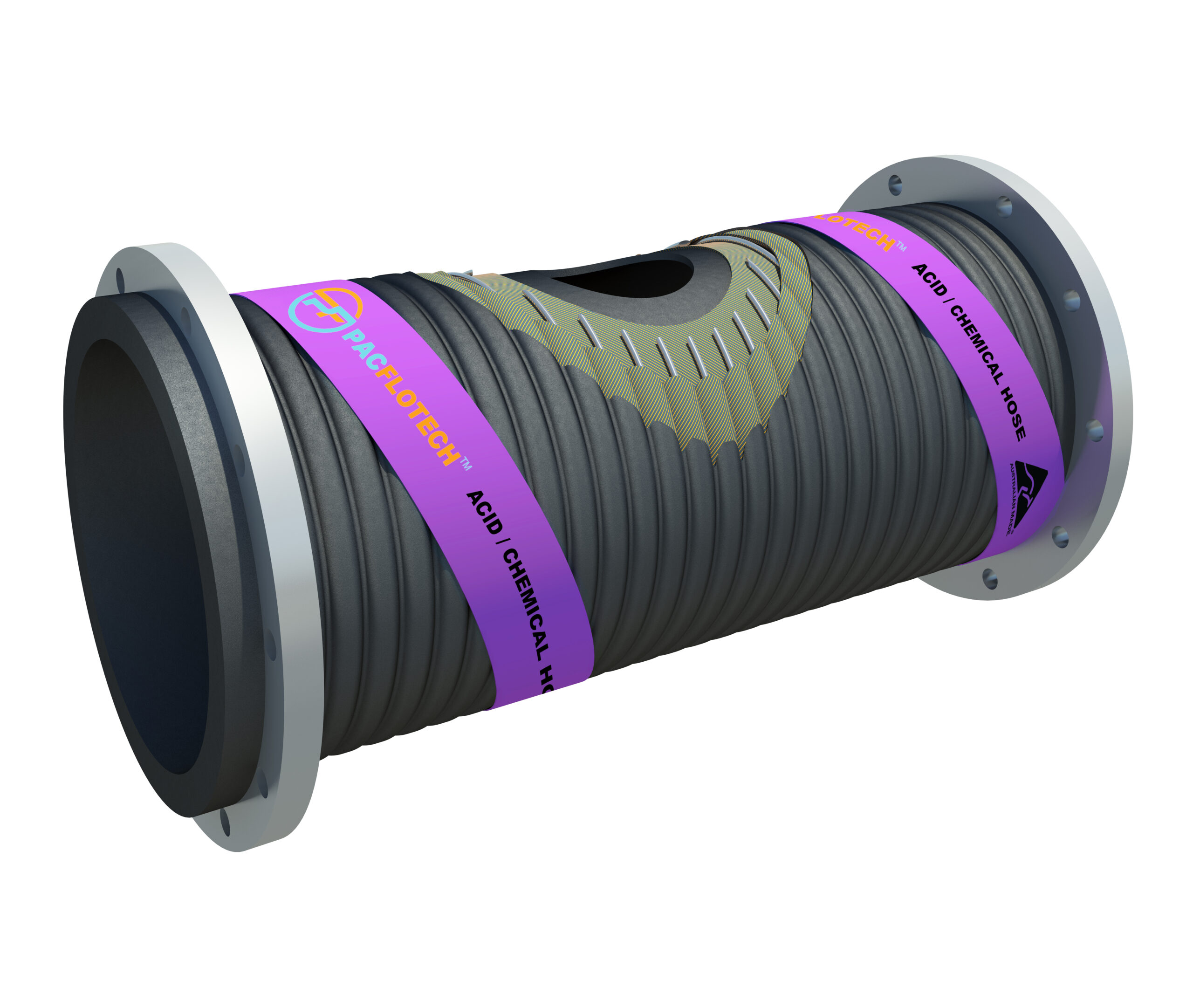

