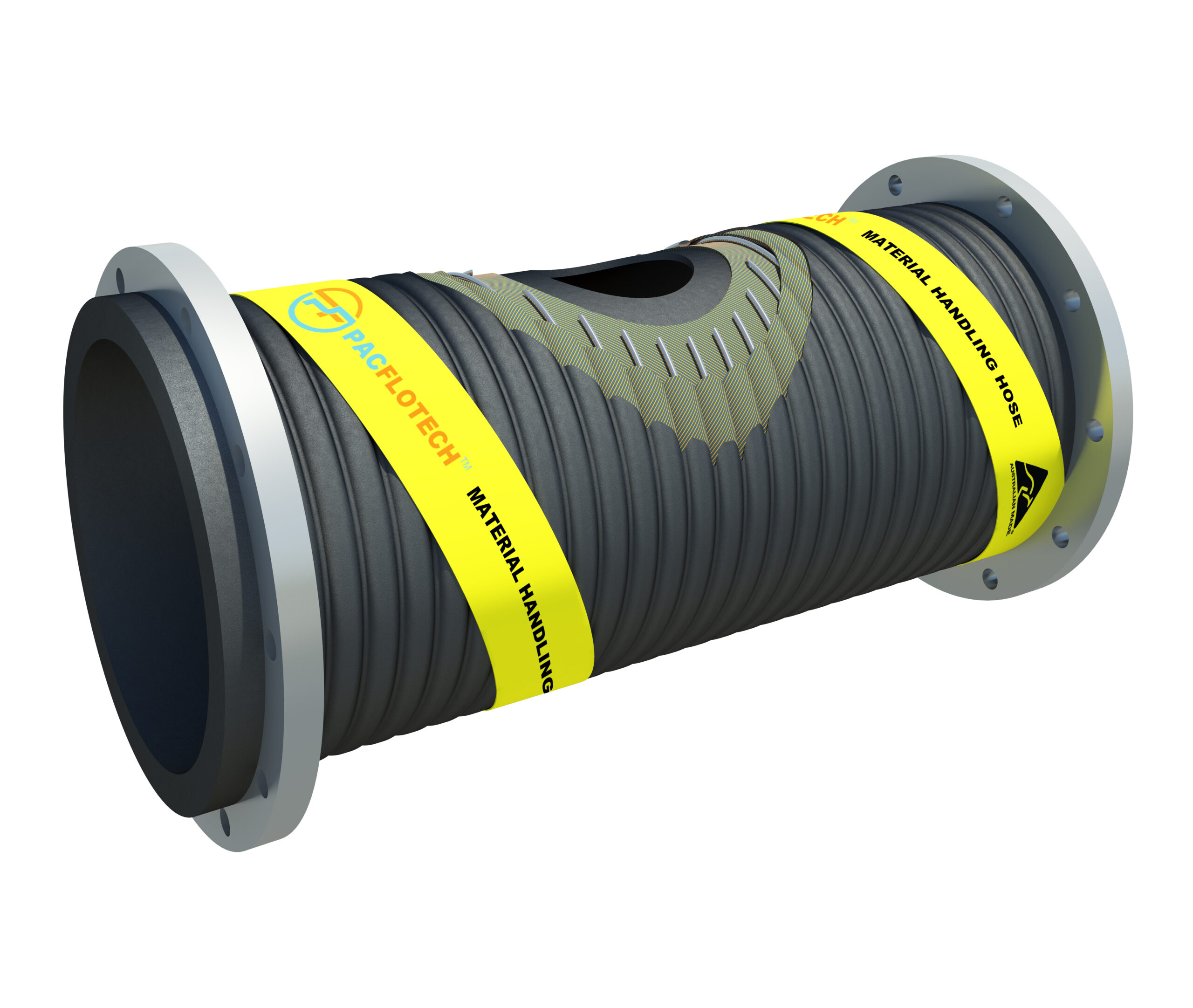

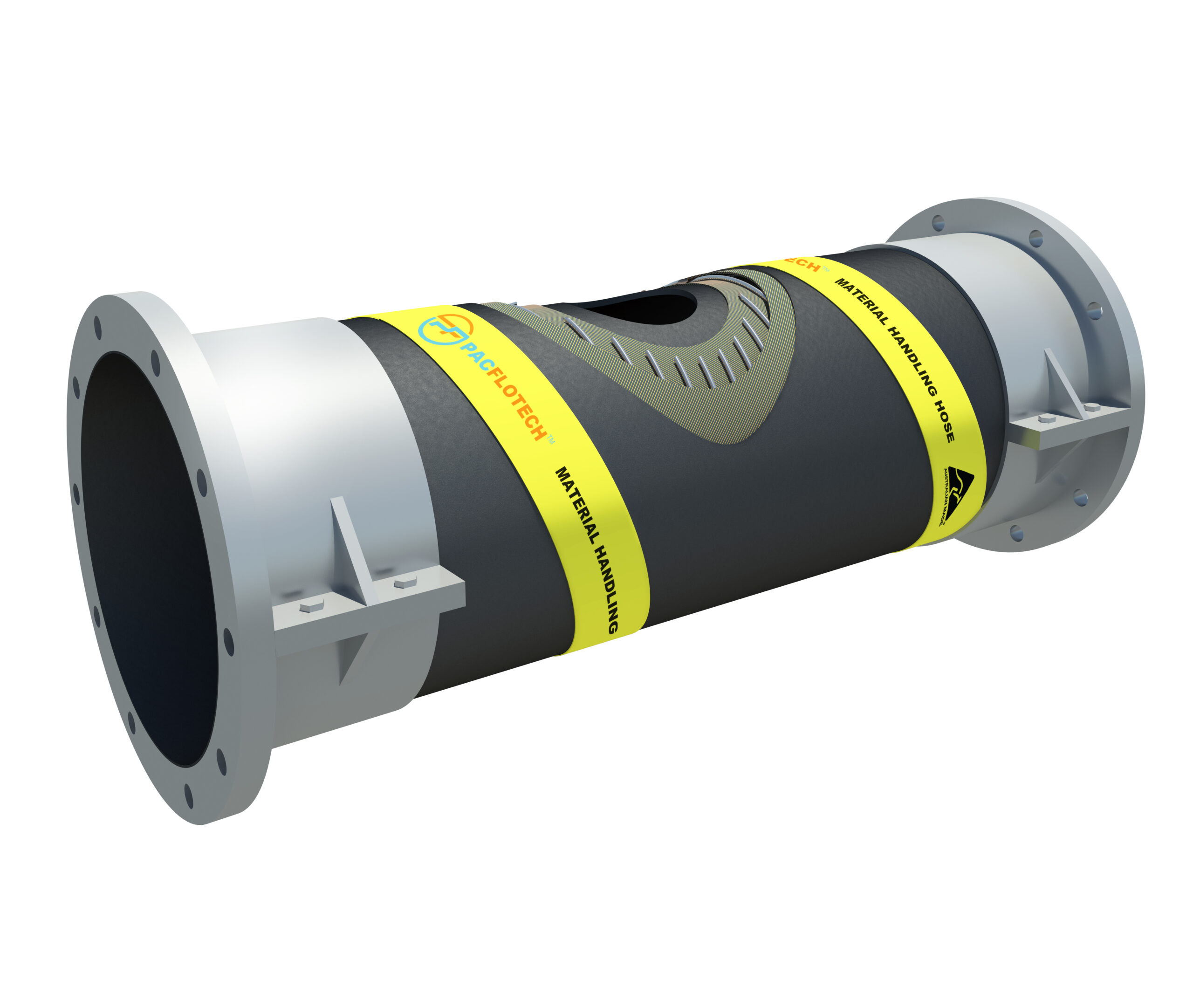

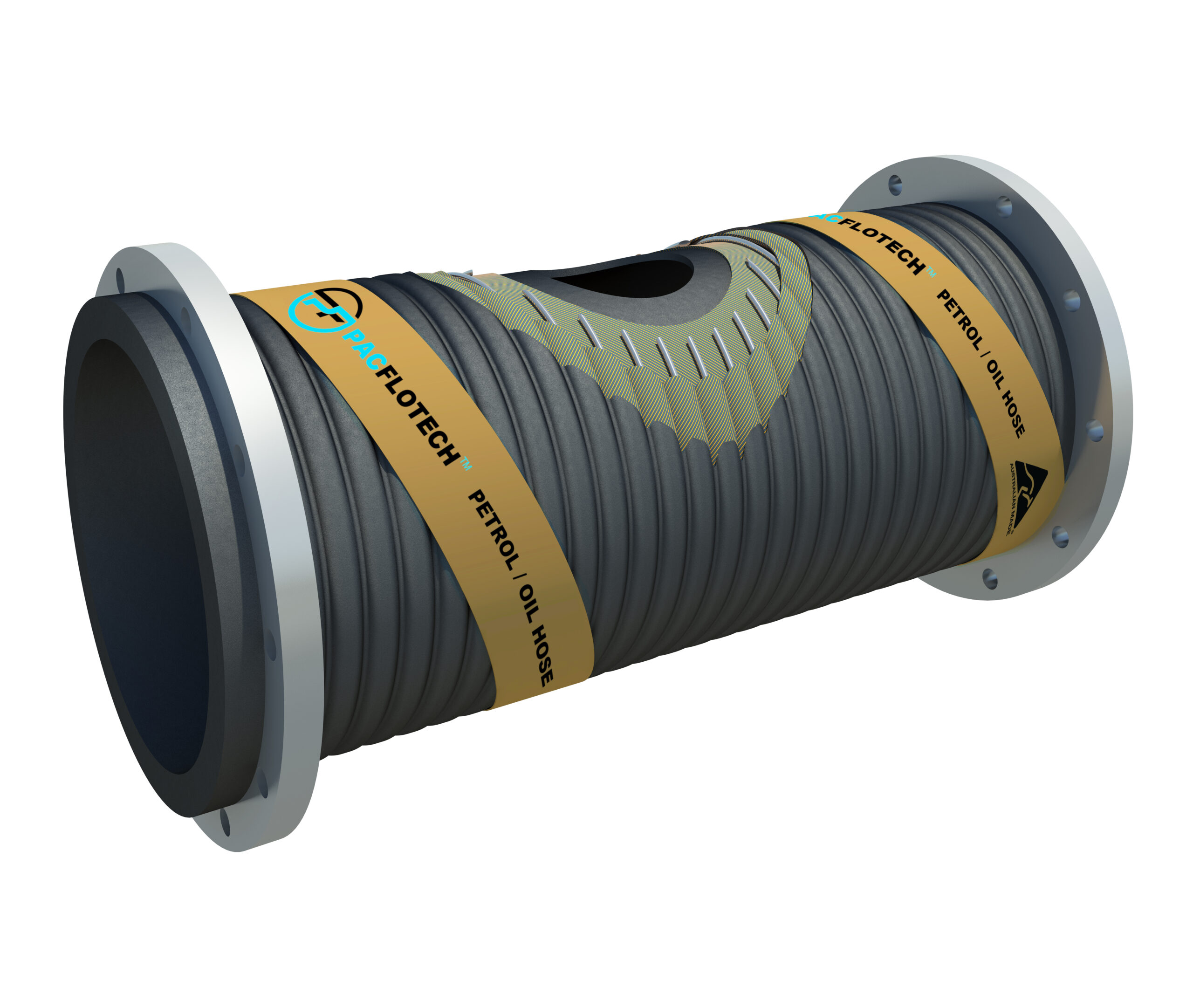

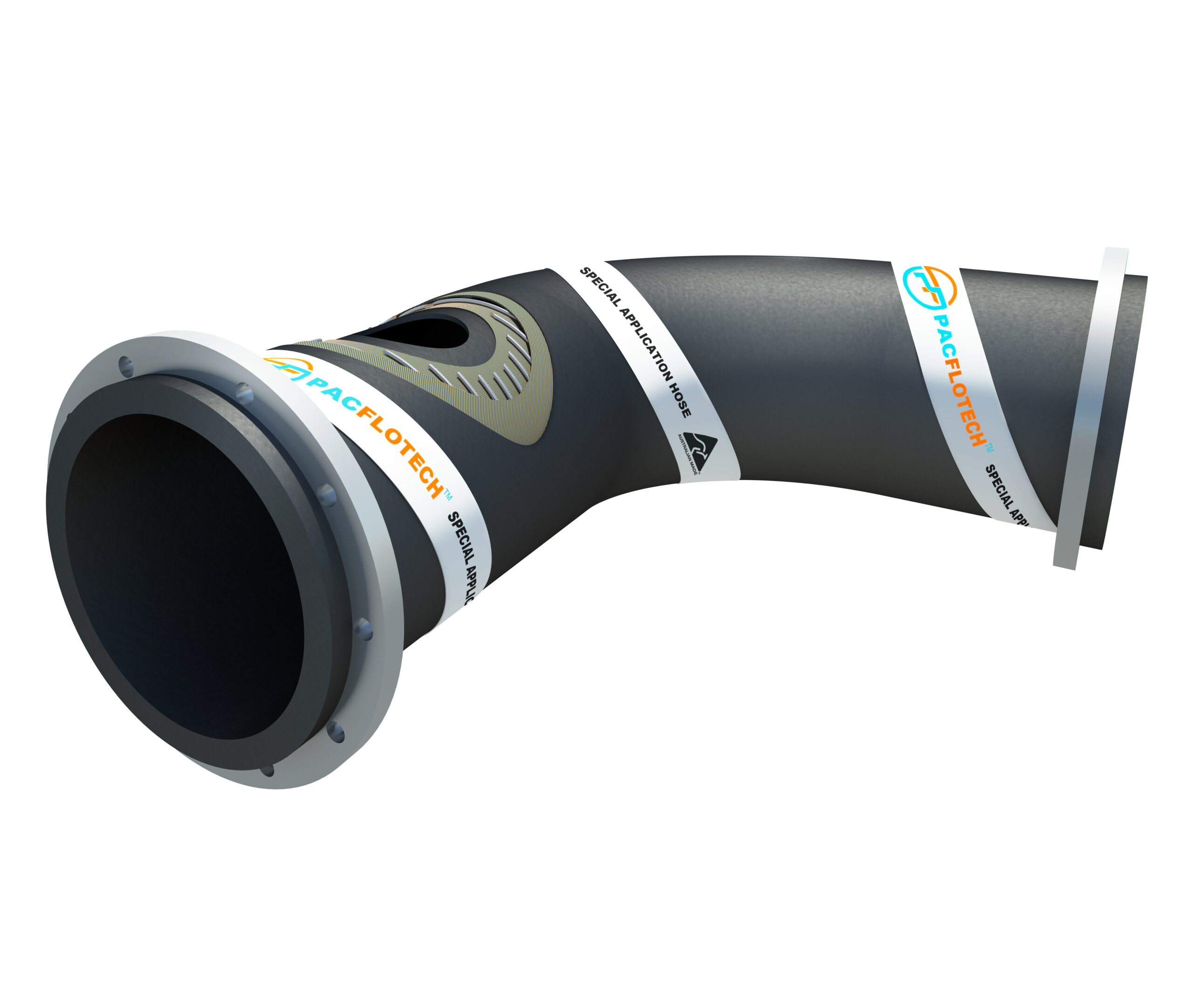

