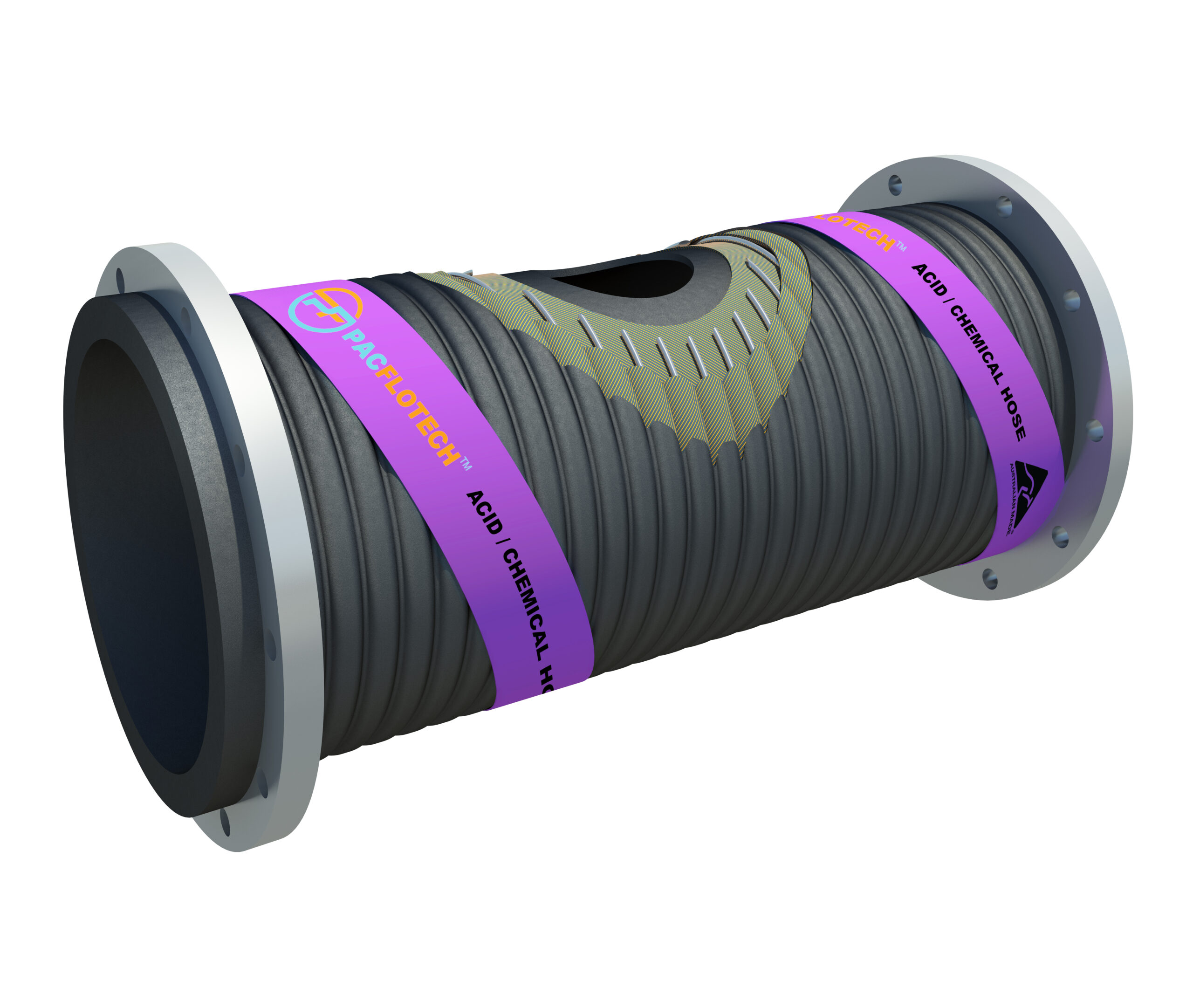

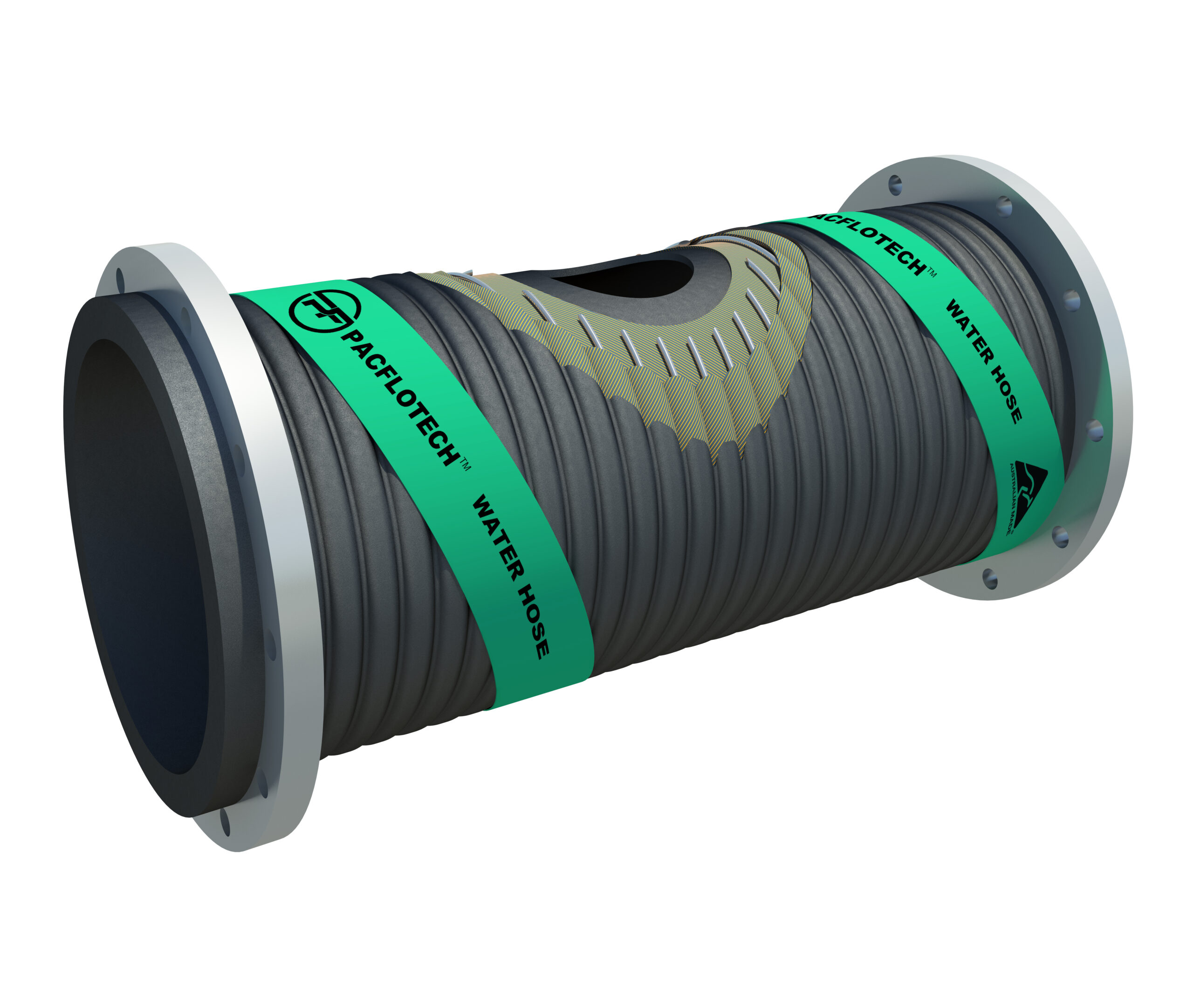