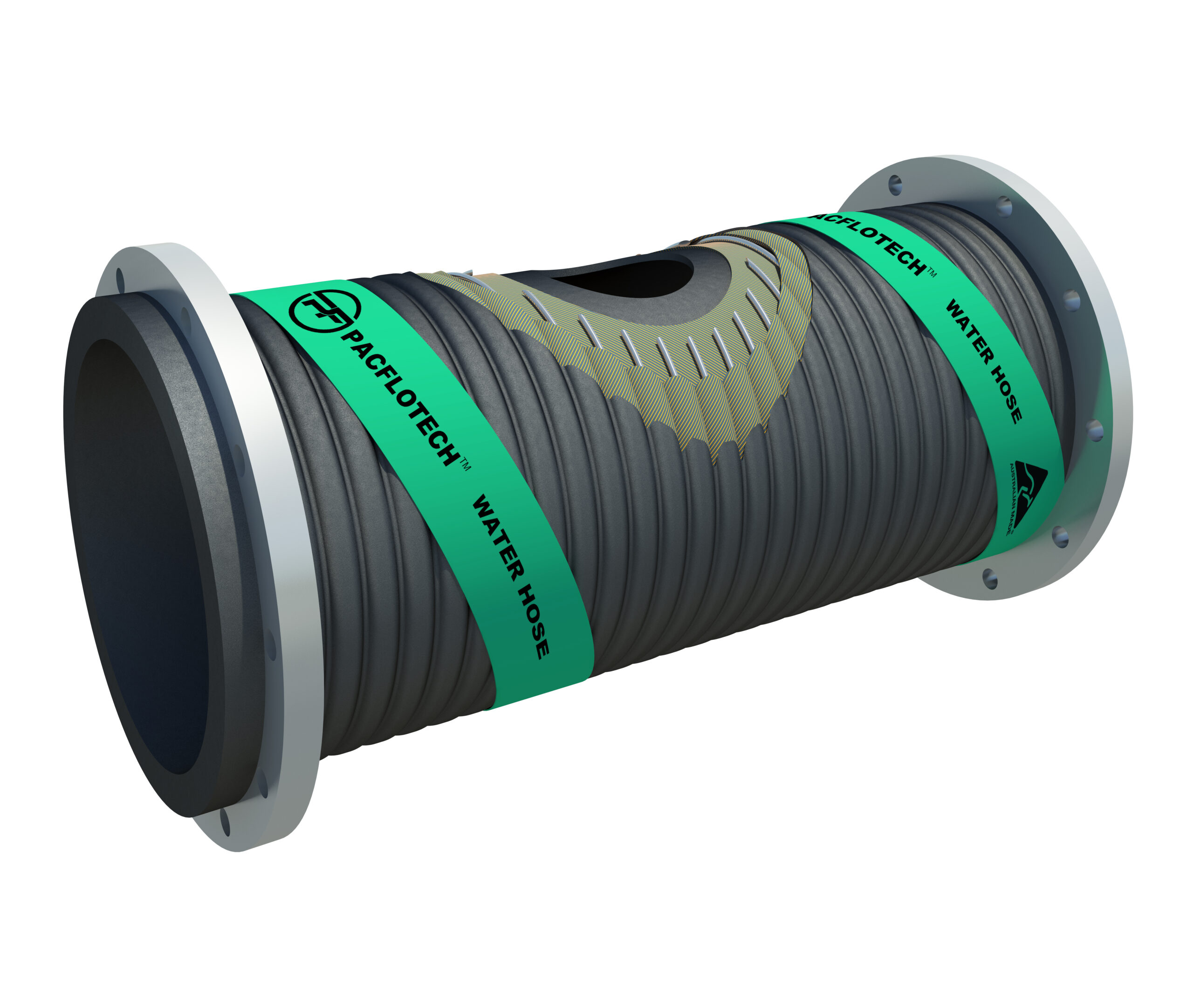

