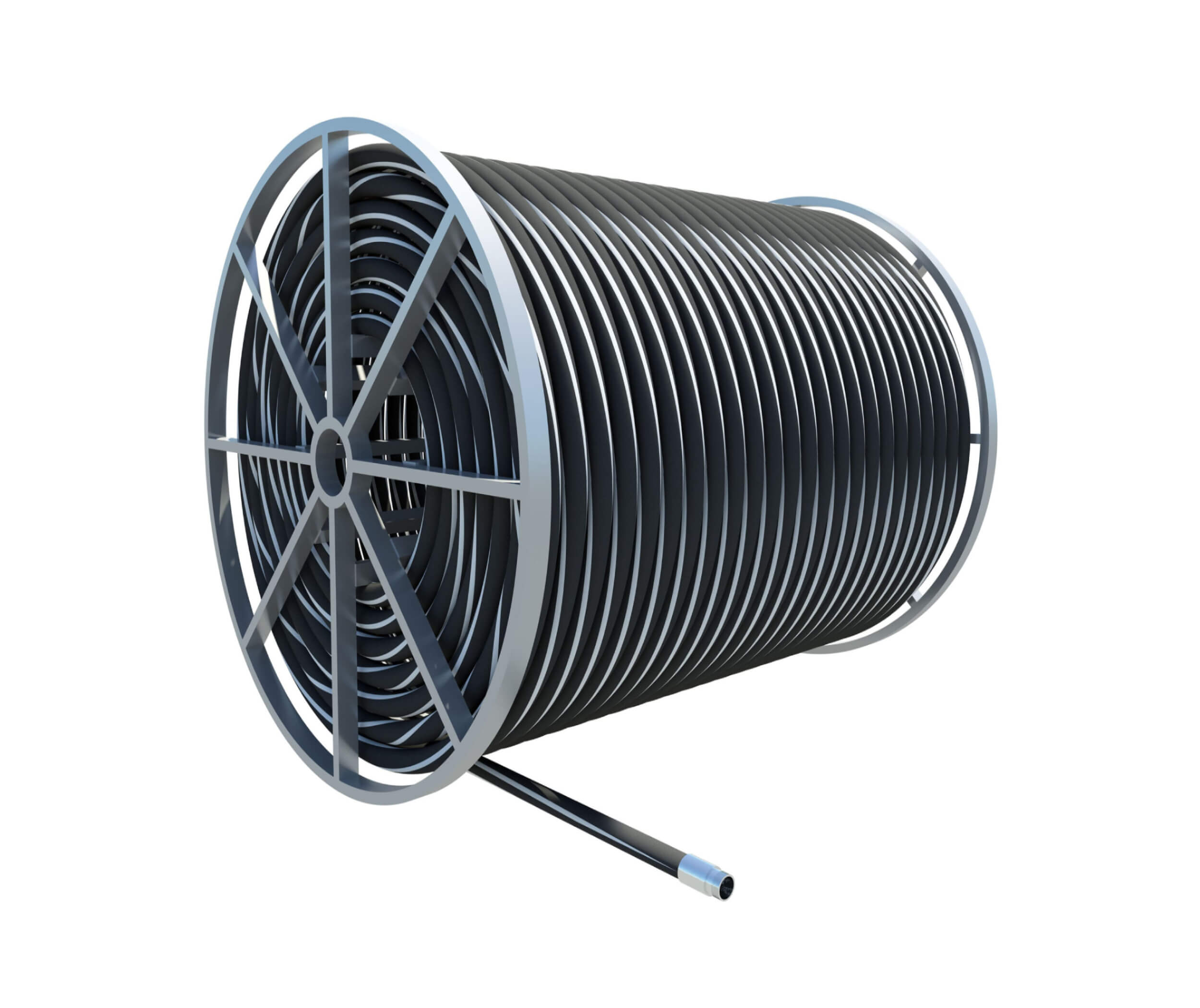

Air & Water Delivery Hose

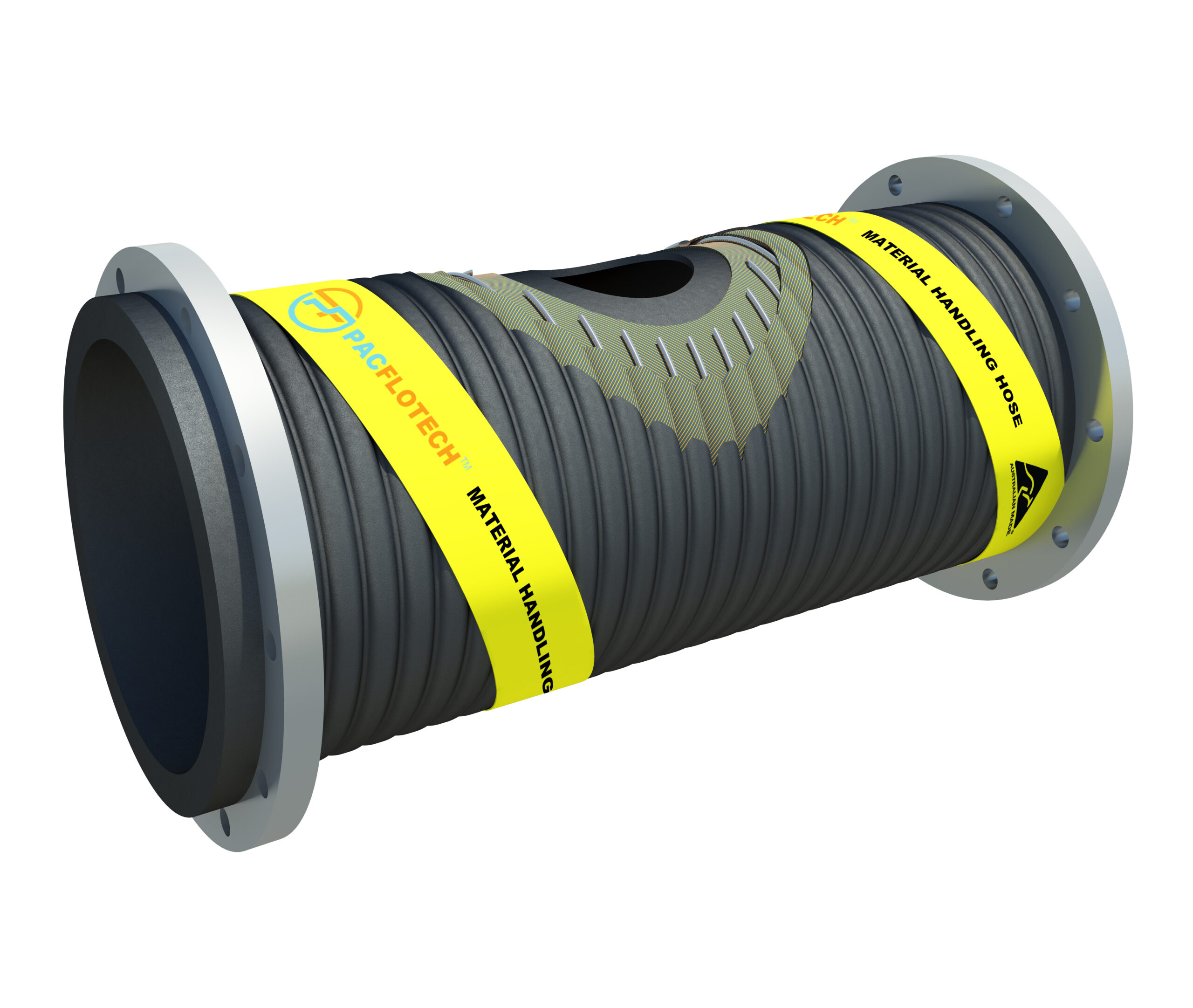

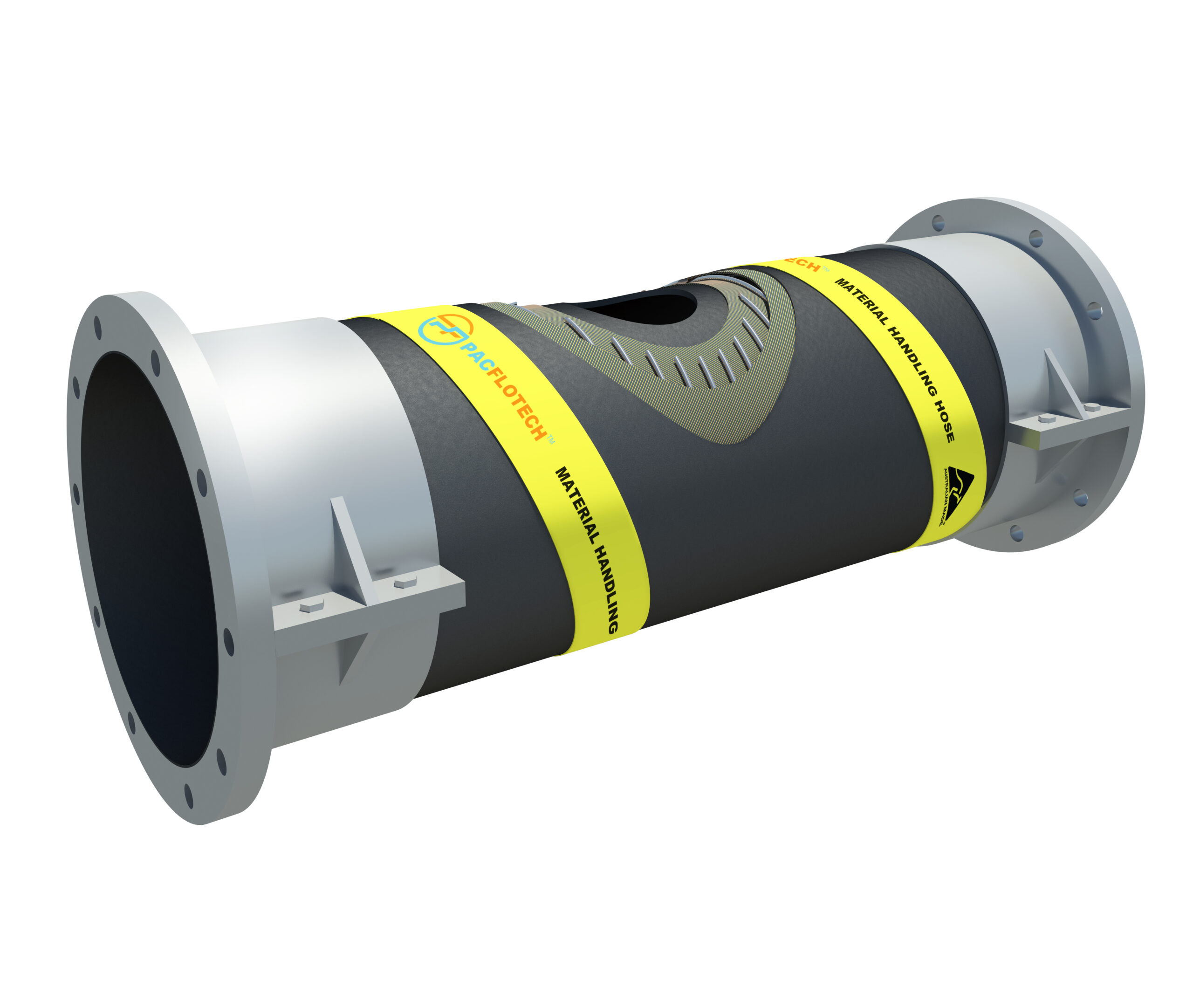