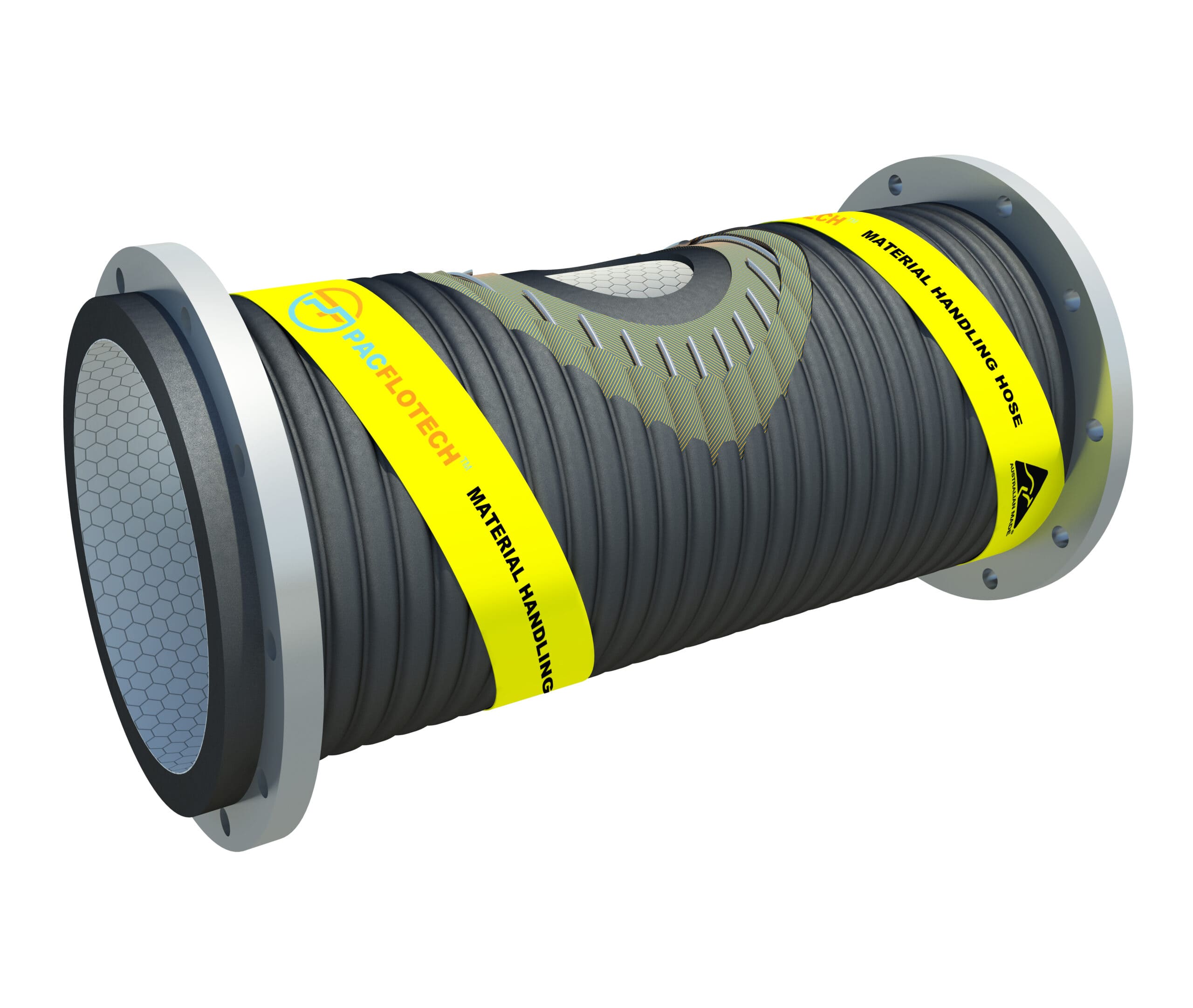

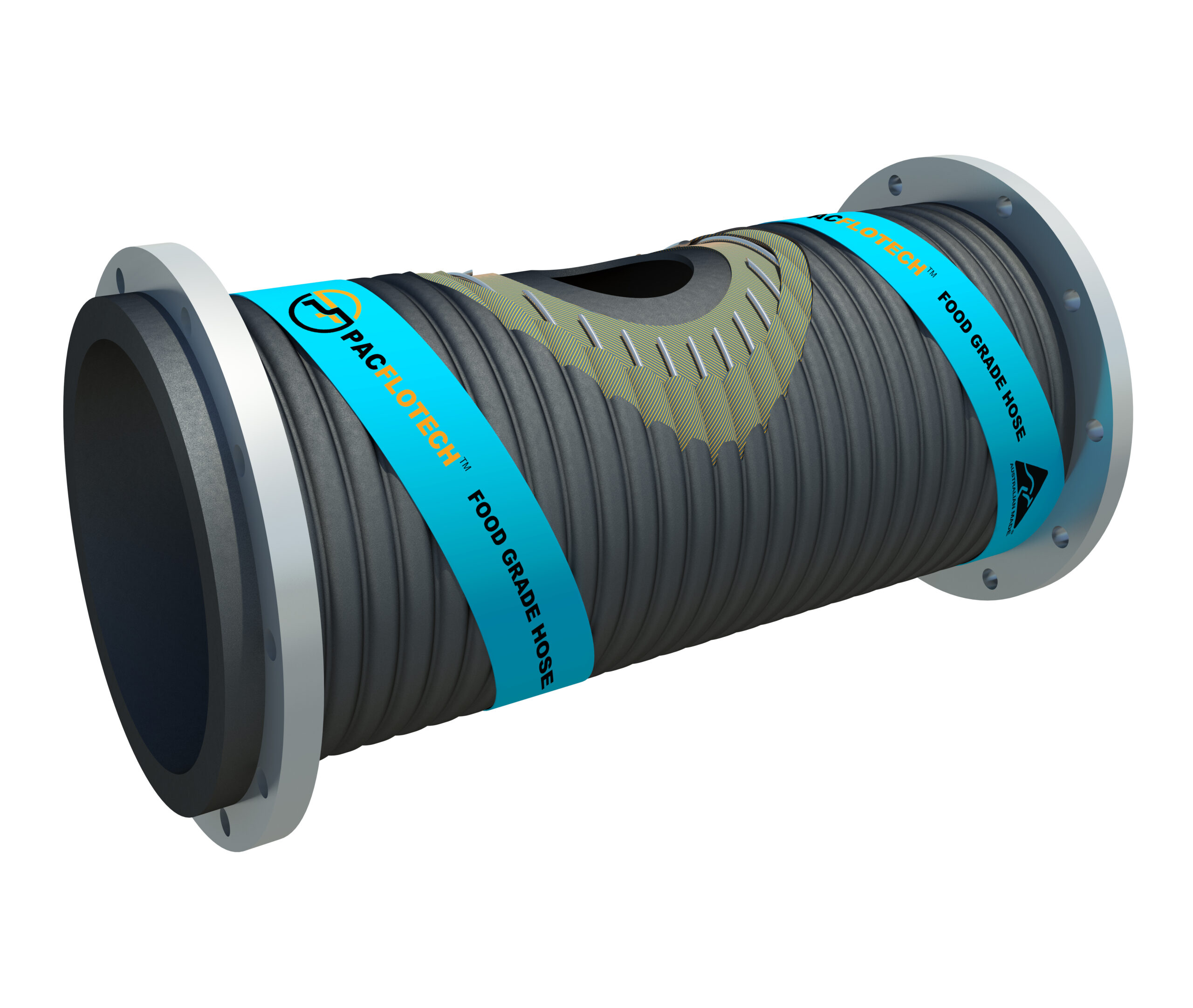

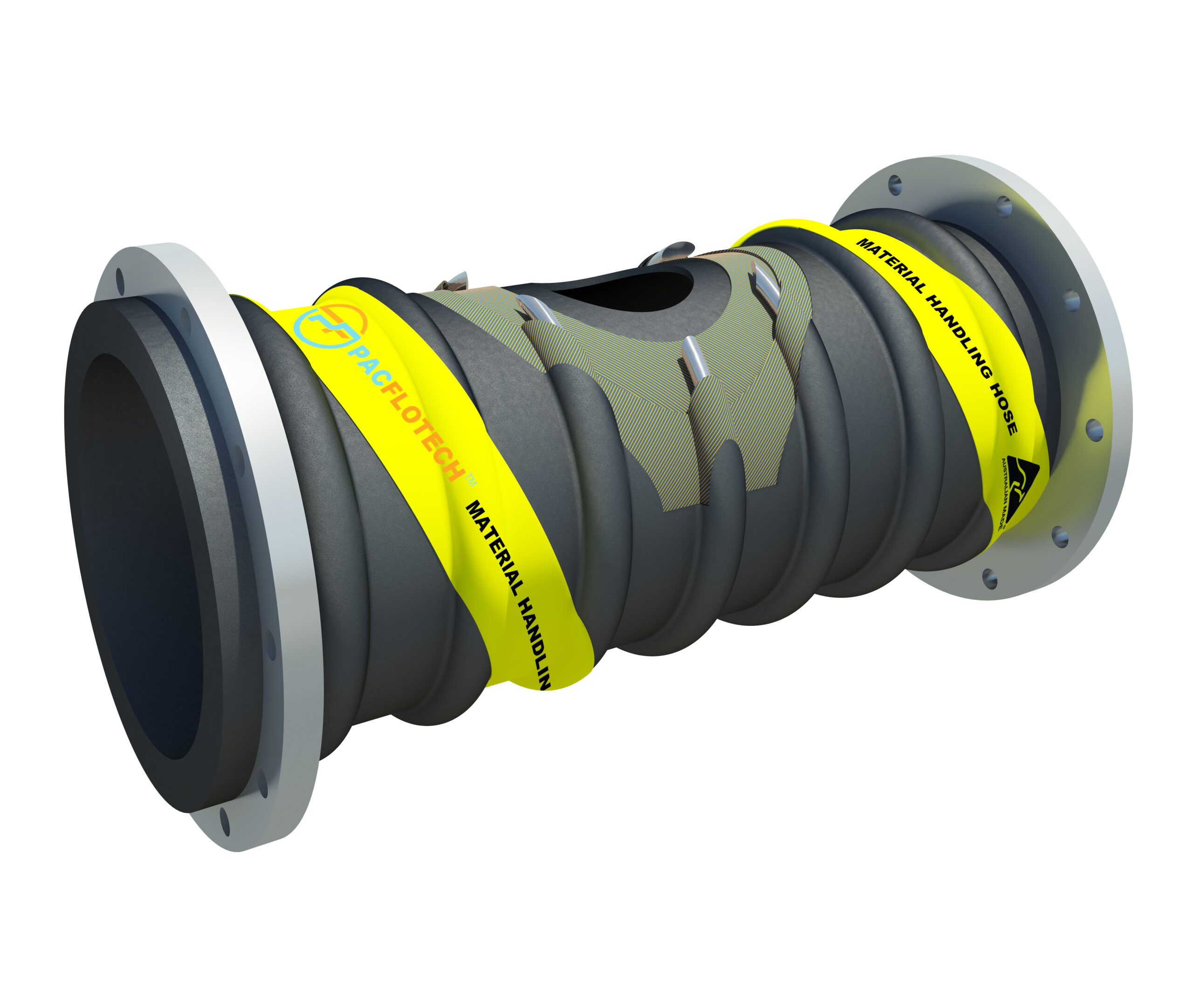