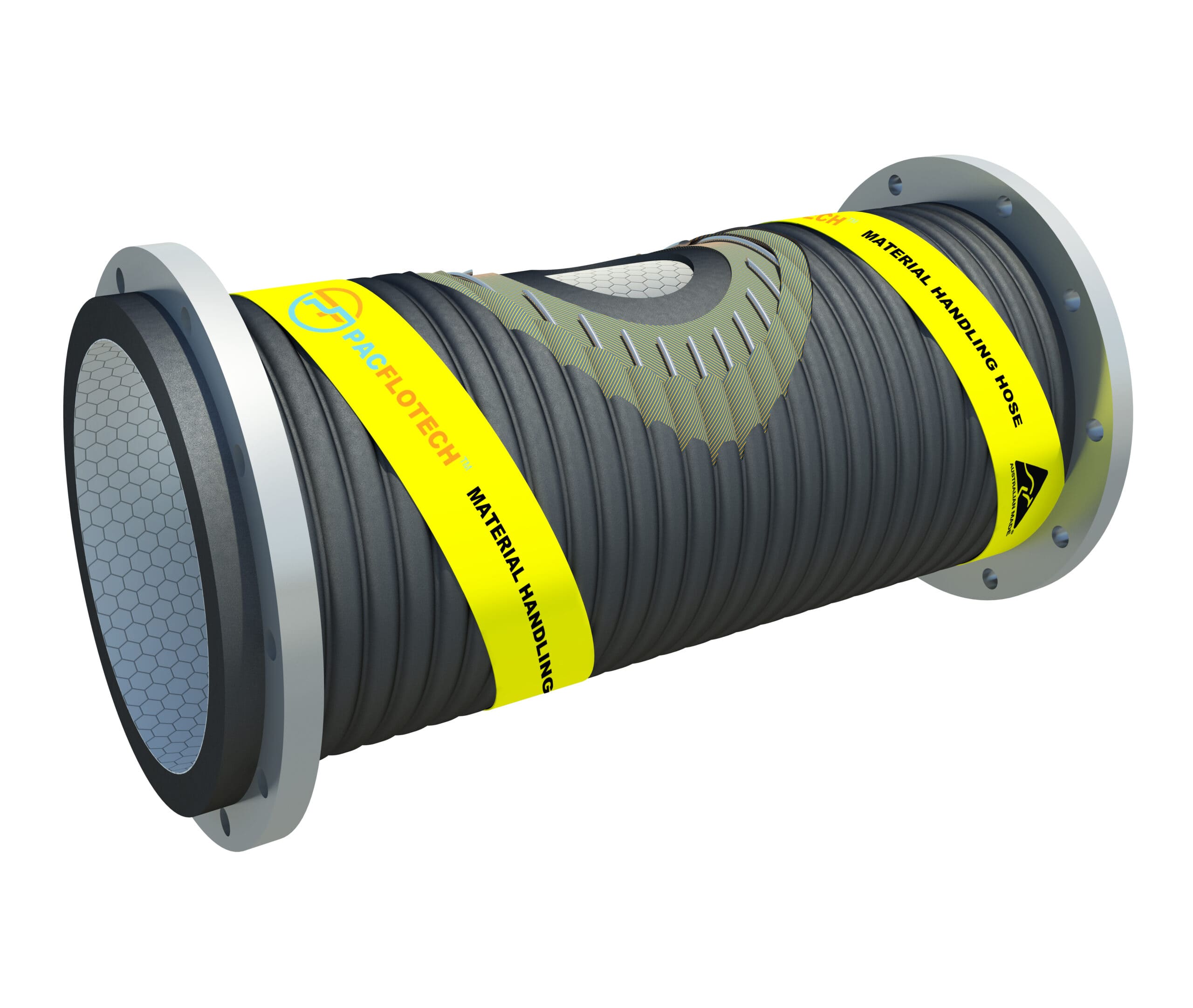

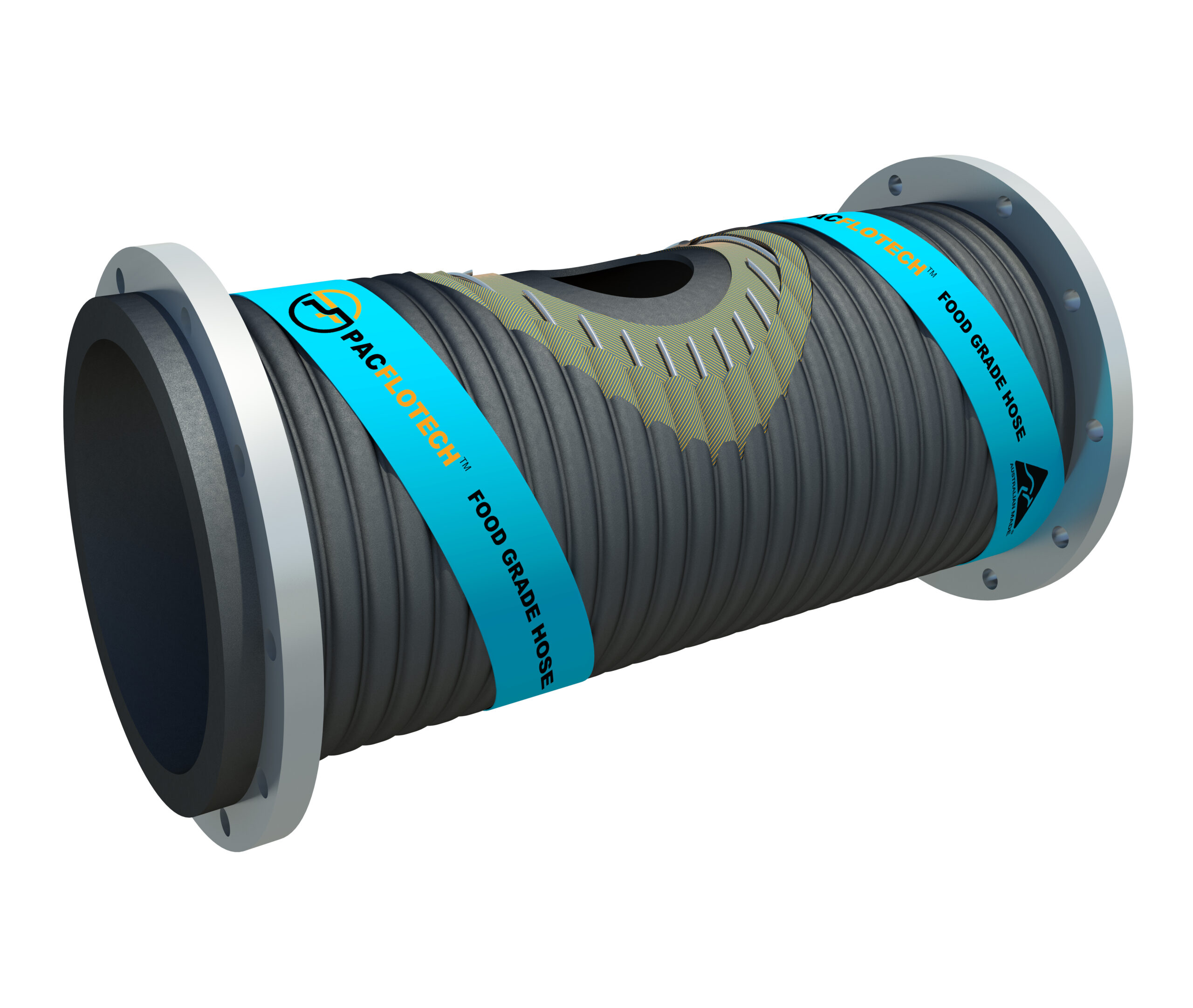