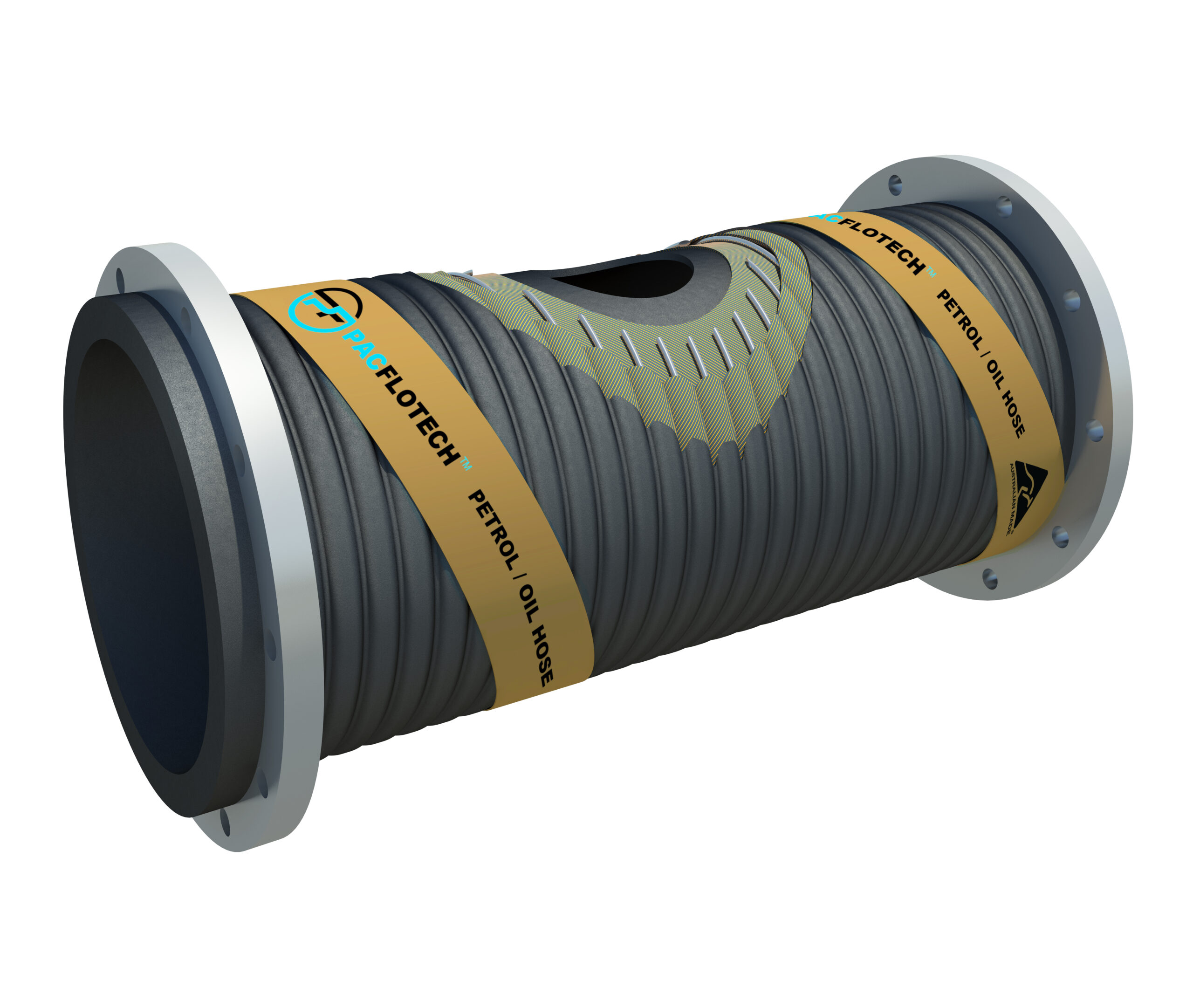

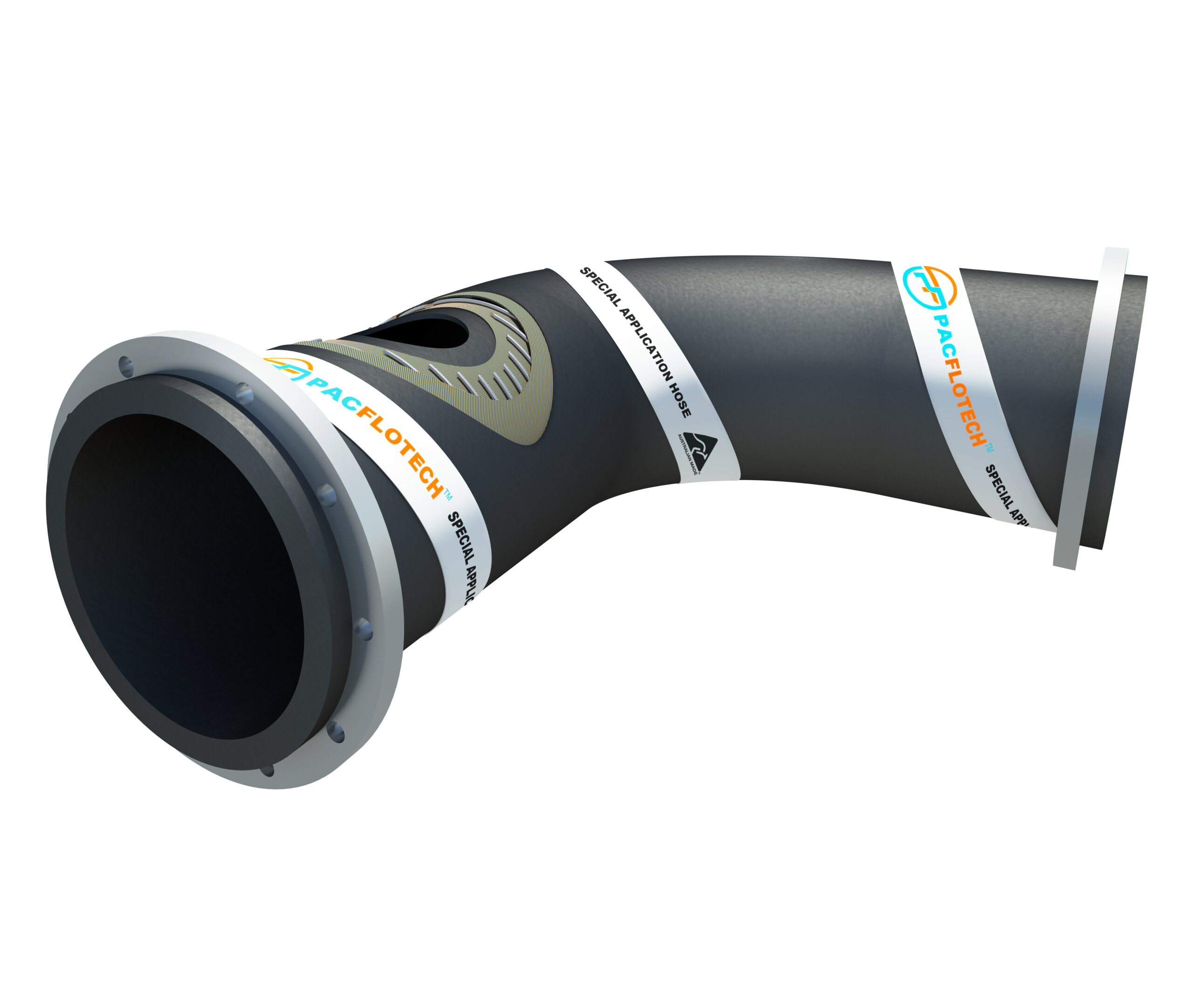

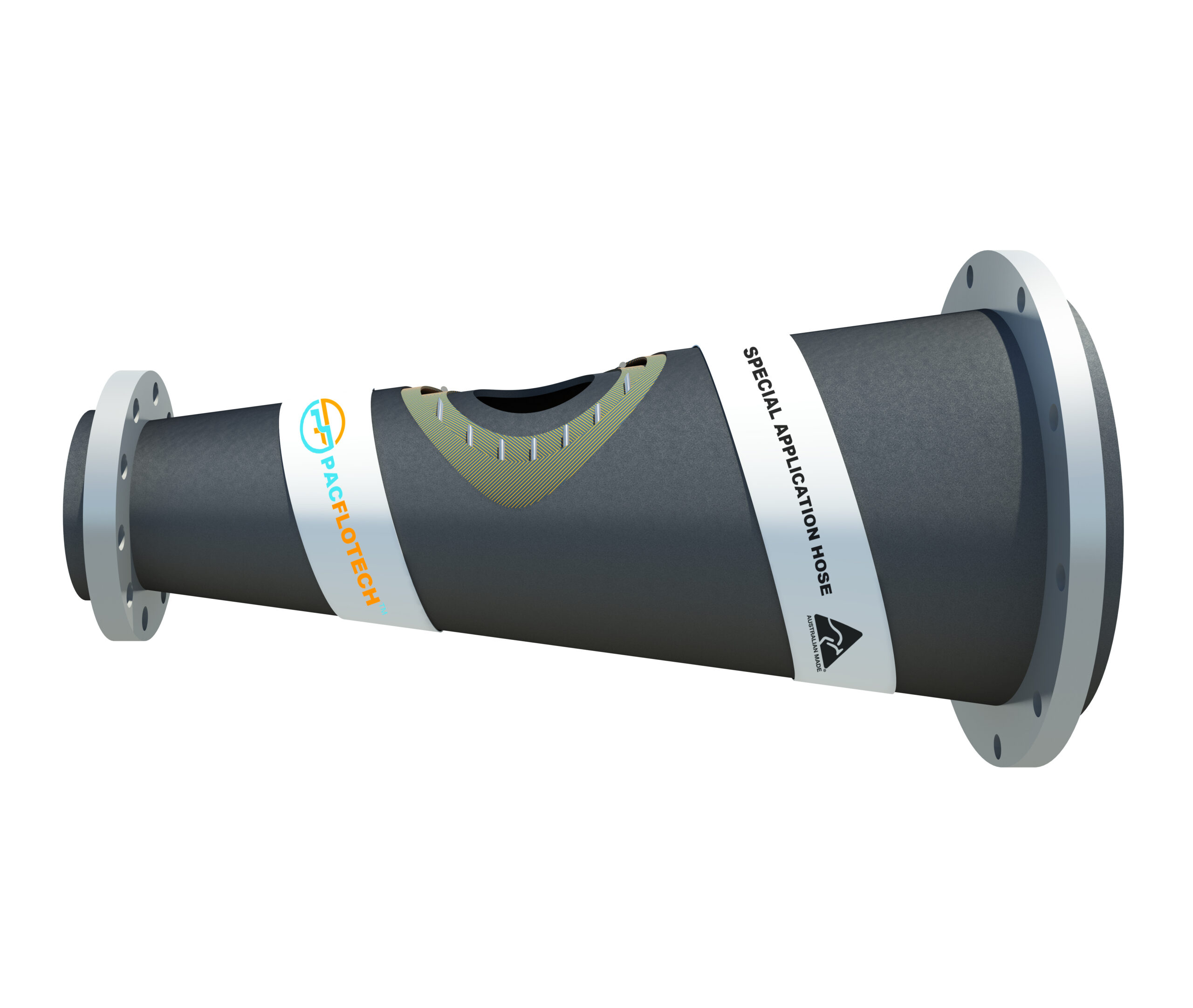