Turboflex Hose

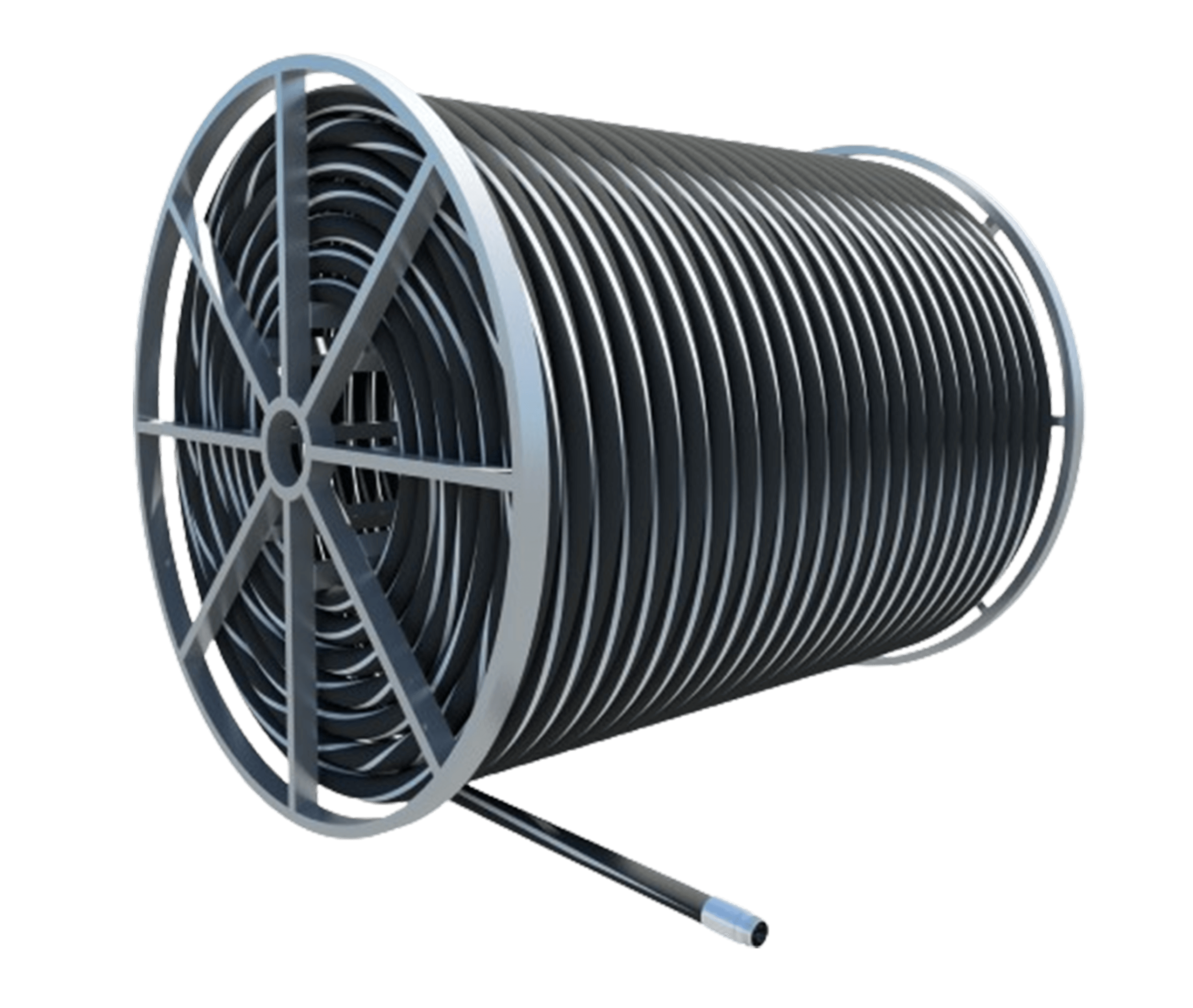

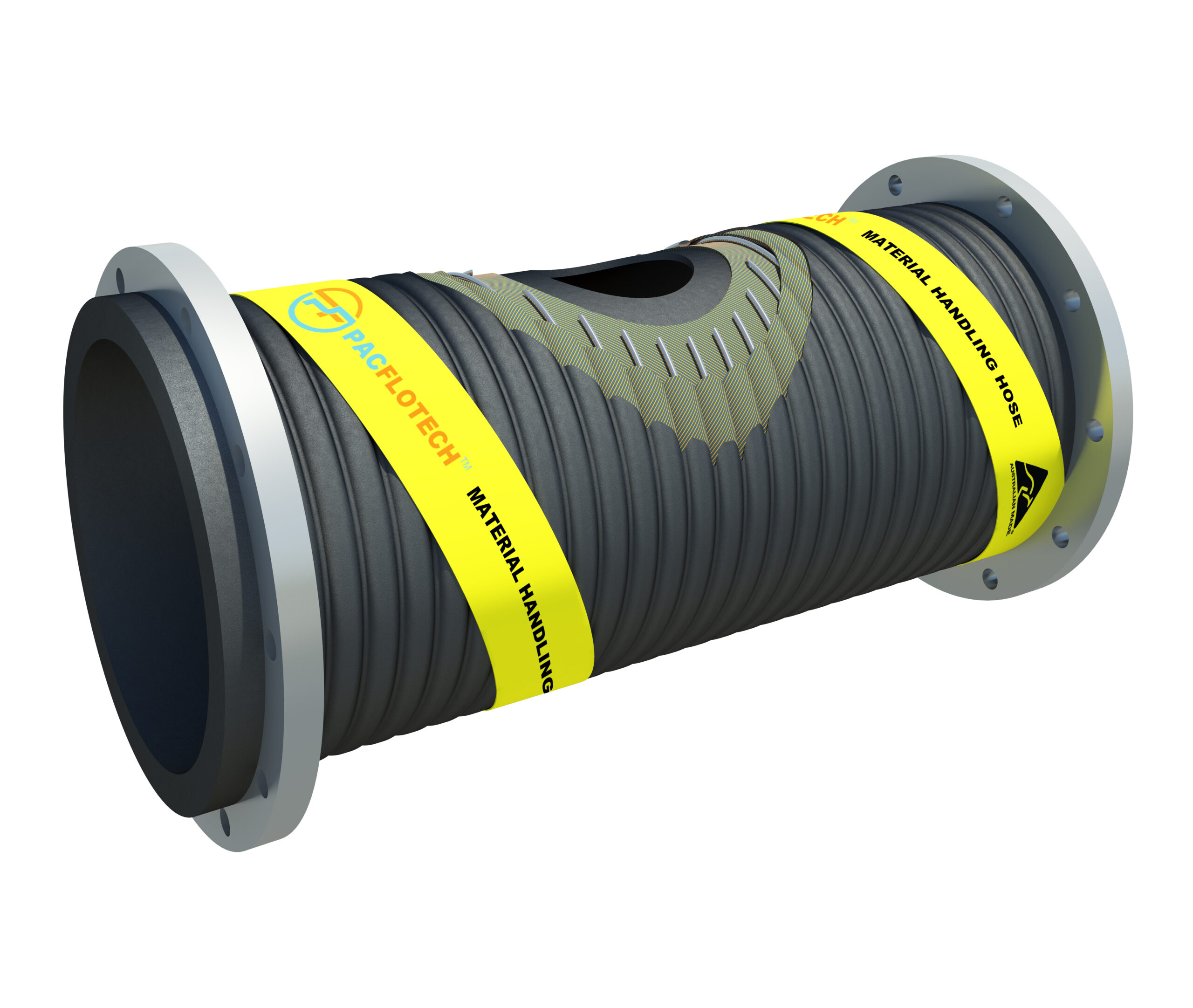

