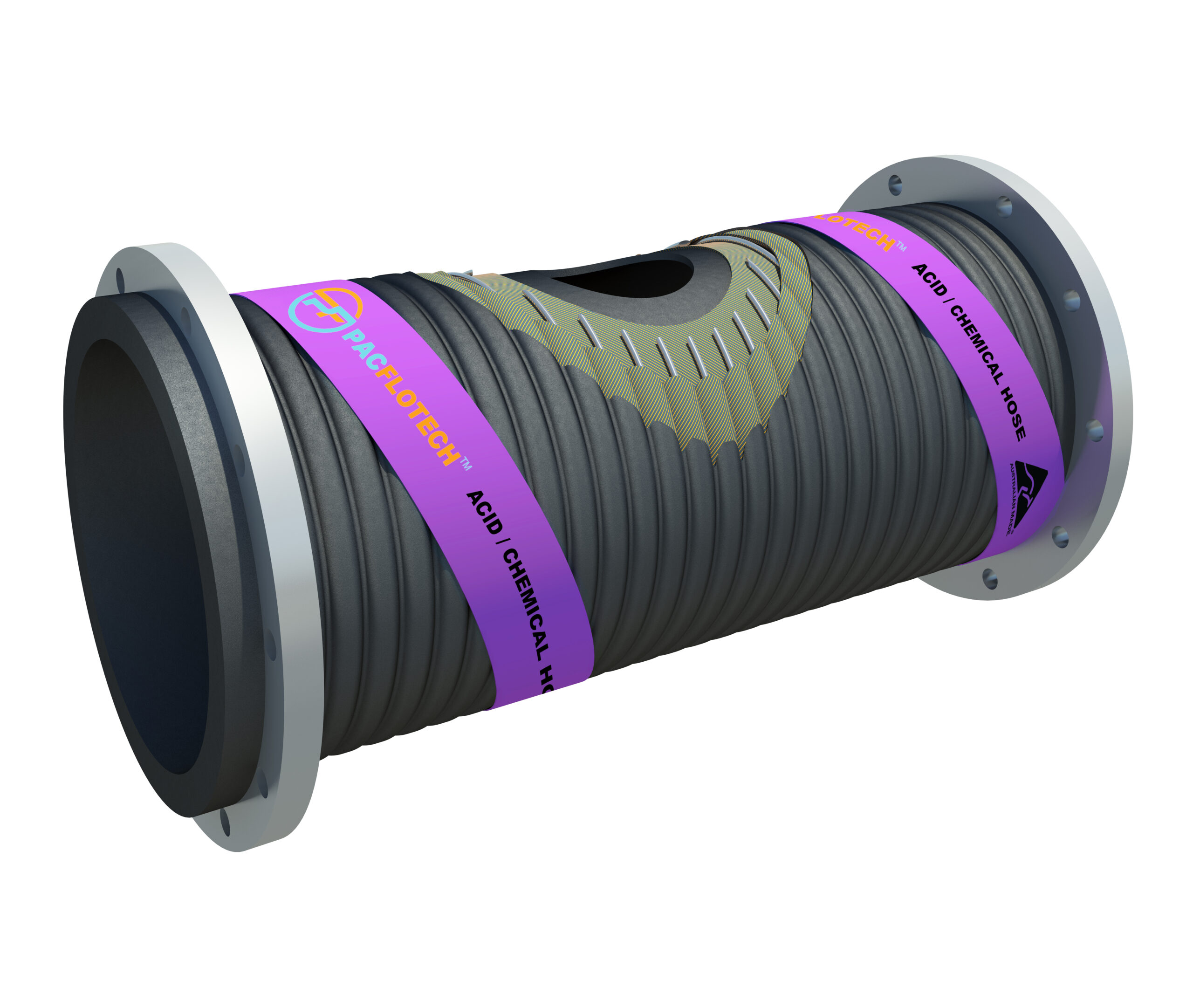

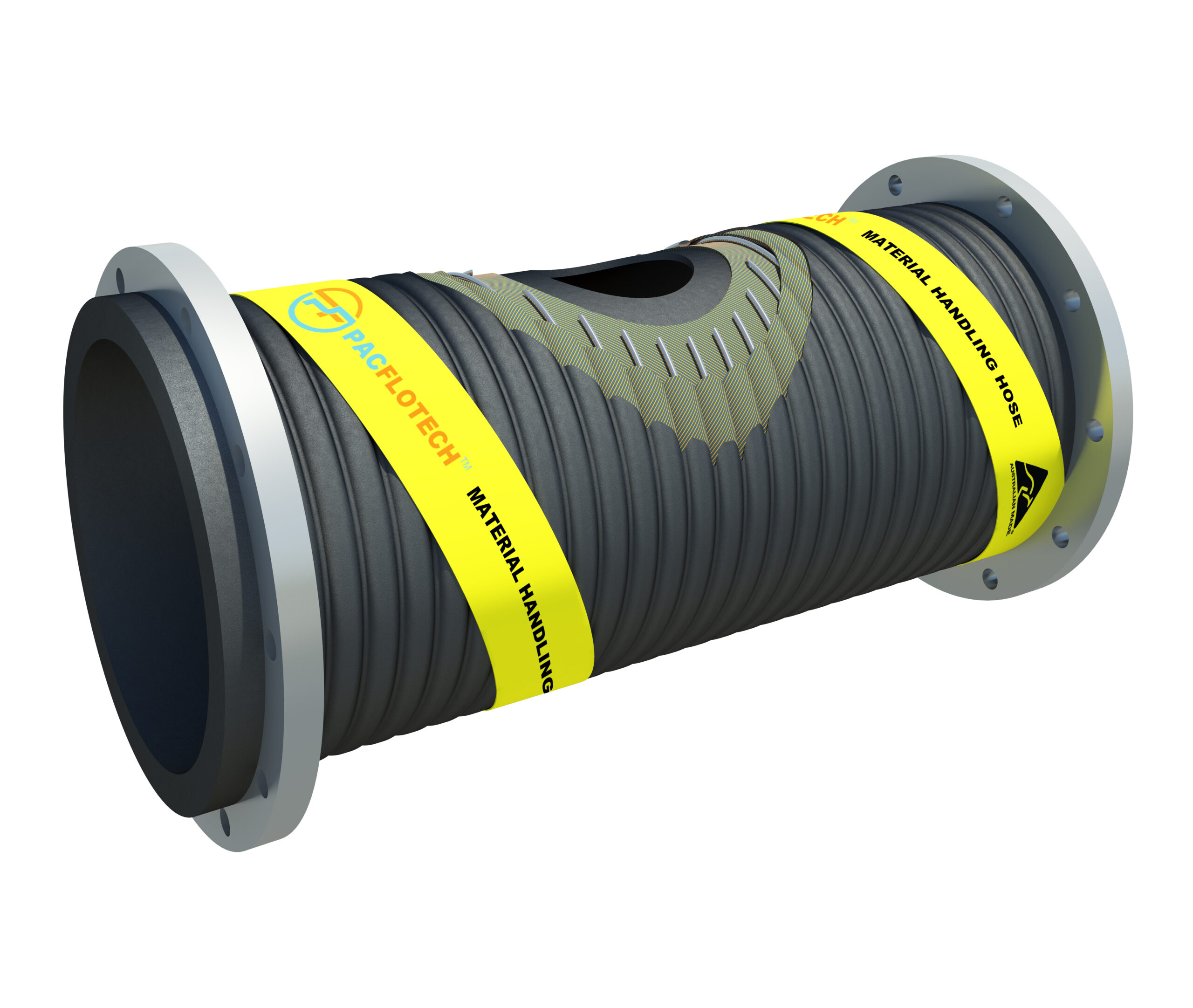

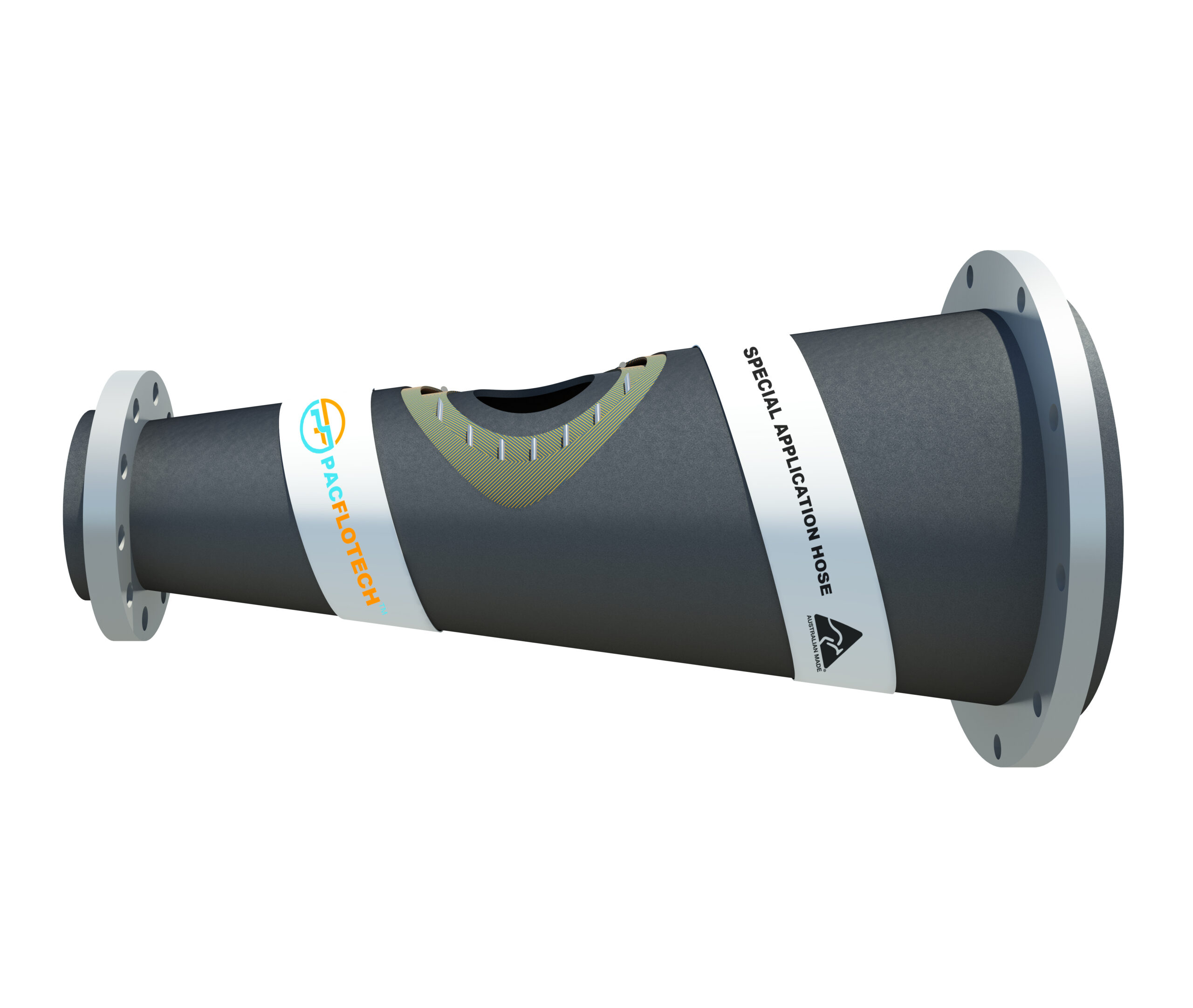

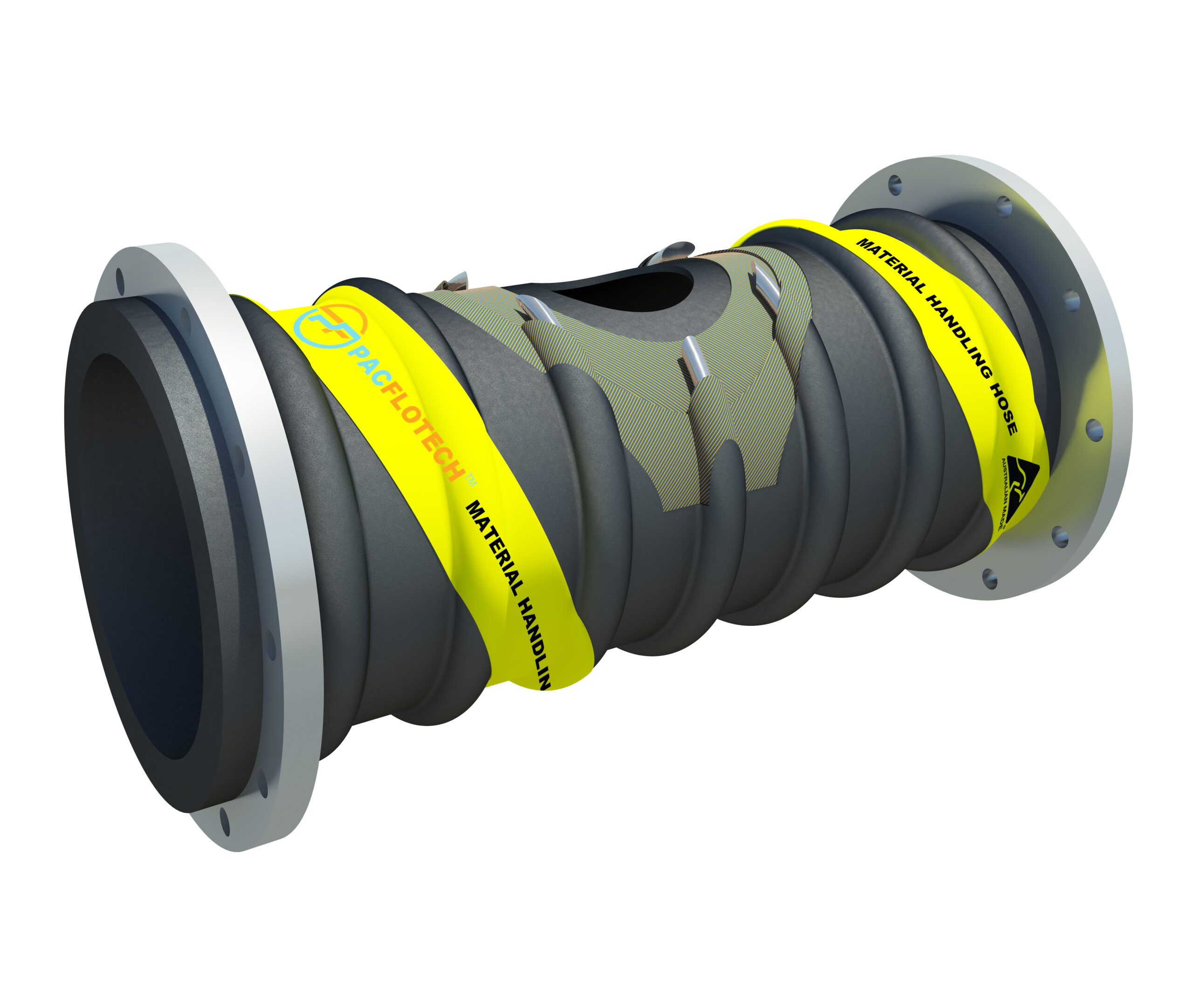