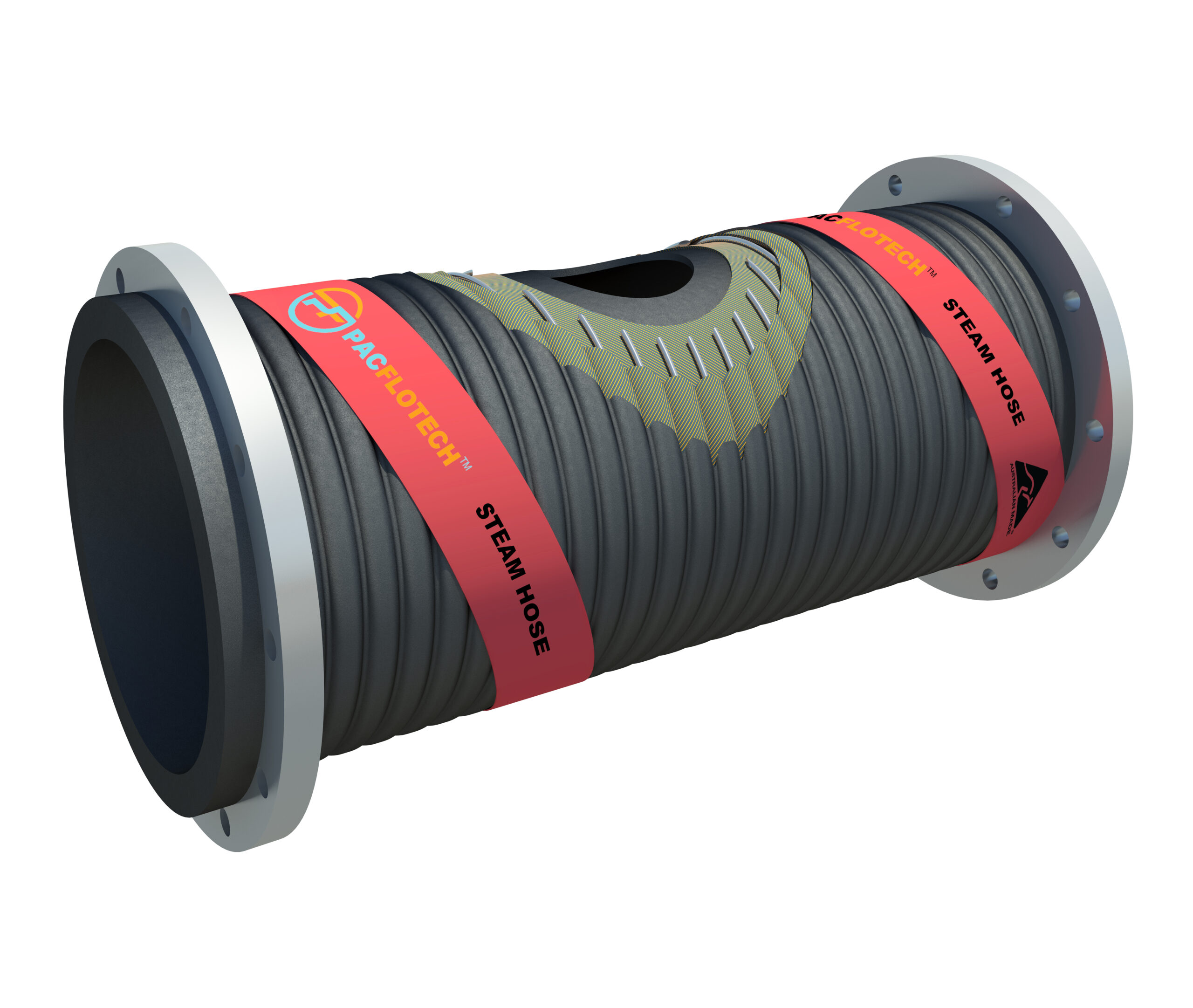

Our versatile air and water delivery hose can be used as a dewatering hose, water jet hose, hydromining hose or bunker hose. This high-quality product can also be made to meet stringent FRAS water hose standards (Fire Resistant Anti-Static), ensuring safe operation in harsh conditions. Our hoses are made from the highest quality compounds and designed for maximum durability in demanding environments, making them particularly well suited for the tough Australian climate.