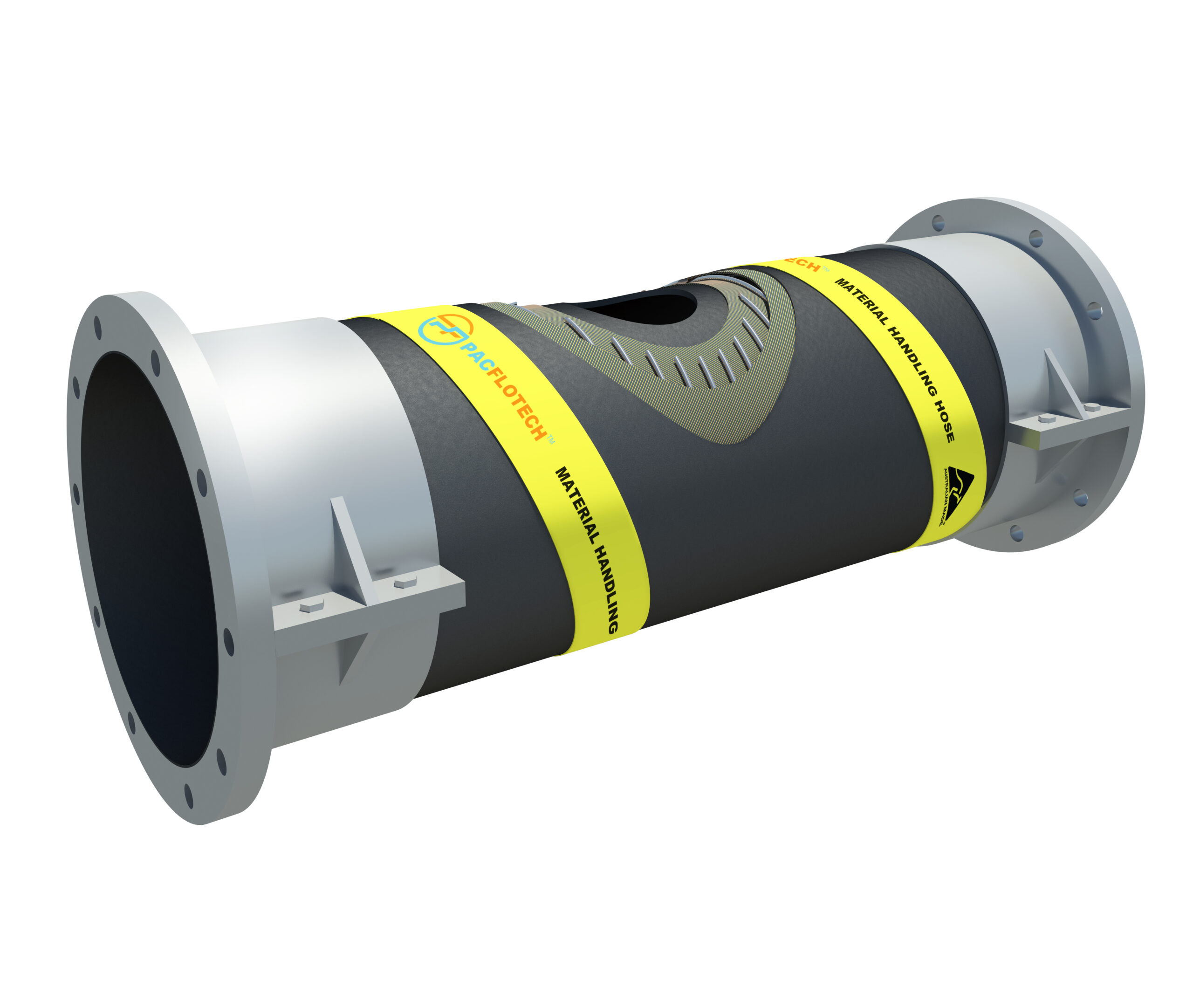

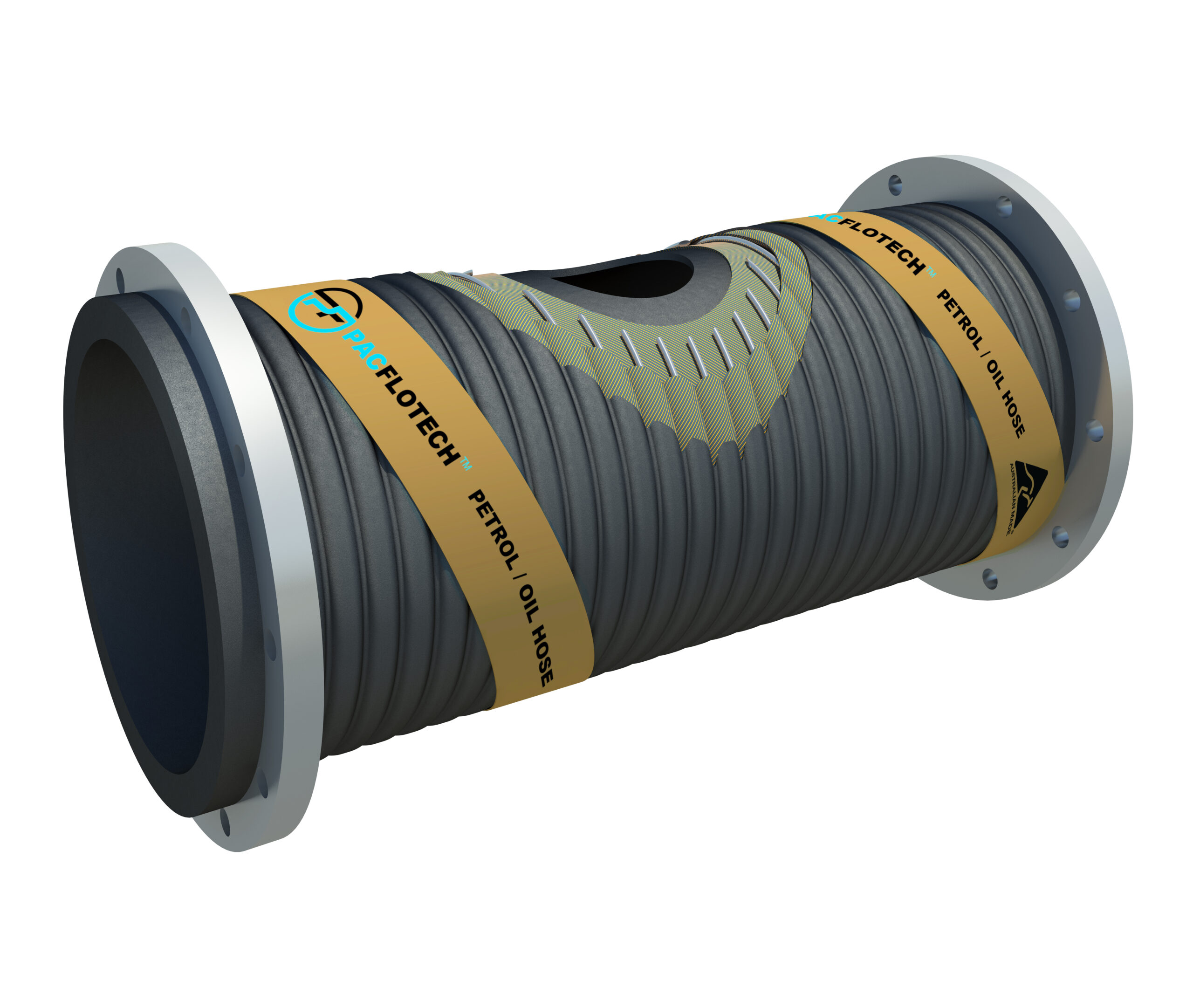

