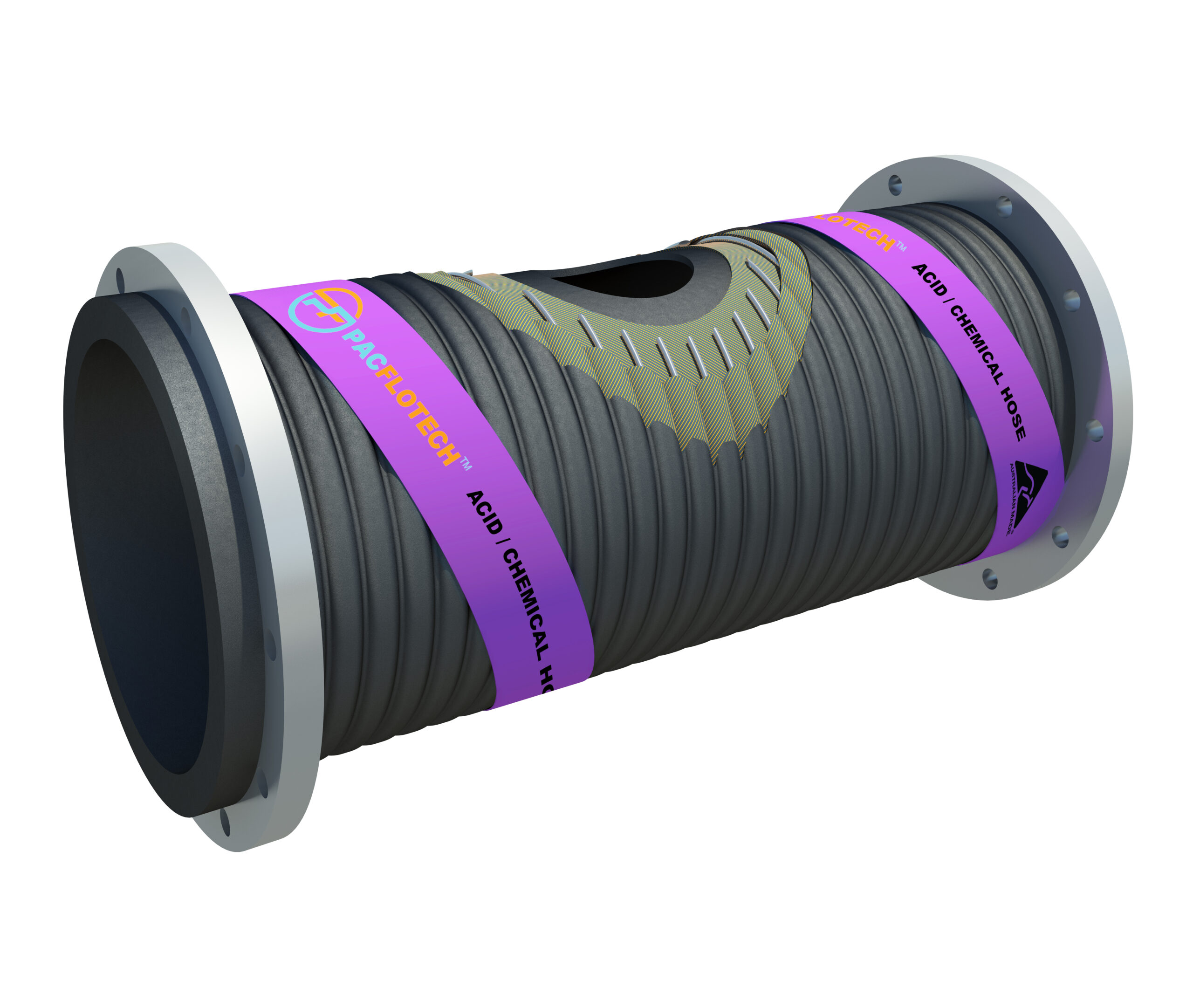

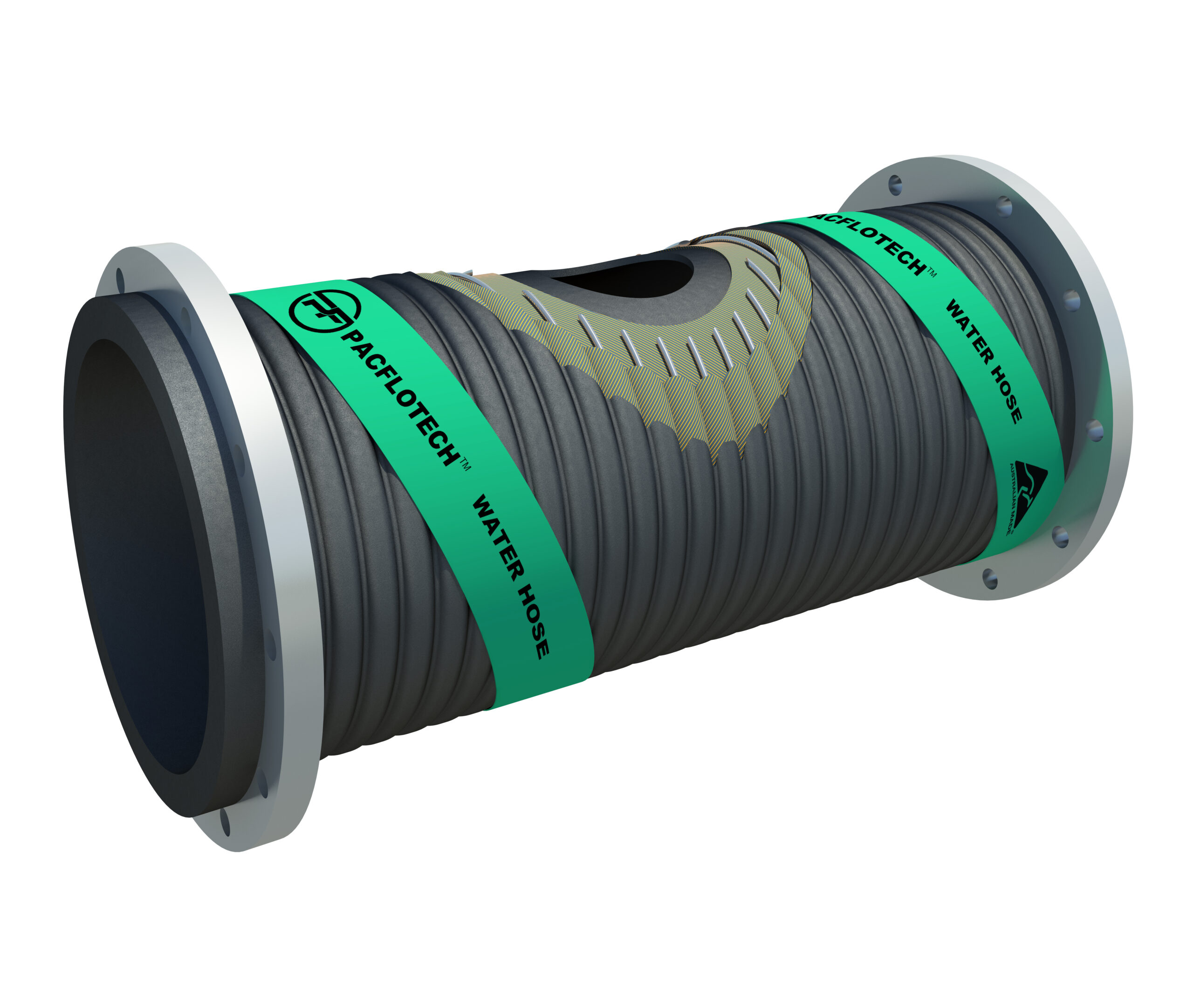

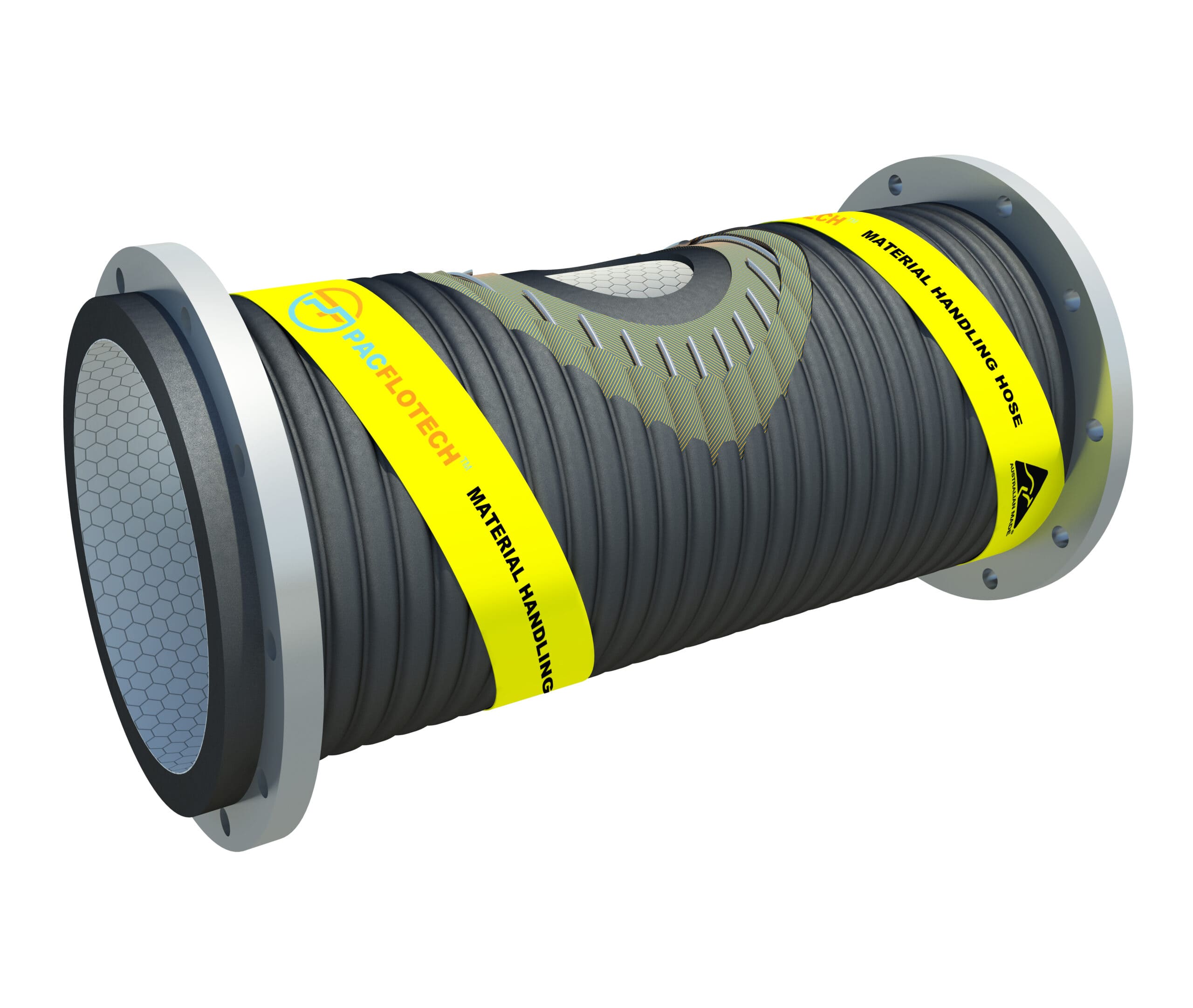

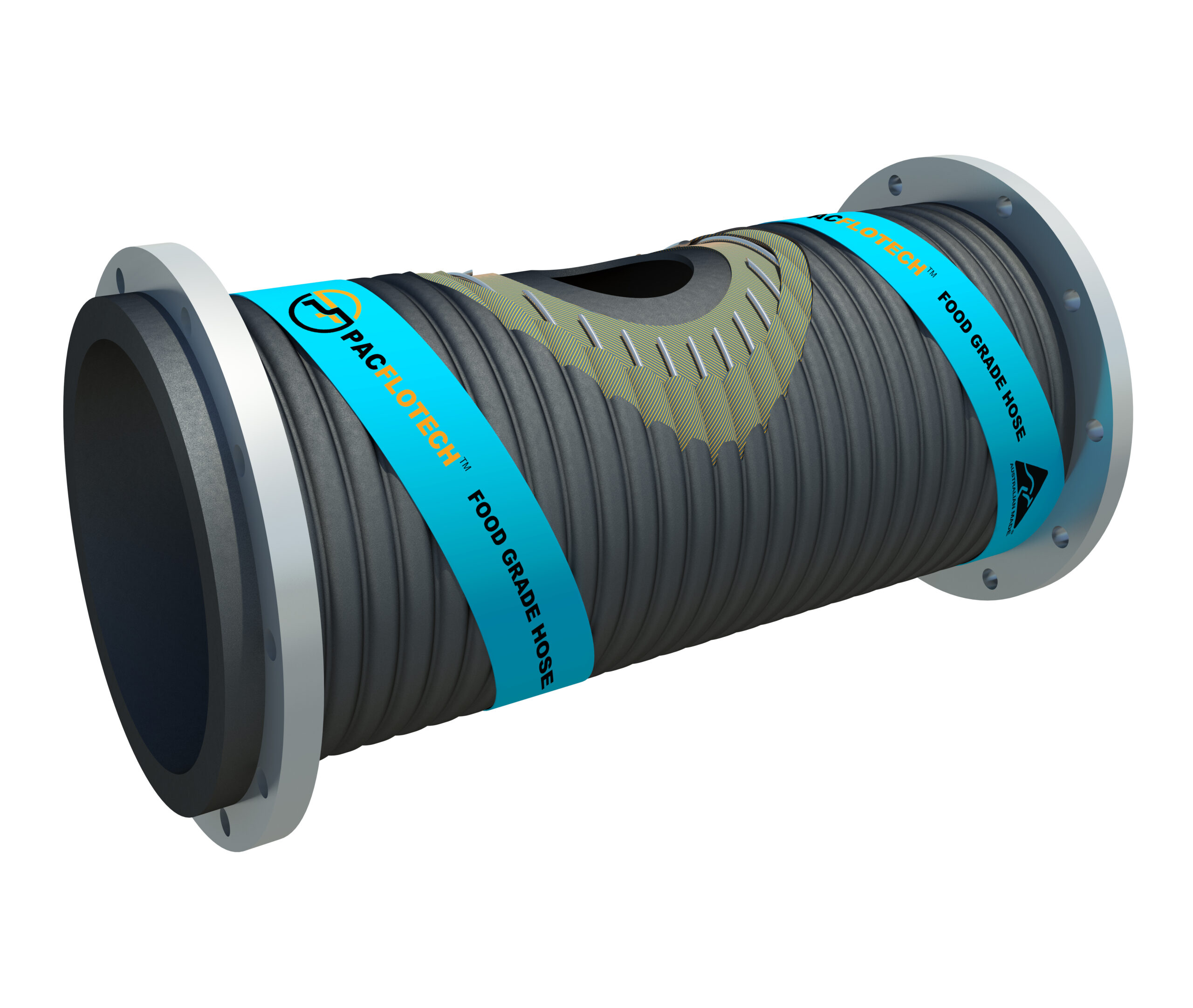

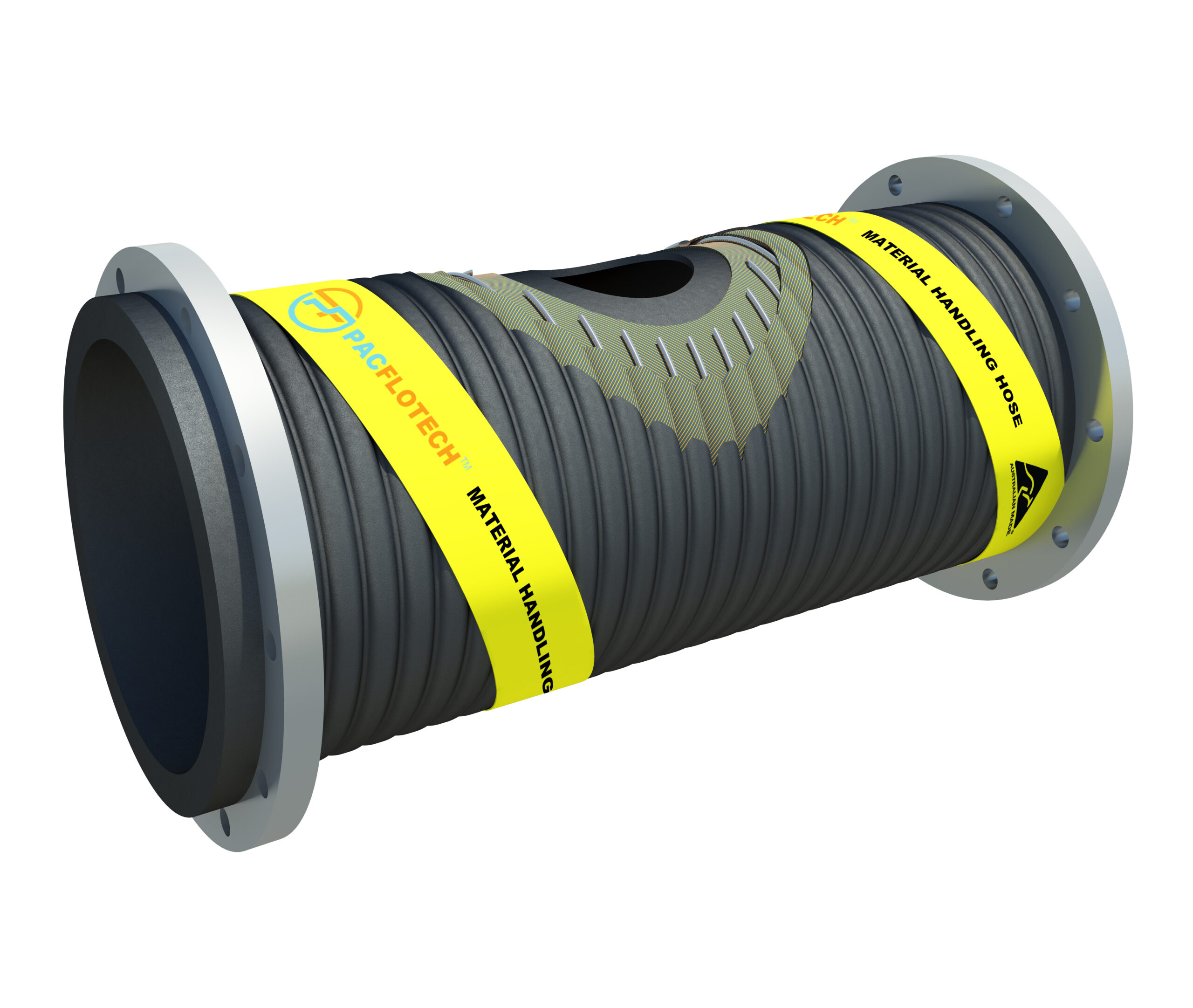