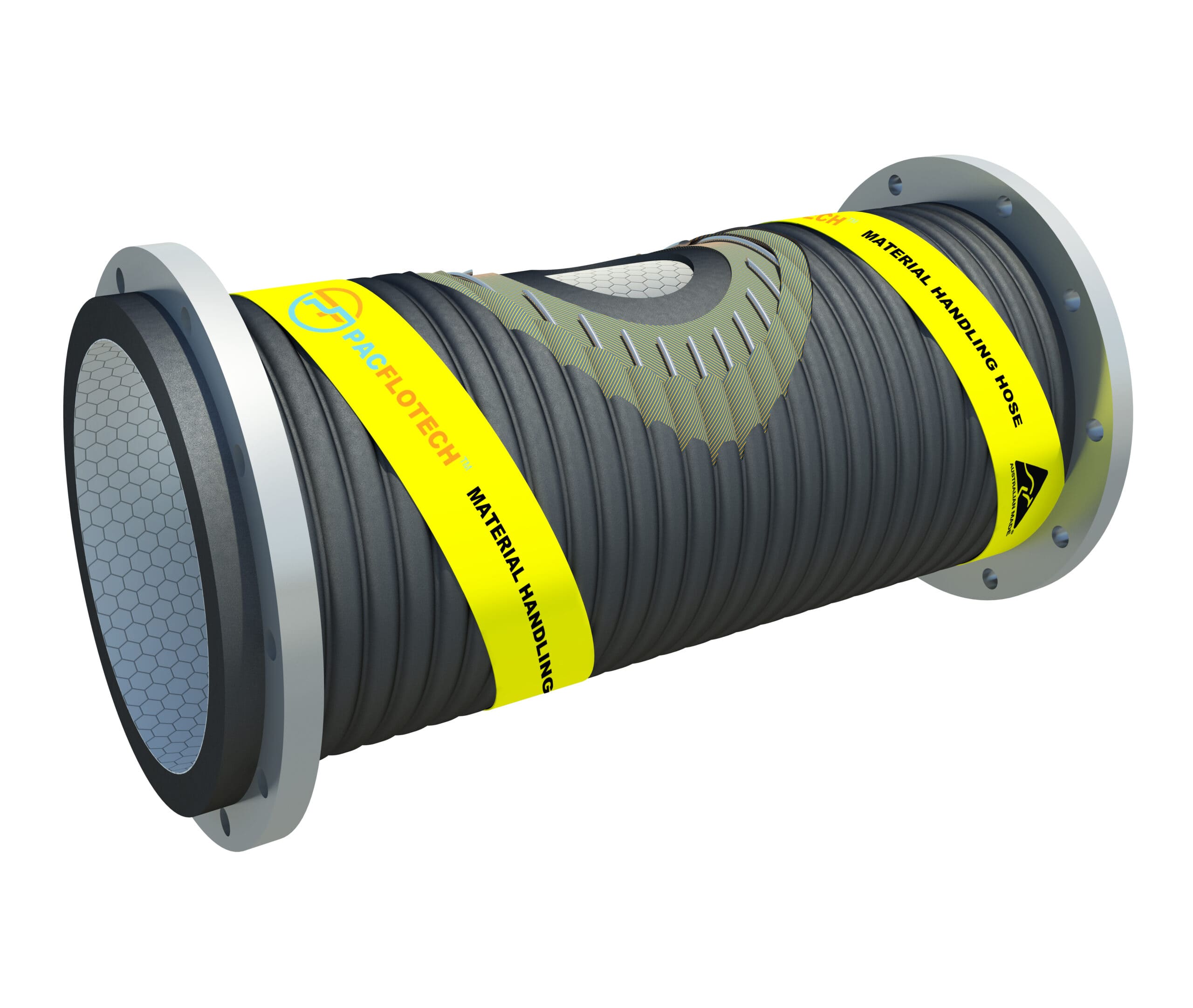

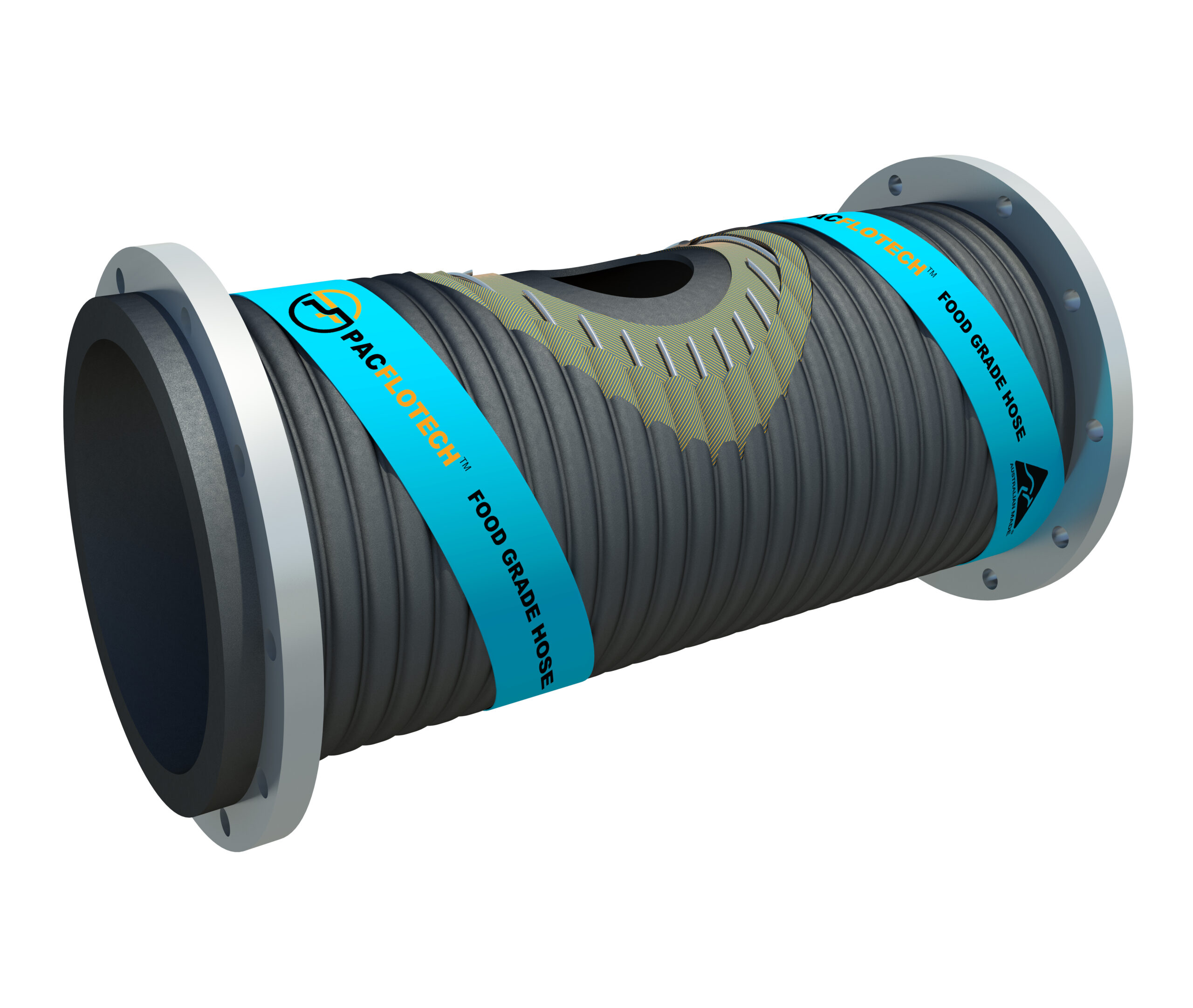

Expertise You Can Trust

With over 100 years of combined experience, Pacific Flow Technology stands as a trusted name in the rubber hose manufacturing industry, primarily catering to the mining sector. We provide the highest quality air and water delivery hose solutions alongside a comprehensive range of services, including custom design, technical support and pressure testing. These services ensure our products meets the highest industry standards, reinforcing our commitment to delivering hoses that are both resilient and reliable in extreme conditions. Whether you need a bunkering hose, water jet hose or dewatering hose, you can rely on our products to deliver safety, longevity and optimal performance.