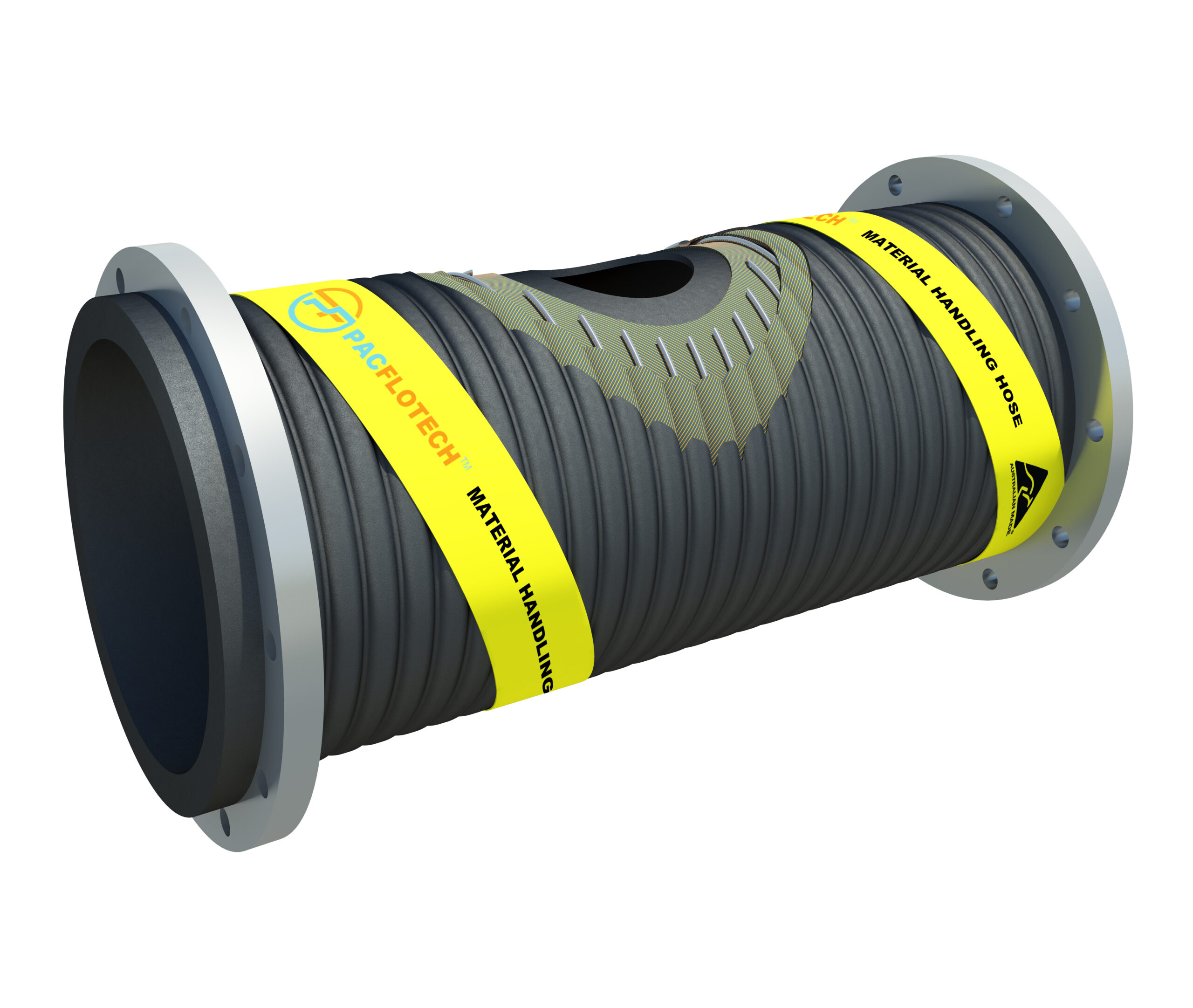