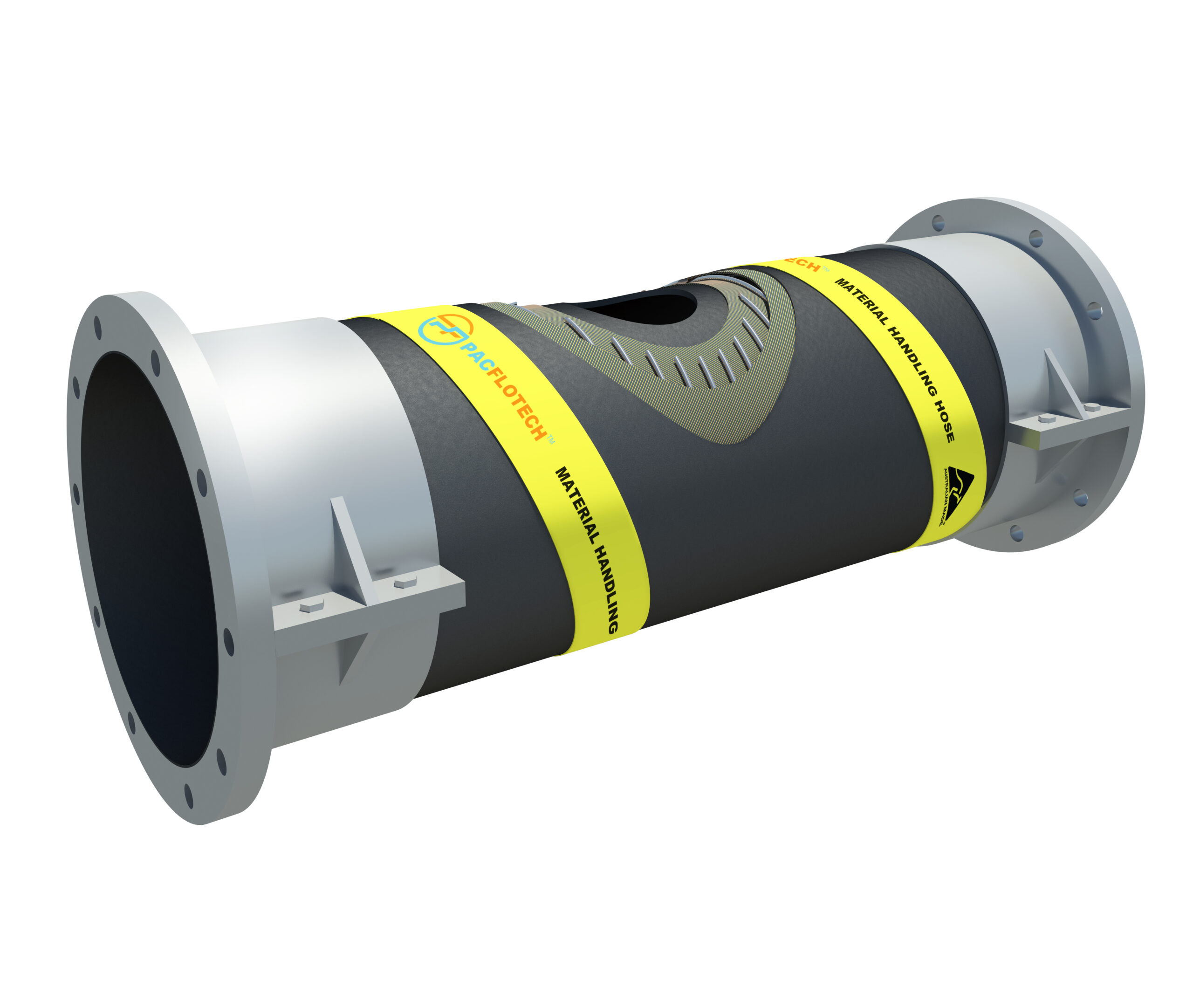

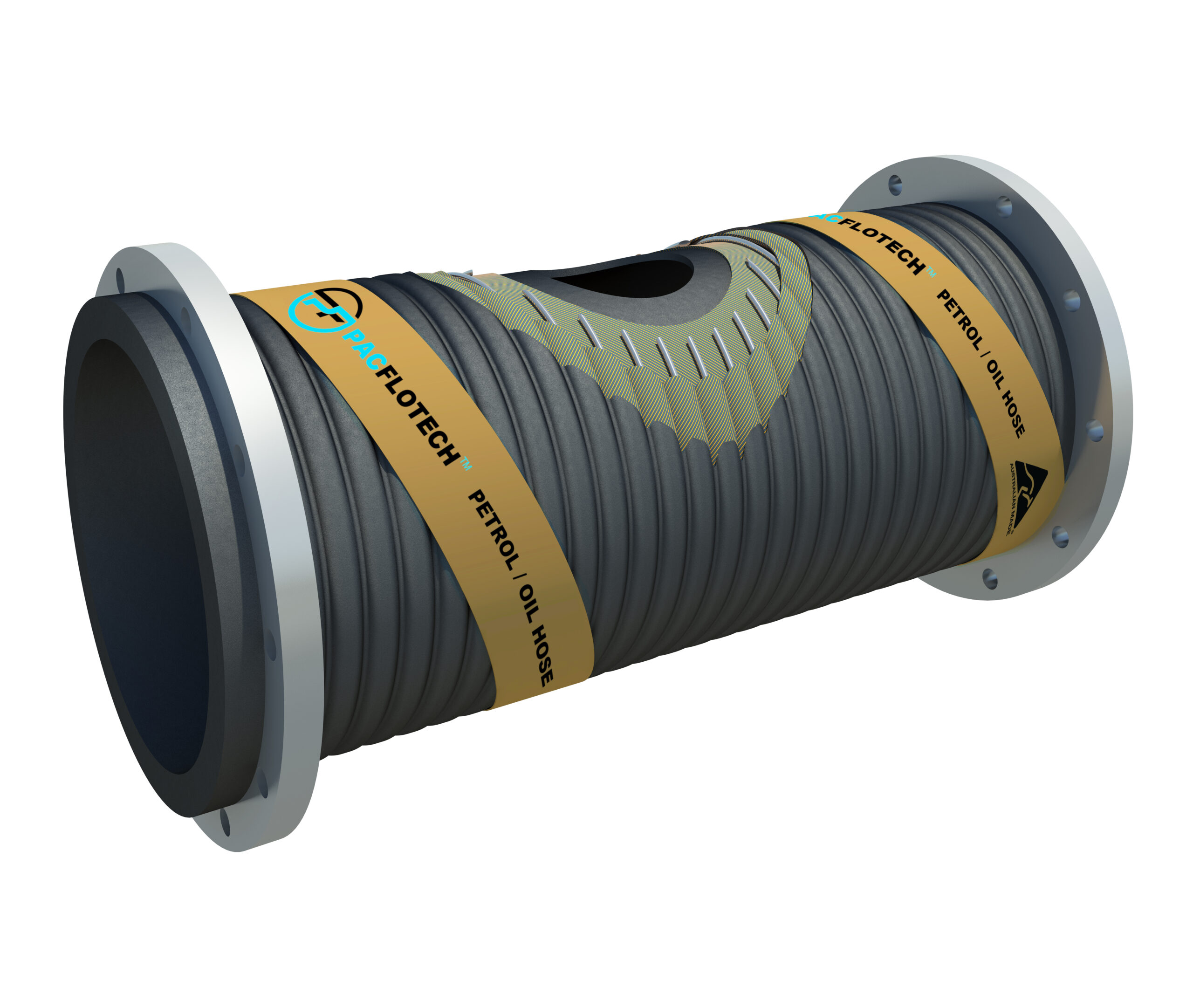

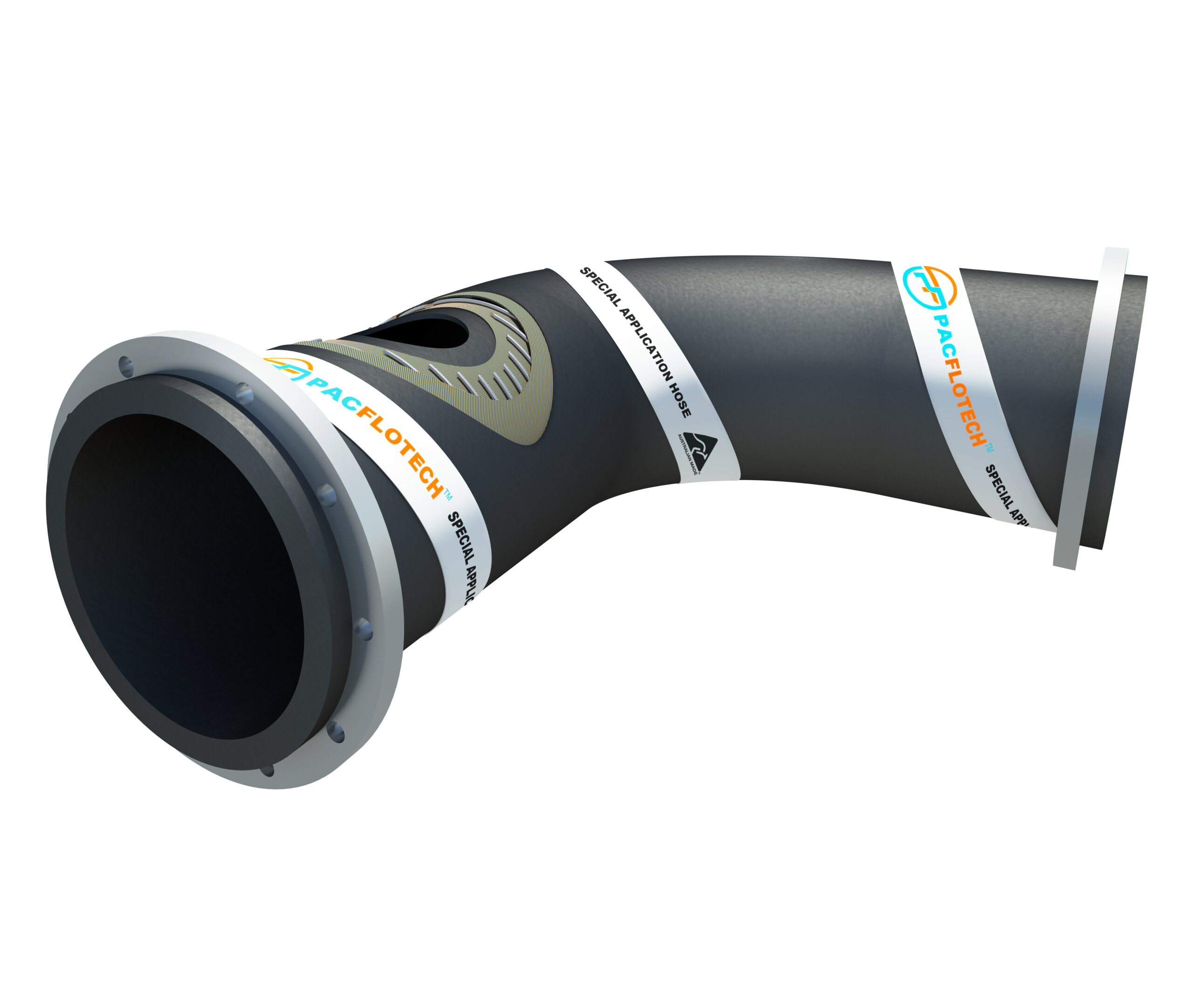

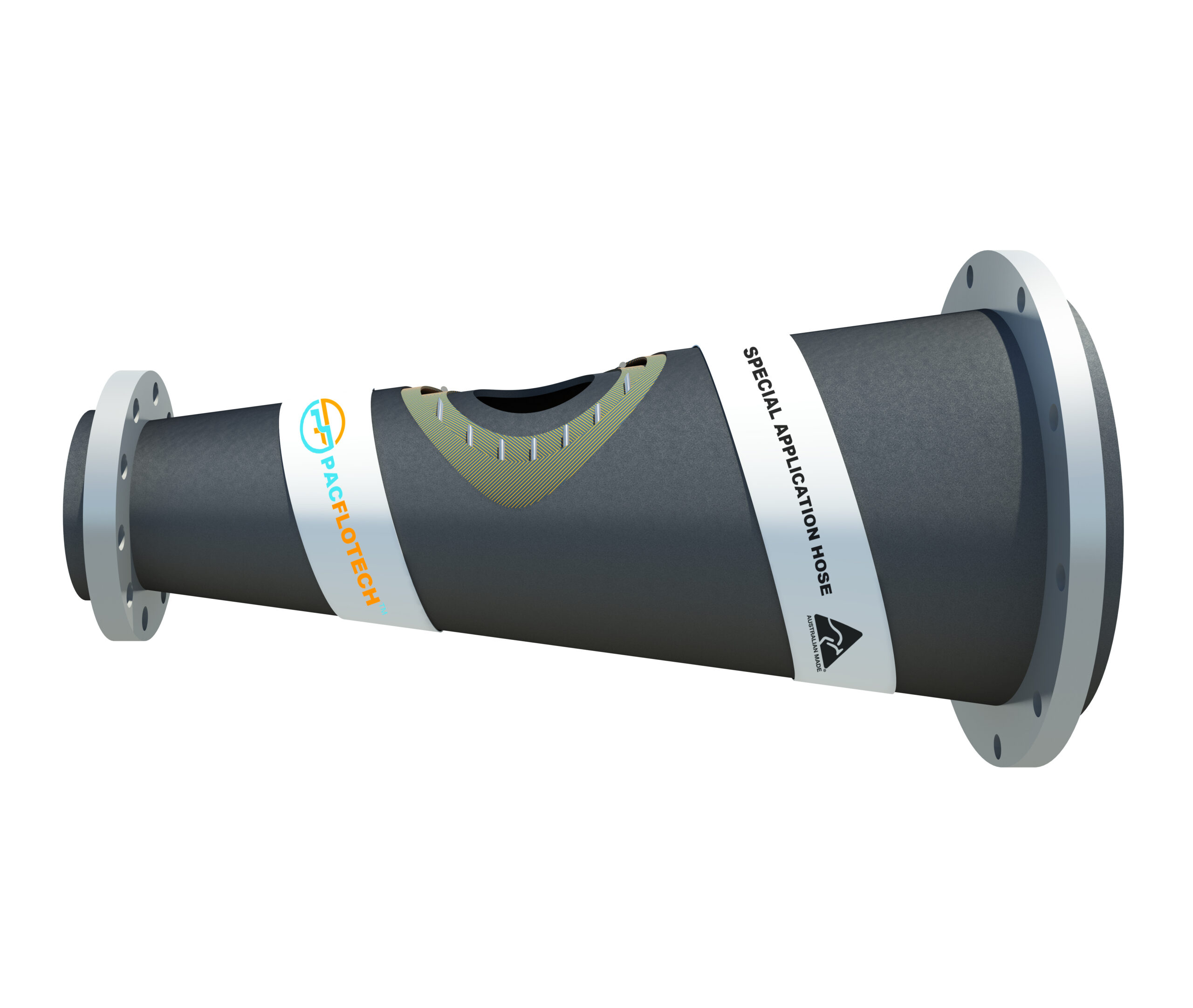

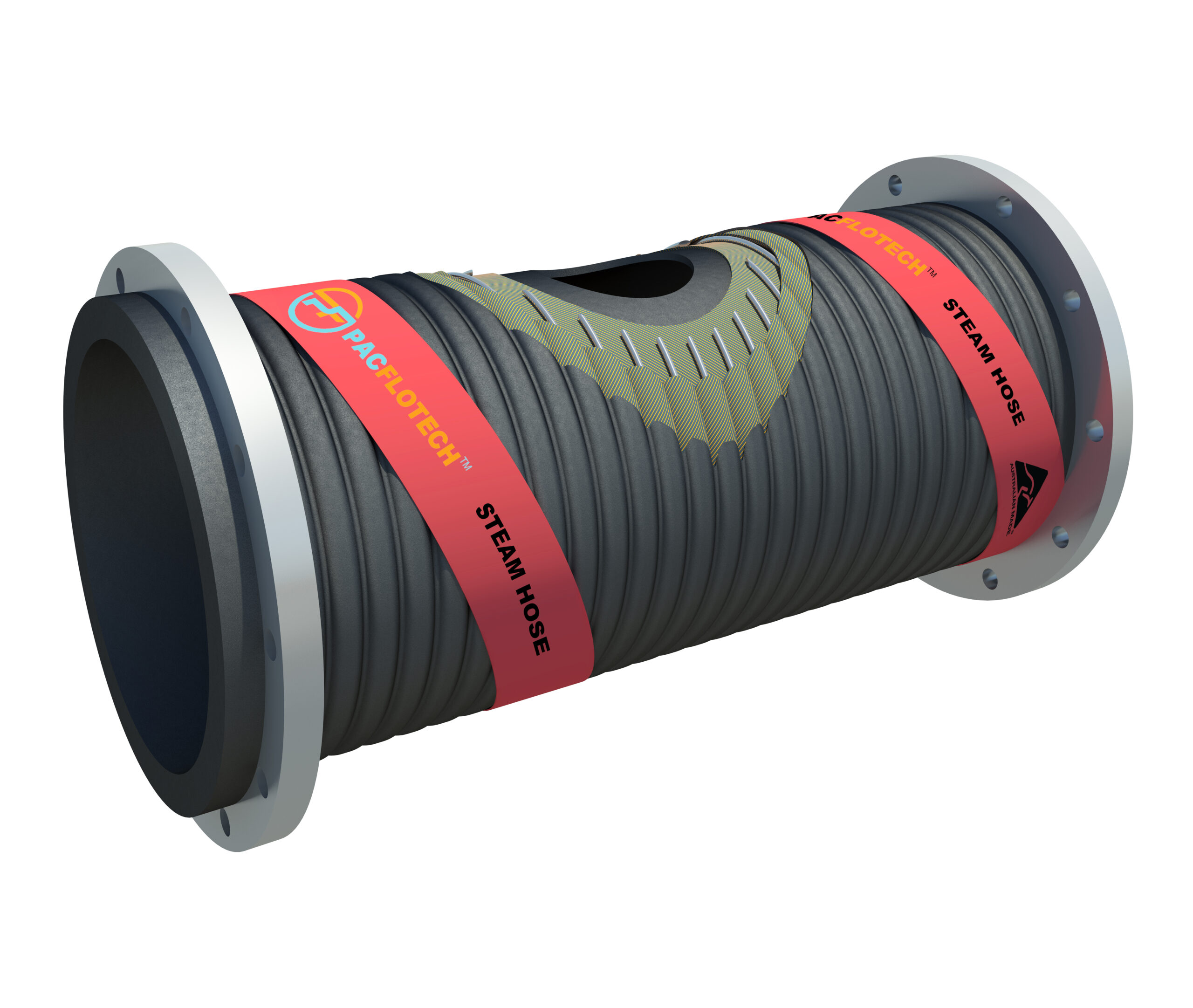