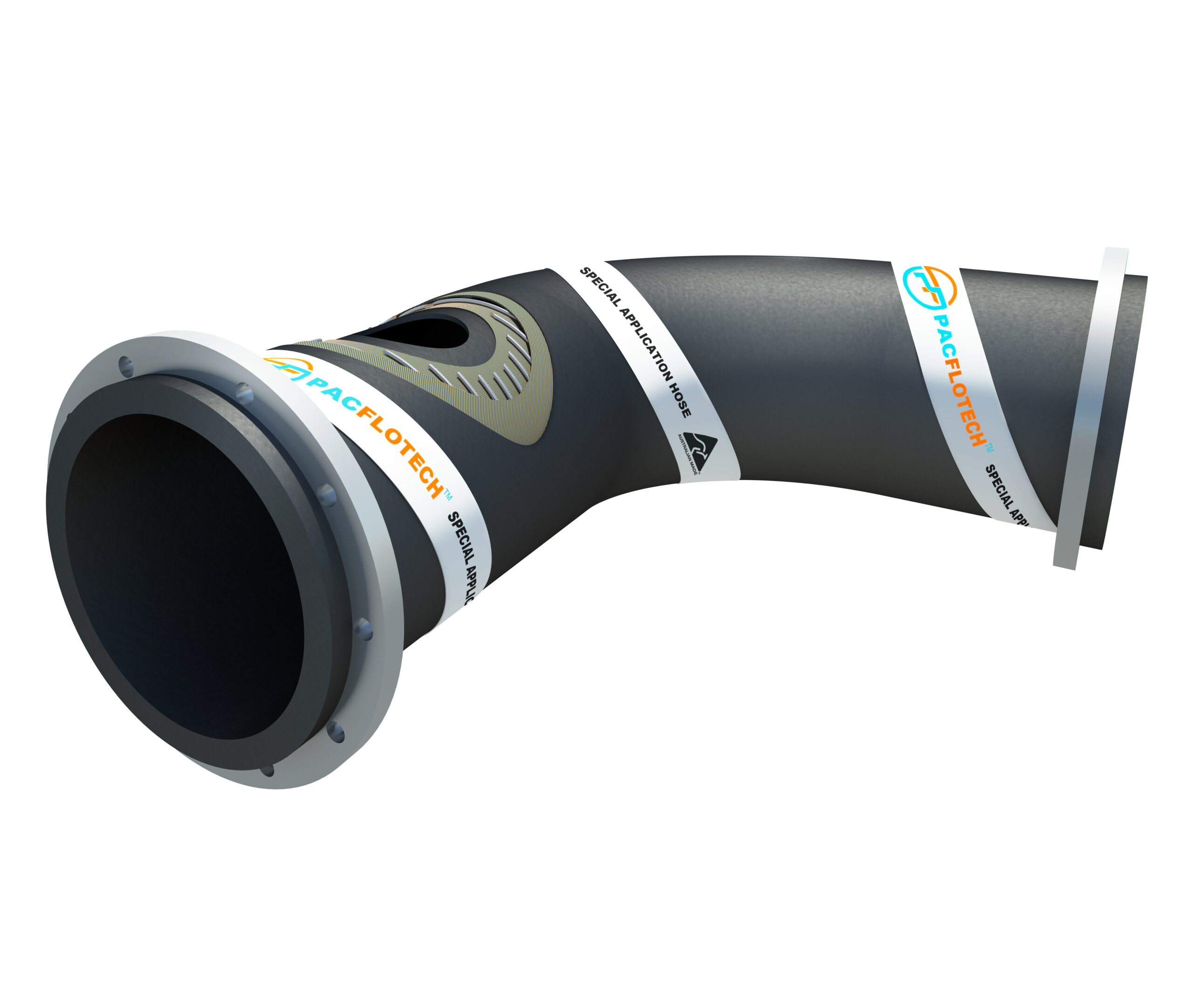

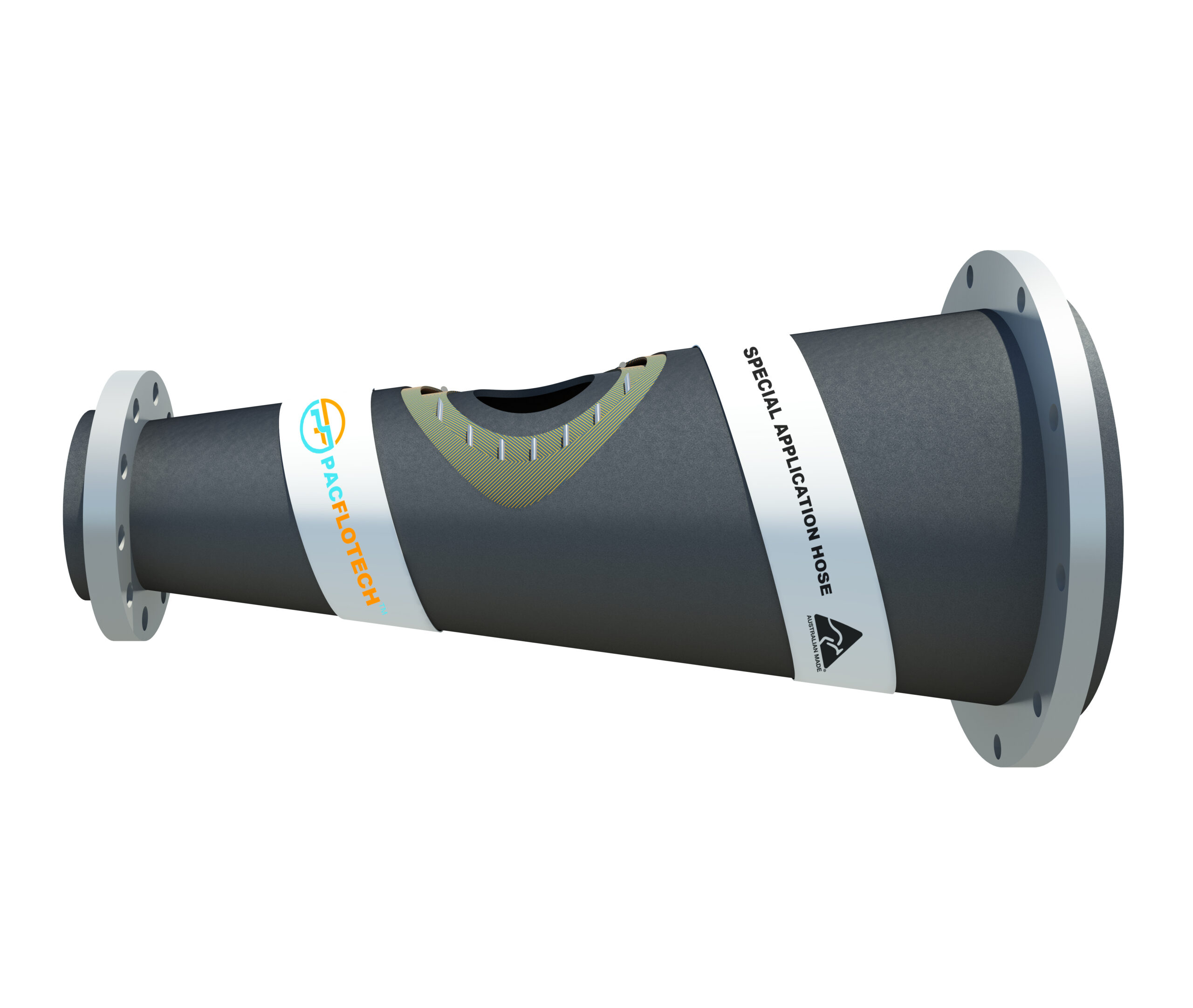

Specially designed to maximise hose flexibility where tight bend radius are paramount, Pacific Flow Technology’s Turboflex mining hose offers superior performance in challenging applications where space is limited.