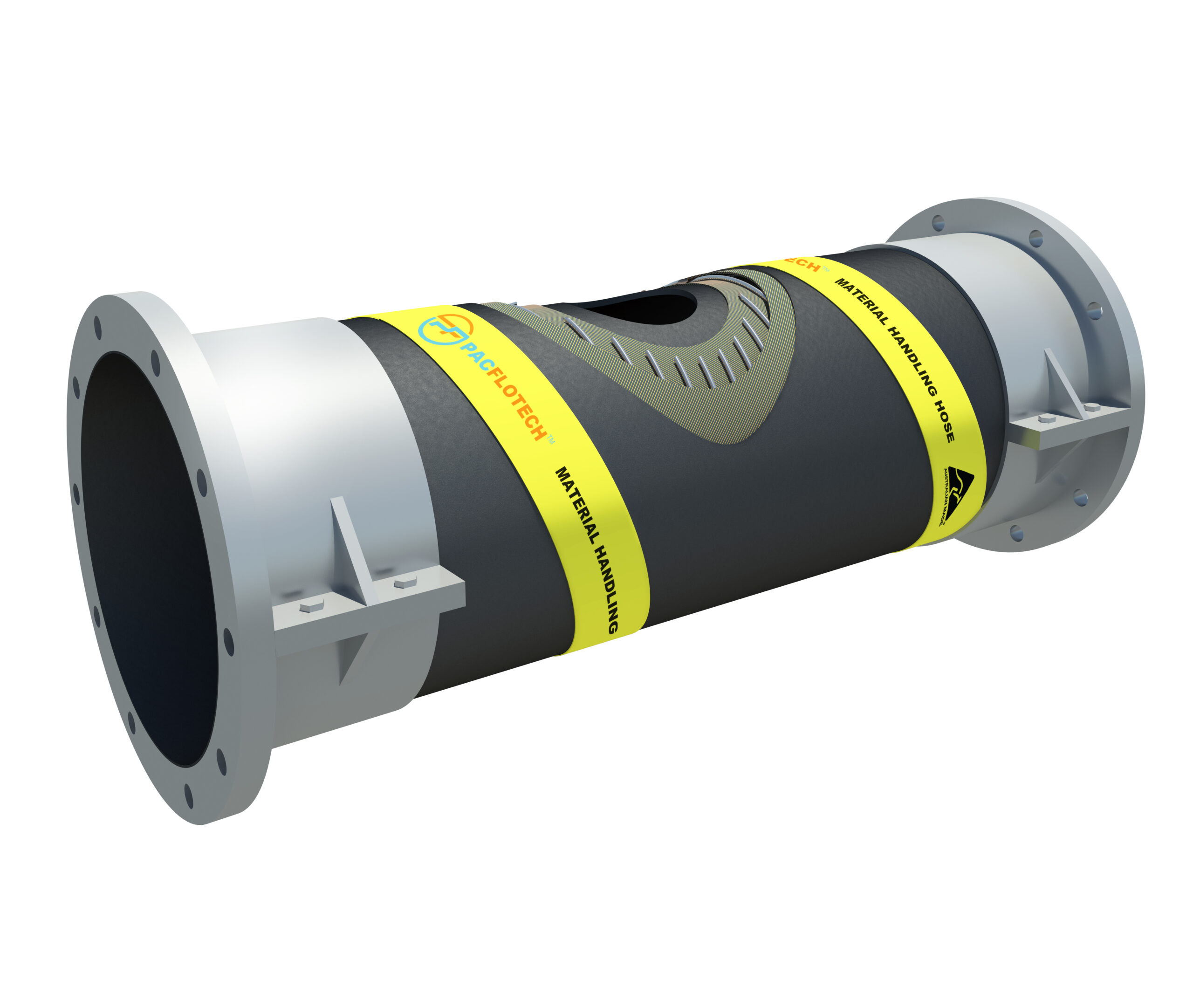