Ceramic Lined Rubber Hose Ceramic Lined

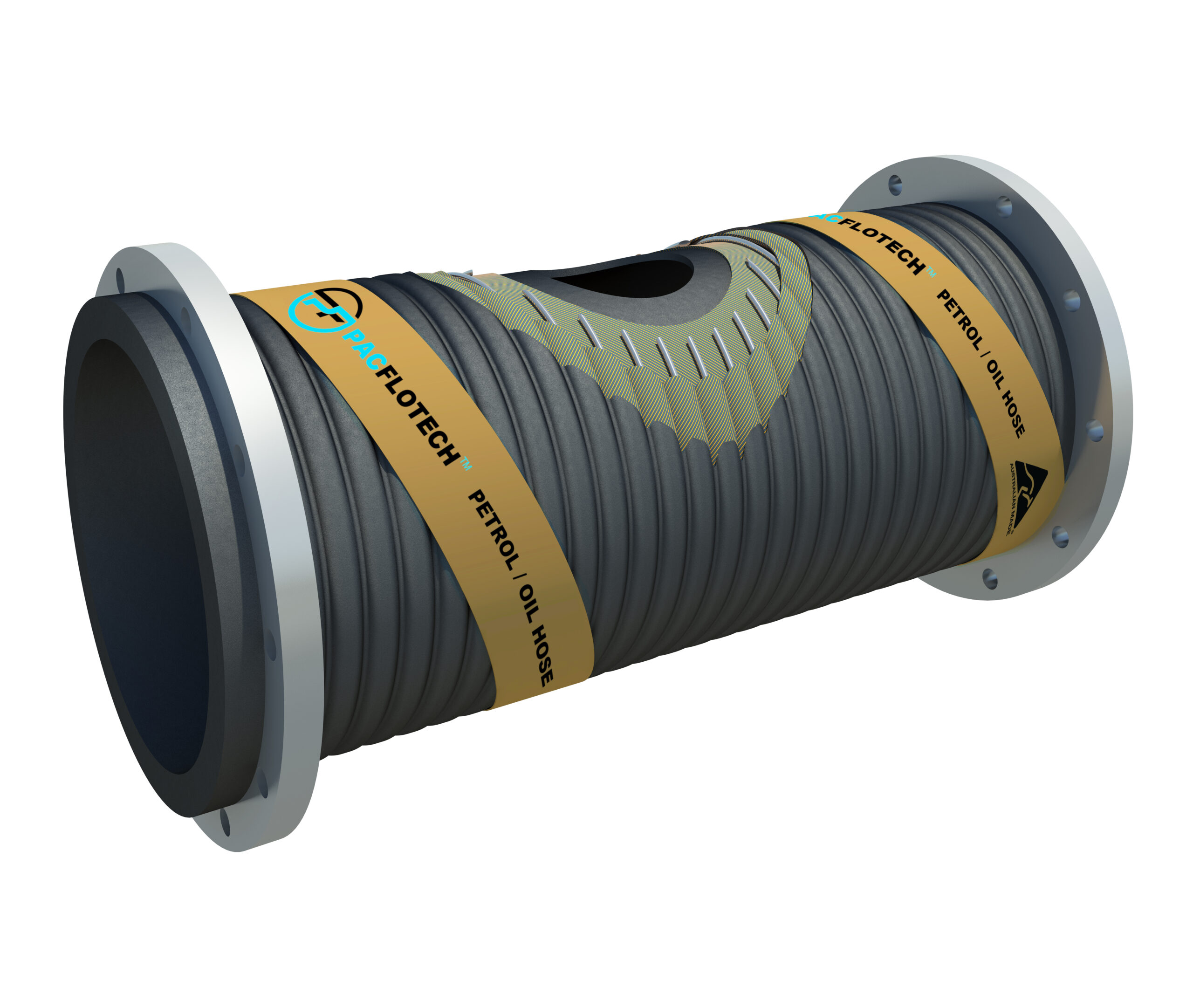

Our ceramic lined rubber hose is made with rubber-filled and backed ceramic tiles, helping to maintain flexibility and allow for movement and misalignment during operation. This design also ensures maximum adhesion of the tiles to the hose body, significantly reducing the risk of delamination. As trusted ceramic lined hose manufacturers, you can rely on us to provide solutions that meet your specific requirements. Our ceramic lined hose products are designed for optimal performance, making them ideal for handling abrasive materials in mining.