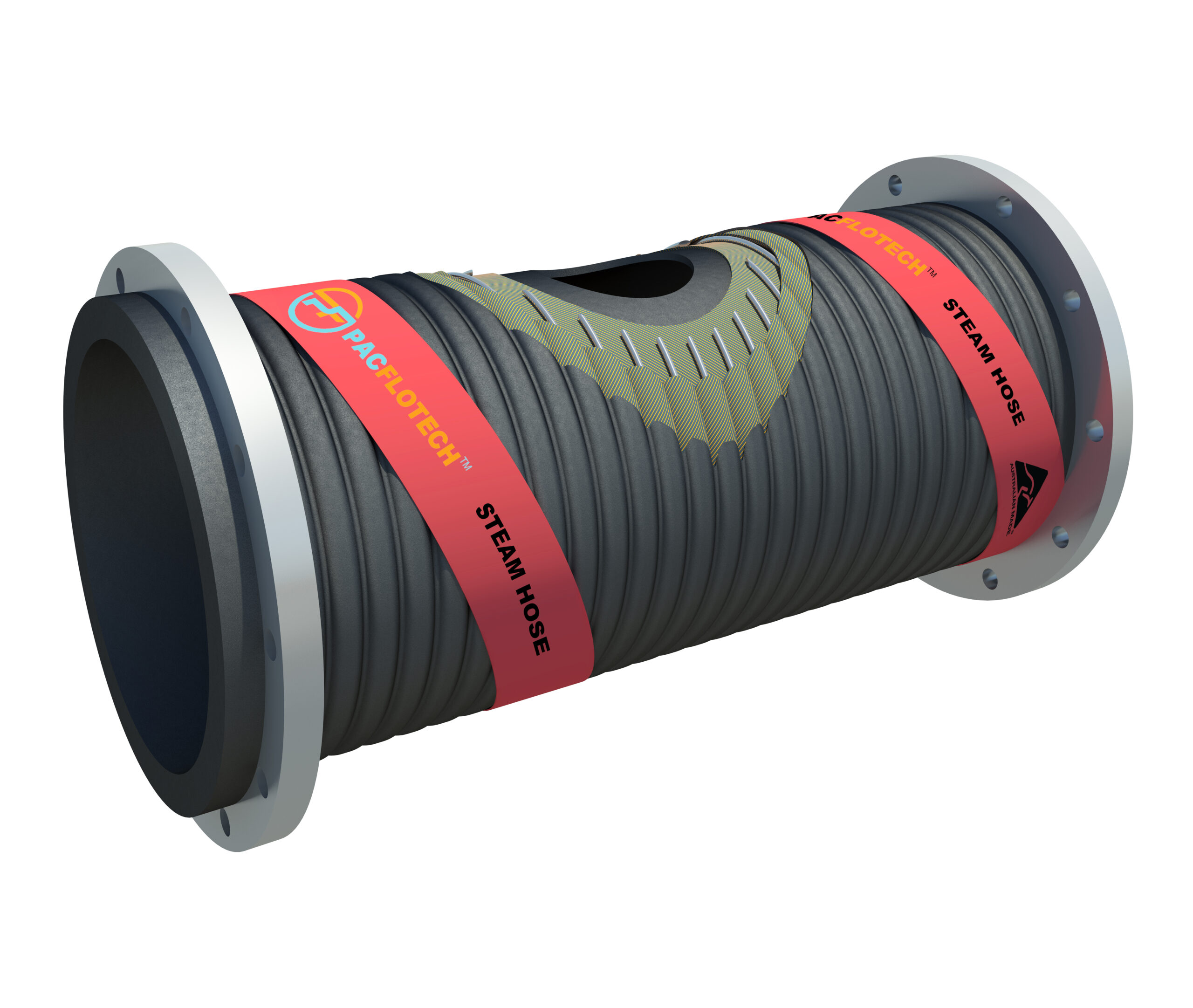

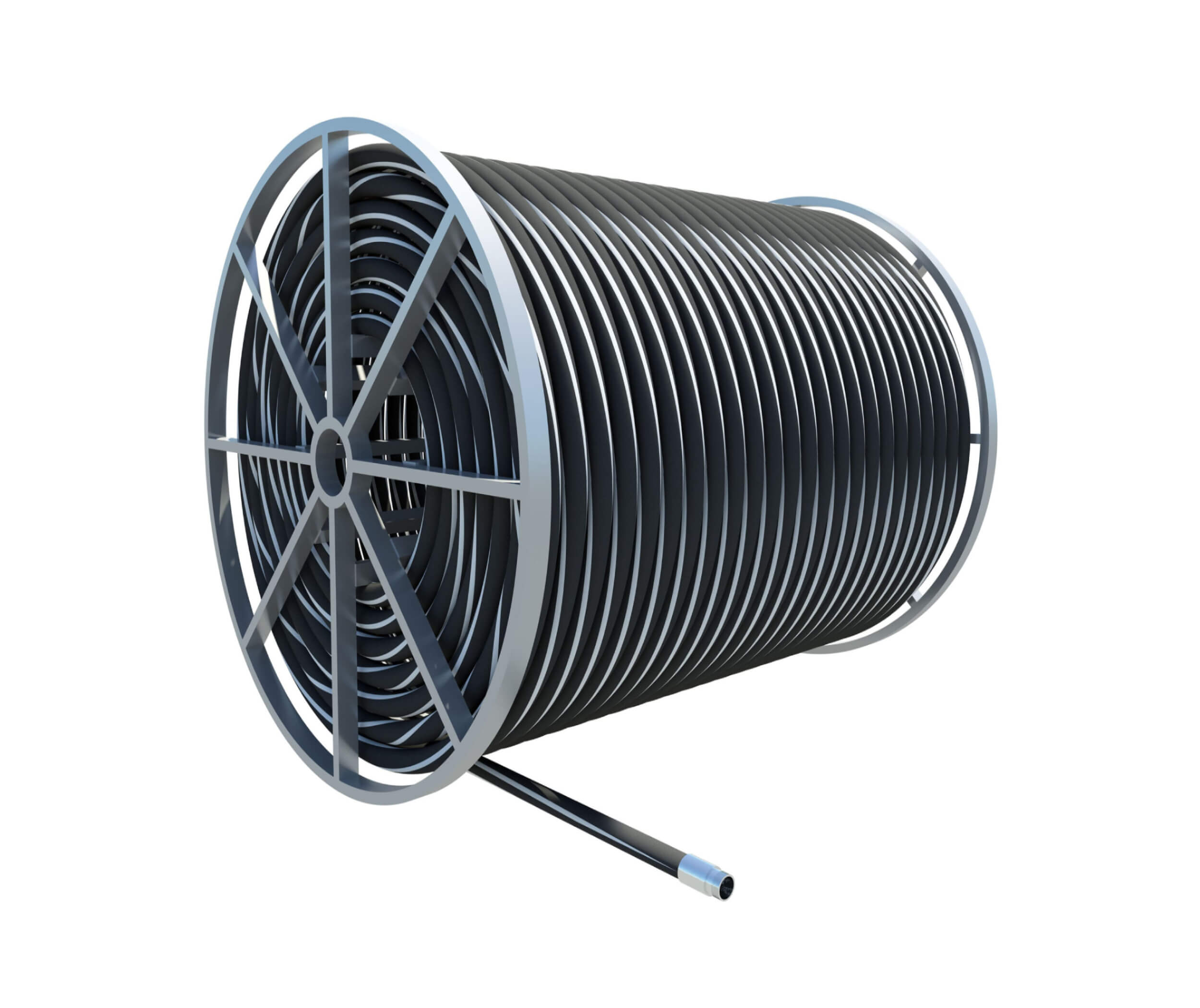

Delivering reliability and durability even in the harshest environments, the unmatched flexibility of our Turboflex hose makes it ideal for use in industries that require tight-radius piping solutions without compromising on performance or safety. Using unique hose construction exclusively designed and tested by Pacific Flow Technology, we are able to achieve one of the most flexible mining hoses available on the market. Our Turboflex design has been tested to achieve an impressive 2D bend radius without kinking, which means they can bend to a diameter twice the size of the hose itself, offering unparalleled versatility in confined spaces. Please refer to our datasheets for more technical info on pressure ratings, bend radius and available sizes.

Why Choose Us for Turboflex Hose?

When it comes to flexible mining hose supplies, Pacific Flow Technology stands out as a trusted Turboflex hose supplier. With over 20 years of operational excellence and a combined 100 years of industry expertise, we have the capability to deliver hoses that meet your exact specifications. Our state-of-the-art facility, one of the largest in Australia, allows us to manufacture Turboflex hose tailored to your specific requirements, no matter the size or complexity. We follow stringent quality control measures under our ISO9001-accredited system, ensuring every Turboflex hose is of the highest standard. Whether you need a Turboflex water hose or a Turboflex hose for extreme temperatures or high pressures, we can provide the perfect solution.