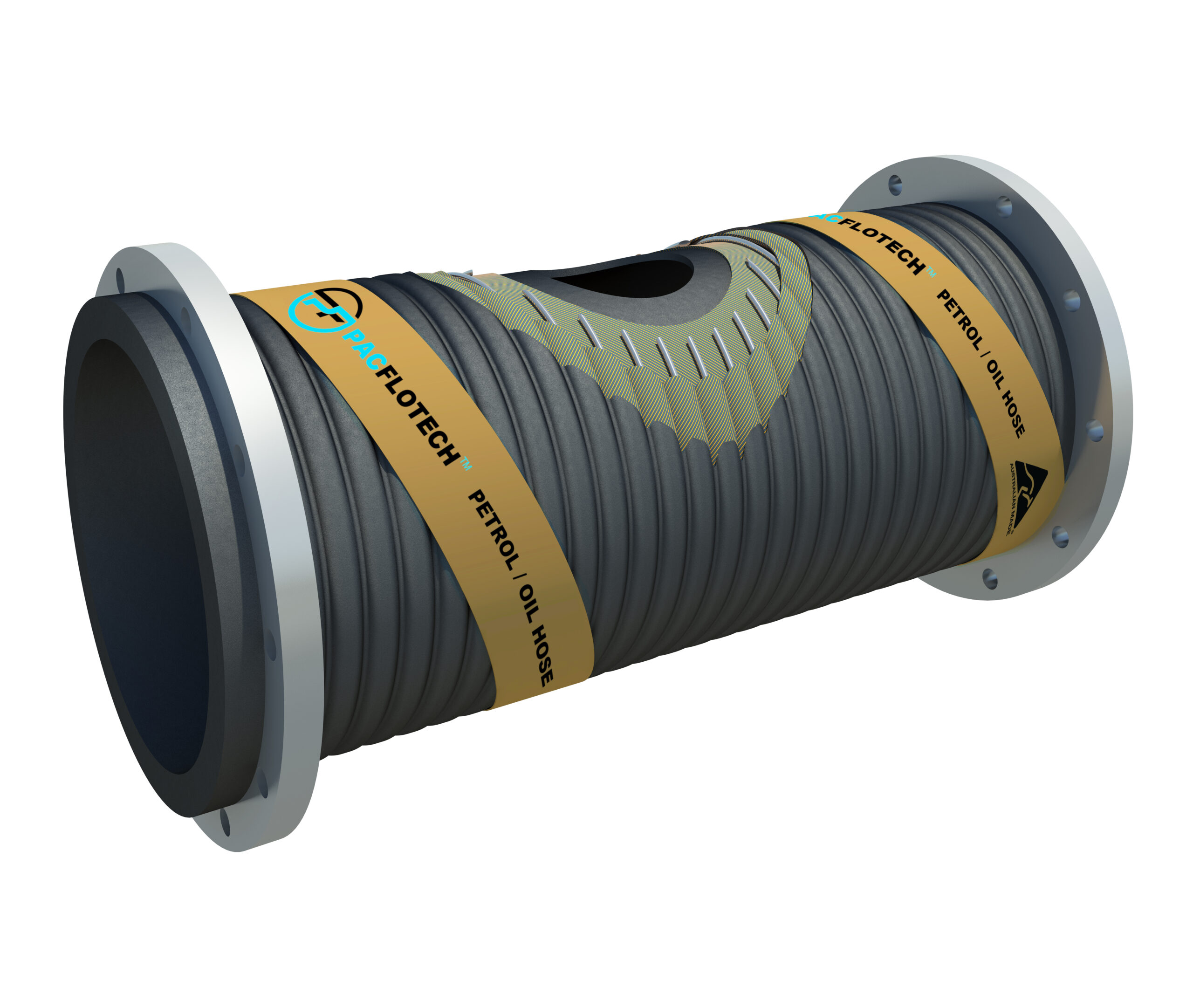