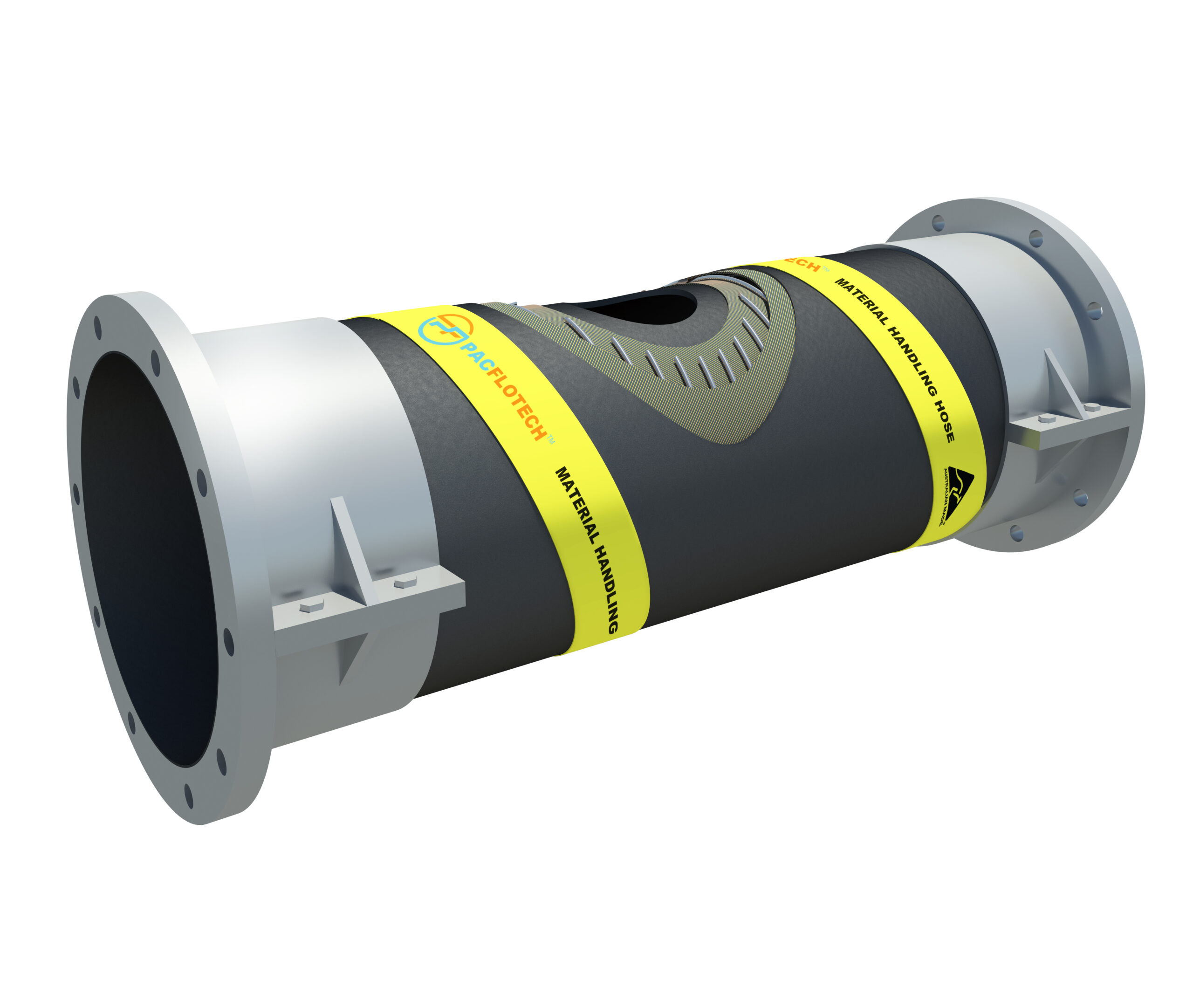

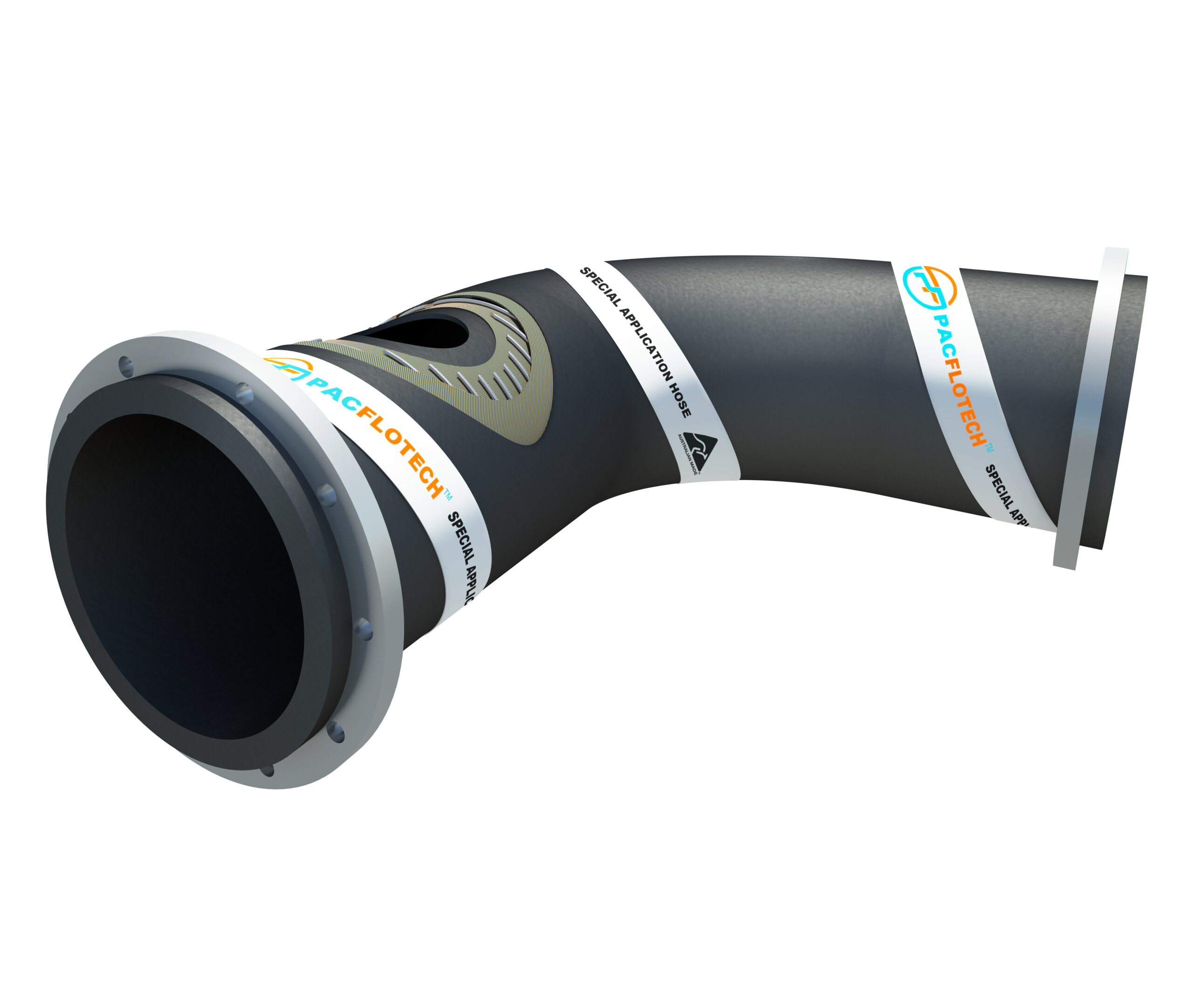

Customised Ceramic Hose Solutions

Our ceramic hose products come standard with full ceramic tile coverage, ensuring high abrasion resistance across the hose’s surface. We additionally offer customisation options to meet unique demands. For instance, we can provide ceramic coverage only on the outer radius of a pre-formed bend, where abrasion resistance needs to be greater. This customisation flexibility allows us to reduce costs, whilst also increasing longevity in critical areas. With over 100 years of combined experience, you can rely on our experts to provide ceramic lined hoses that deliver lasting reliability in the most rigorous environments.