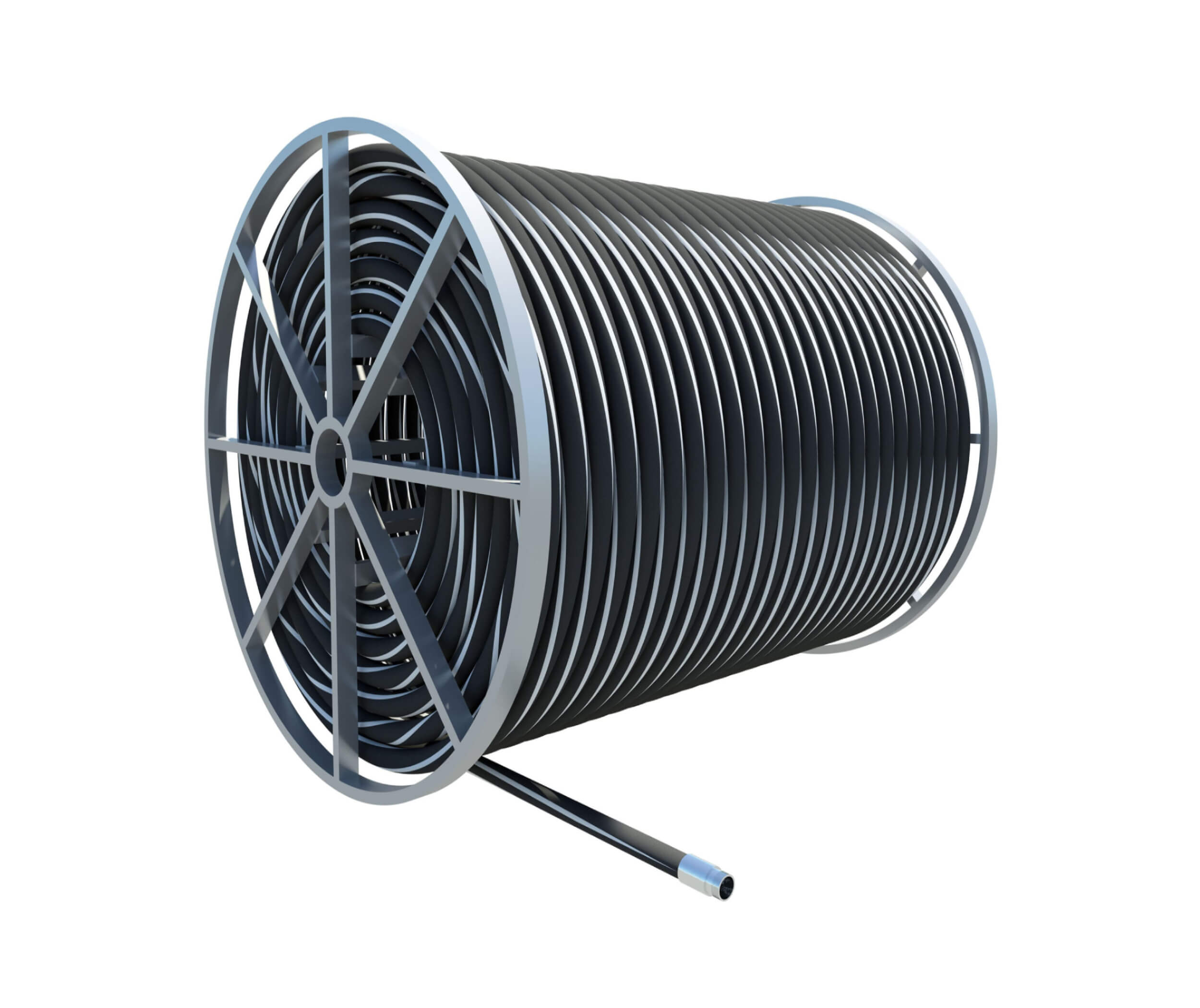

Our pre-formed bends hose allows for a tighter bend radius than what can be achieved with straight-length hose, making it ideal for applications where space is limited or precise routing is required. This design minimises stress on the hose, ensuring reliable performance in demanding conditions.