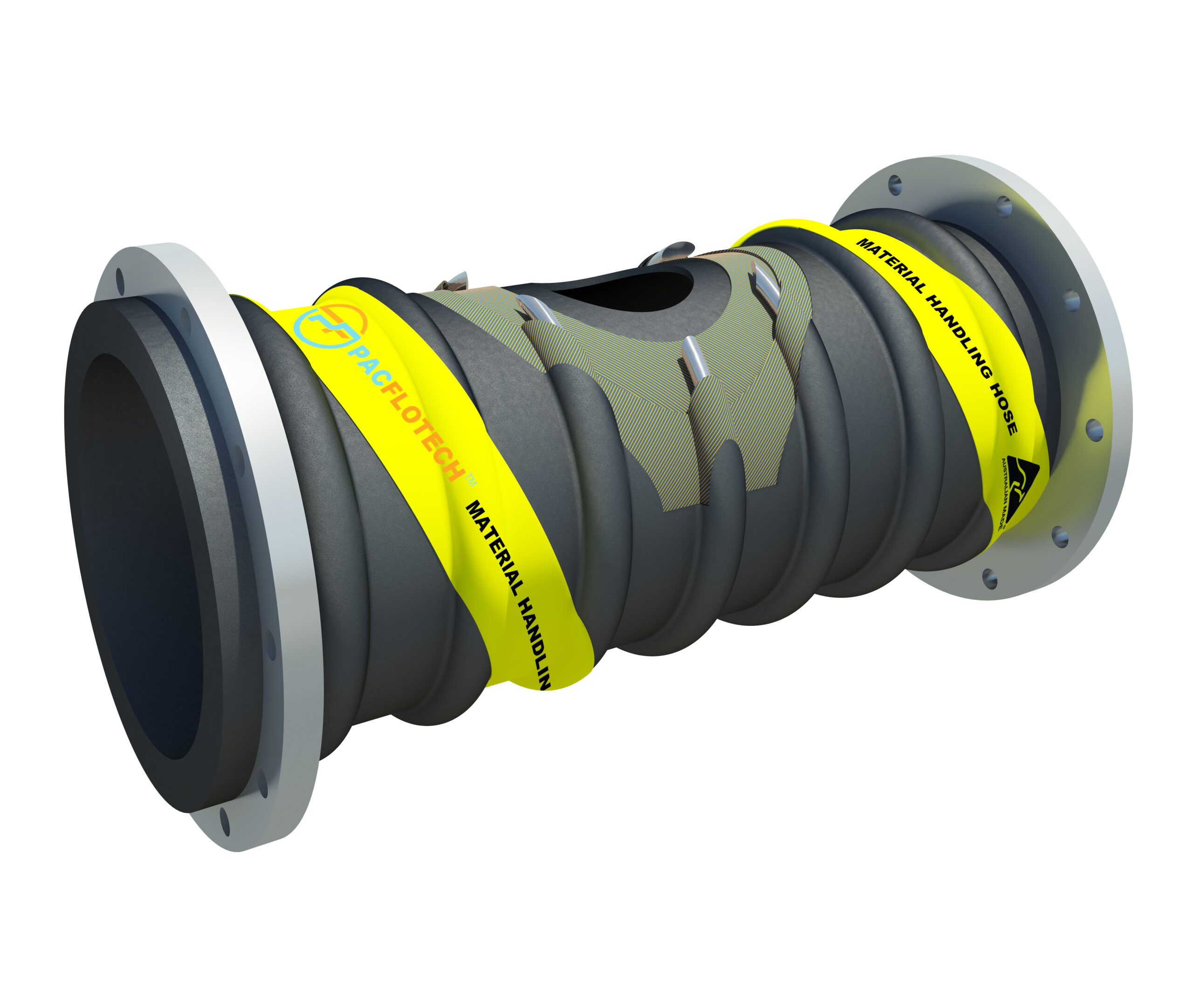