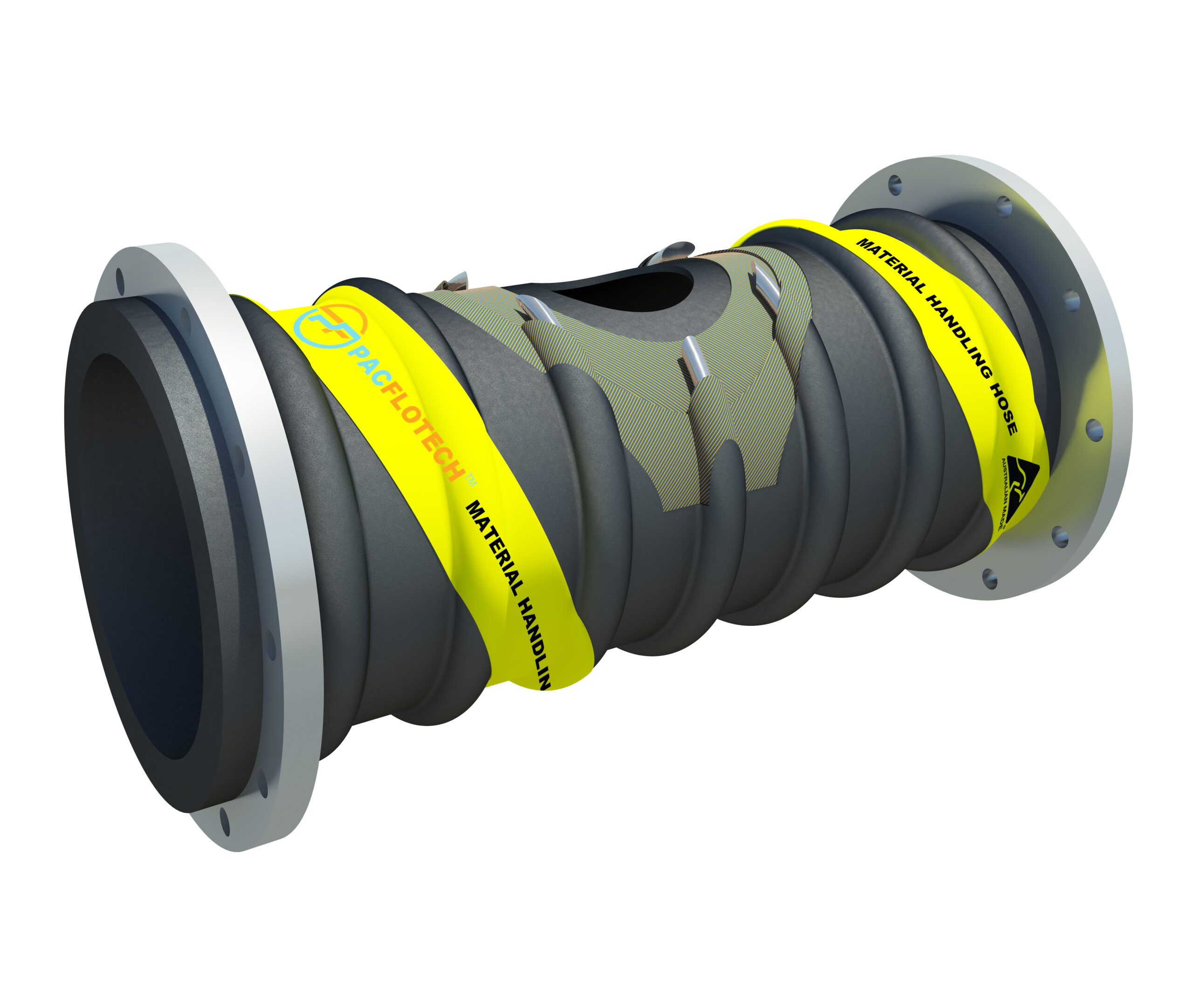

Mining Delivery Hose

Designed for the rigorous demands of the mining industry, our mining delivery hose offers industry-leading performance in abrasion loss, making it ideal for transporting abrasive slurries in various applications. Whether handling coarse rock particles or fine mineral slurries, our hoses provide superior reliability and extended longevity, helping to minimise downtime and deliver consistent performance even in the harshest environments.

Advanced Liner Technology for Superior Performance

Our mining delivery hose solutions feature advanced liner technology to address the demands of sand mining, slurry transportation and mining materials handling. Our hoses can also be used in a slurry pipeline or cyclone pipe. From abrasion-resistant hoses for suction dredge mining to hoses designed for spiral feed piping, you can rest assured each solution delivers exceptional wear resistance. We also offer hot cure butyl tube liners to enhance temperature and chemical resistance without compromising abrasion performance. Whether you need a slurry hose, a manifold mining hose or any other high-performance abrasion resistant hose, we can provide a reliable solution.