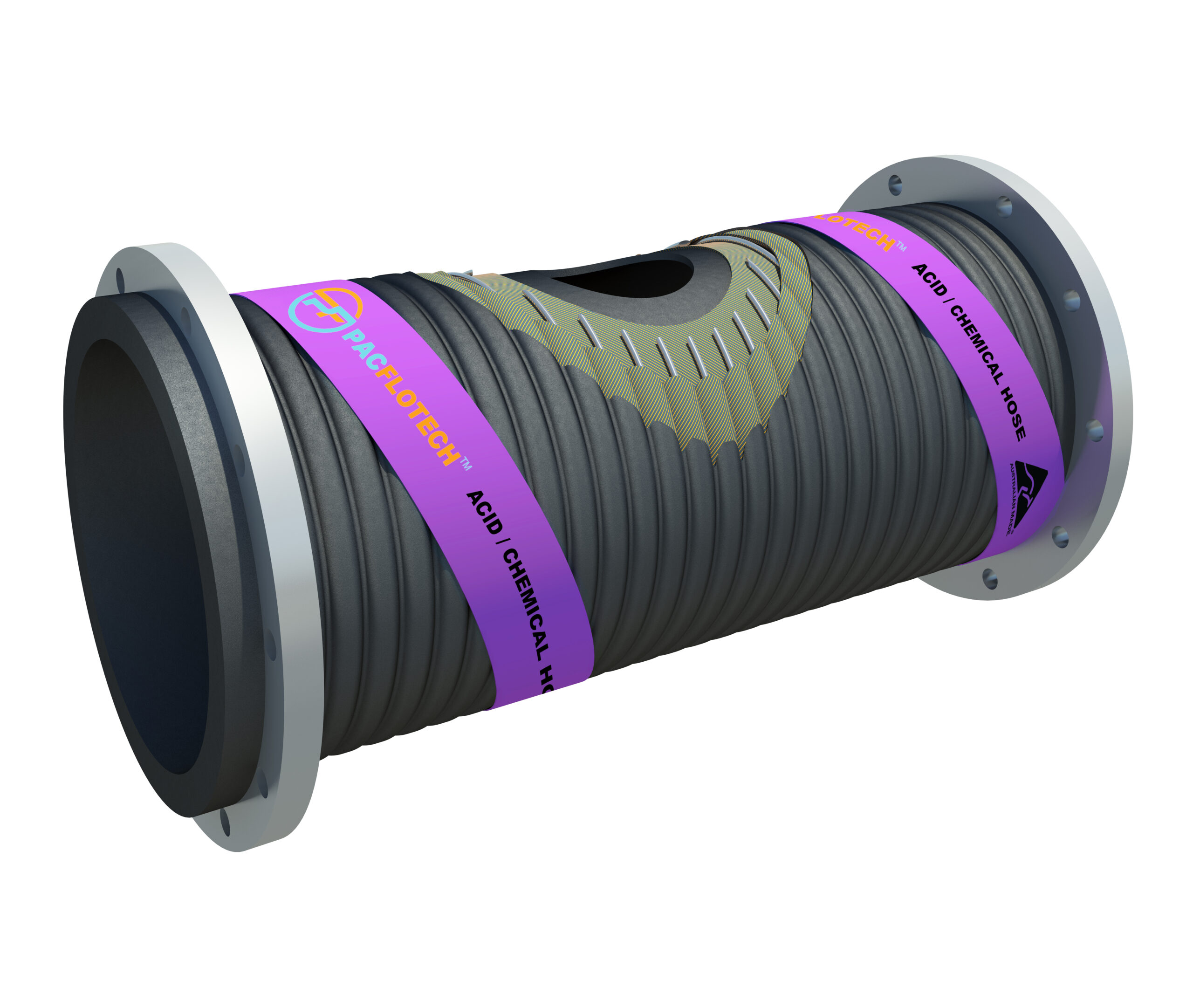

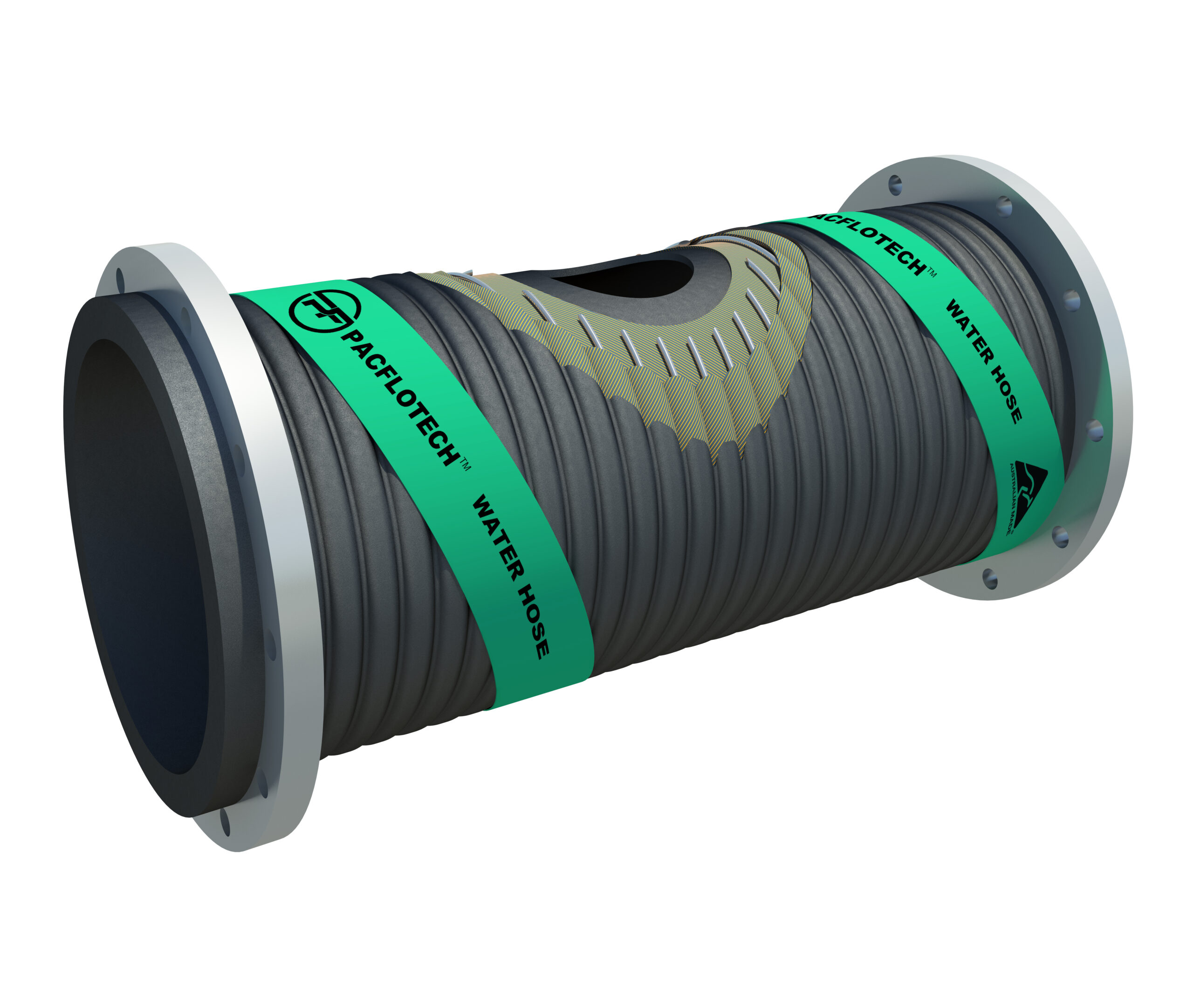

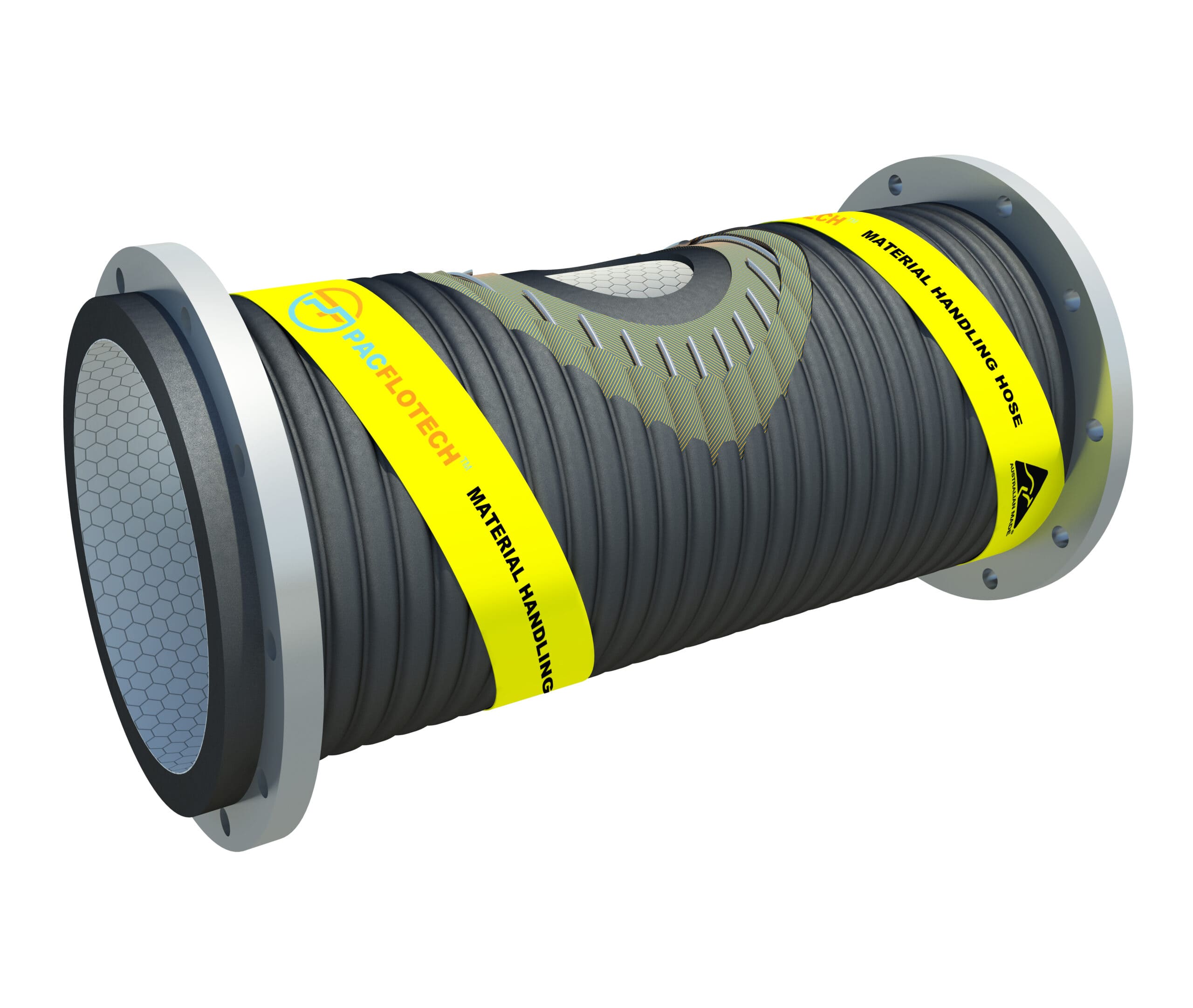

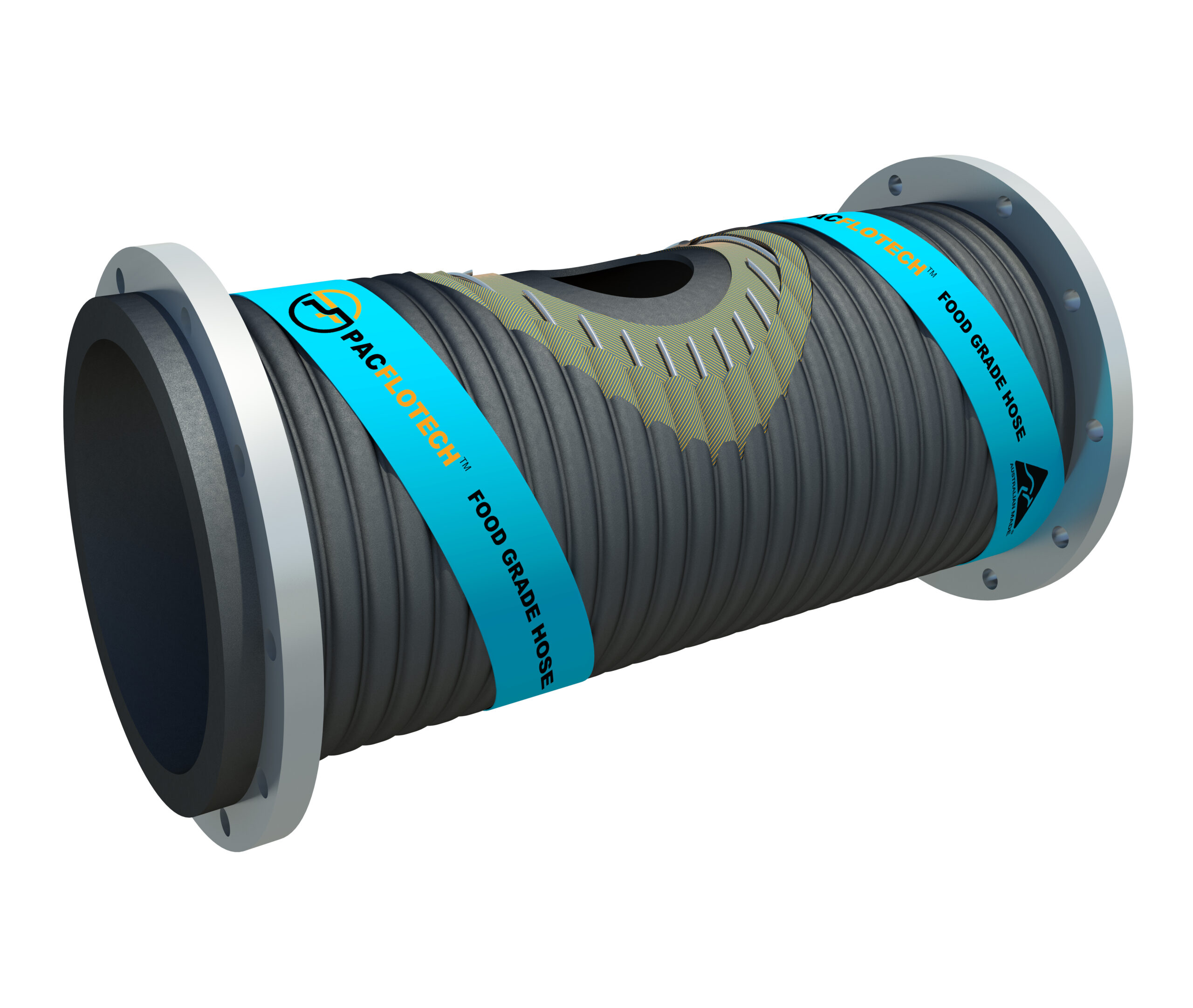

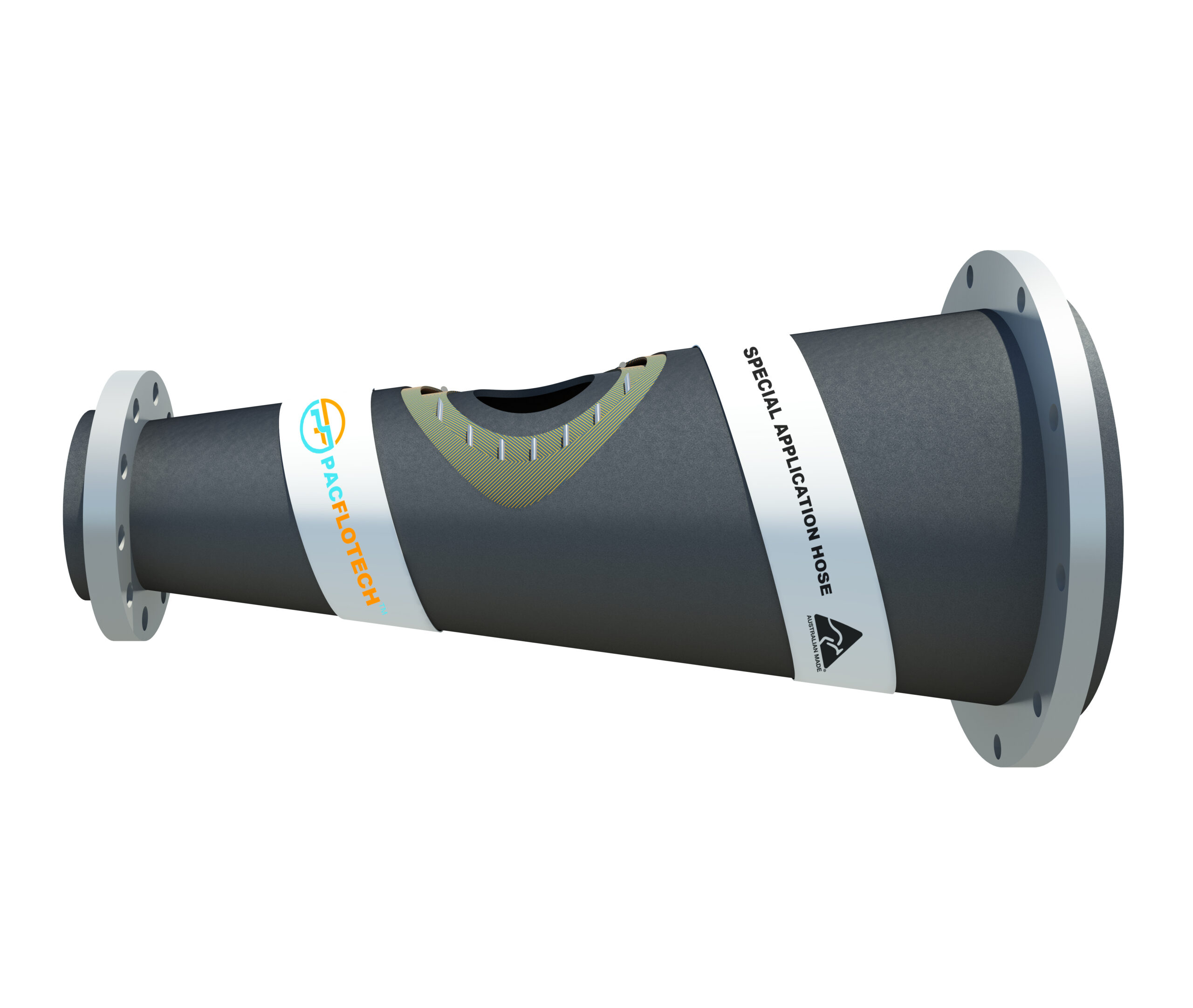

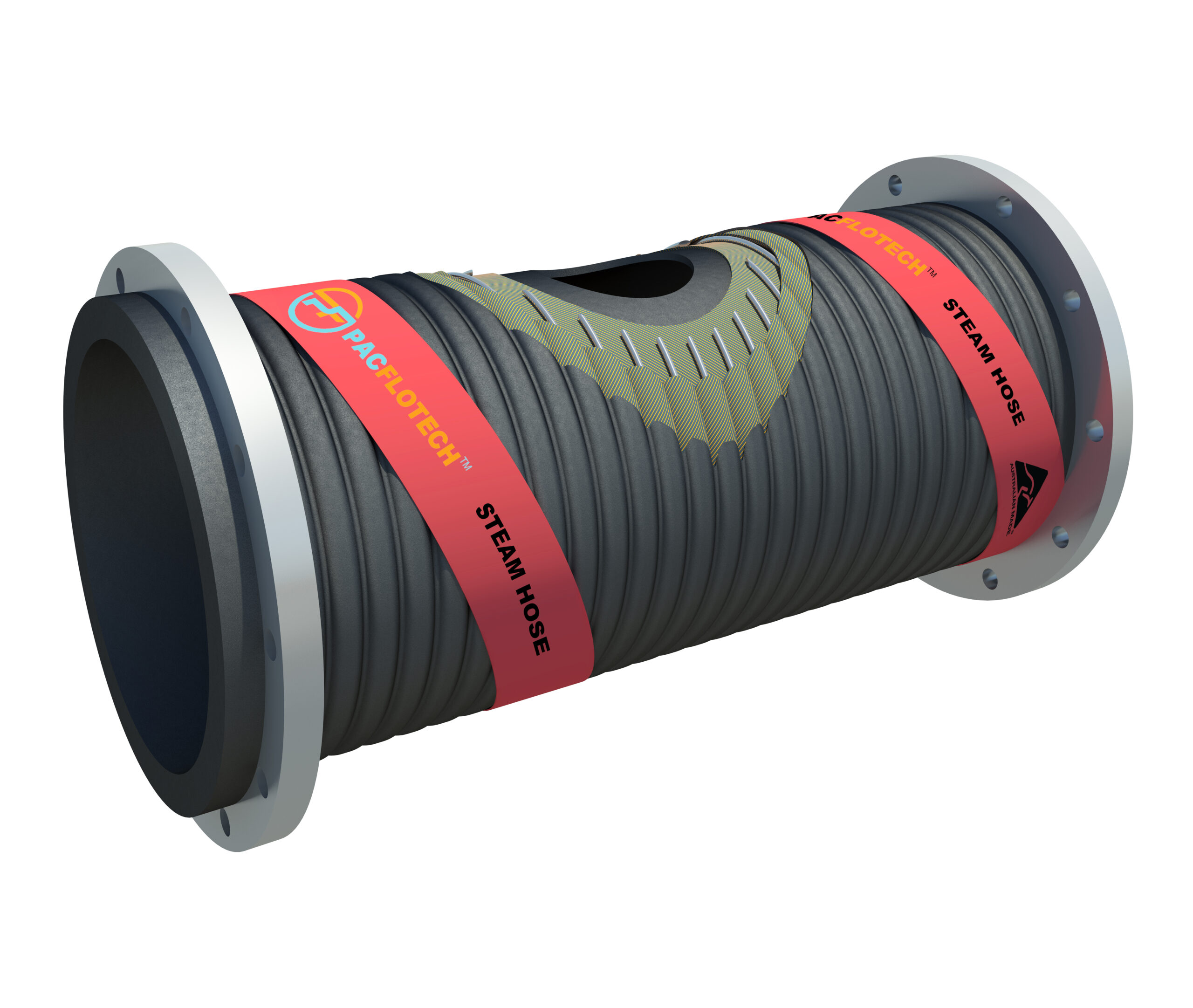

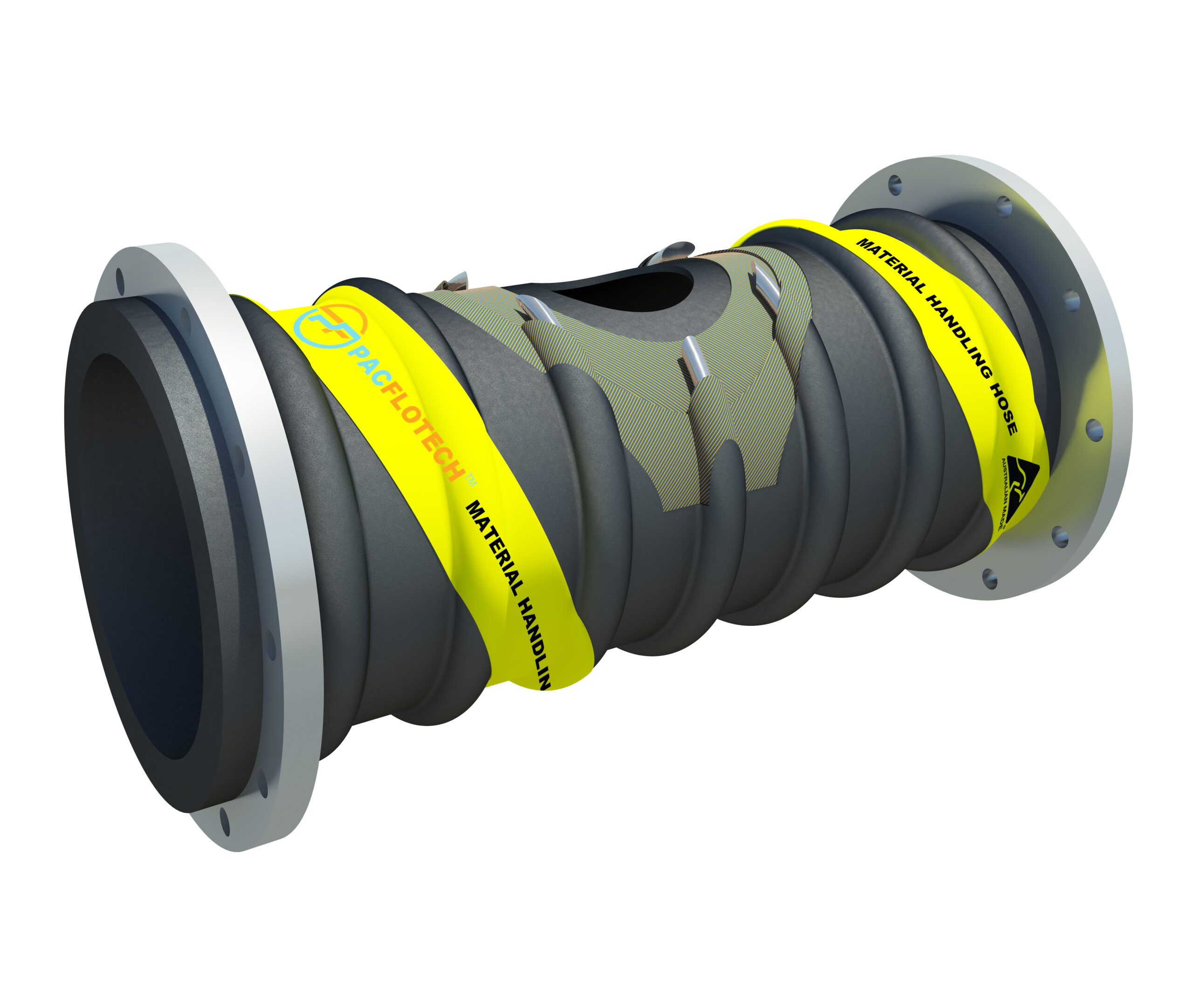

Pacific Flow Technology can provide a pre-formed bends mining hose that combines durability and flexibility. Using the same robust construction as straight-length hoses, our flexible rubber designs allow for adjustments to misalignments while effectively reducing vibration. Each bend is available in a variety of angles and radiuses, allowing for customisation to suit specific applications. We also offer construction using any of our standard rubber compounds to ensure compatibility with the medium being transferred. For areas requiring enhanced wear resistance, we can incorporate alumina ceramic tiles on the outer radius, extending the lifespan of the hose in abrasive environments.

Trusted Expertise in Mining Hoses

Pacific Flow Technology is a trusted name for high-quality hoses in the mining sector. With over 20 years of operation and over 100 years of combined experience, we specialise in crafting durable and reliable hoses tailored to the Australian and global mining industries. Our commitment to quality is evident through our ISO9001-accredited processes, ensuring that every hose leaving our facility meets the highest standards. As one of the largest handmade hose manufacturers in Australia, we’re equipped to handle hoses of any size or complexity, making it easy to get the mining hose with bend you need.