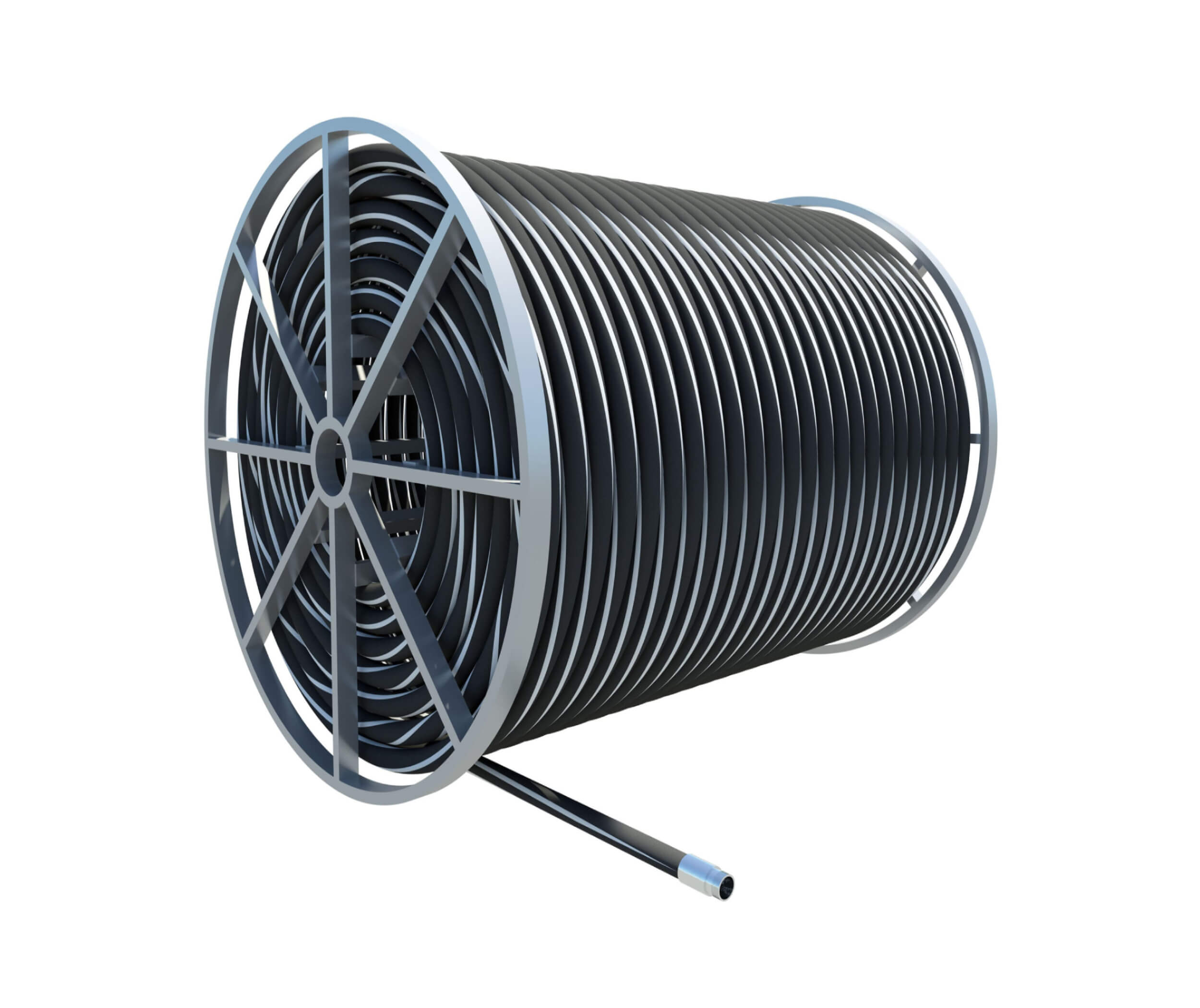

Dredge Hose

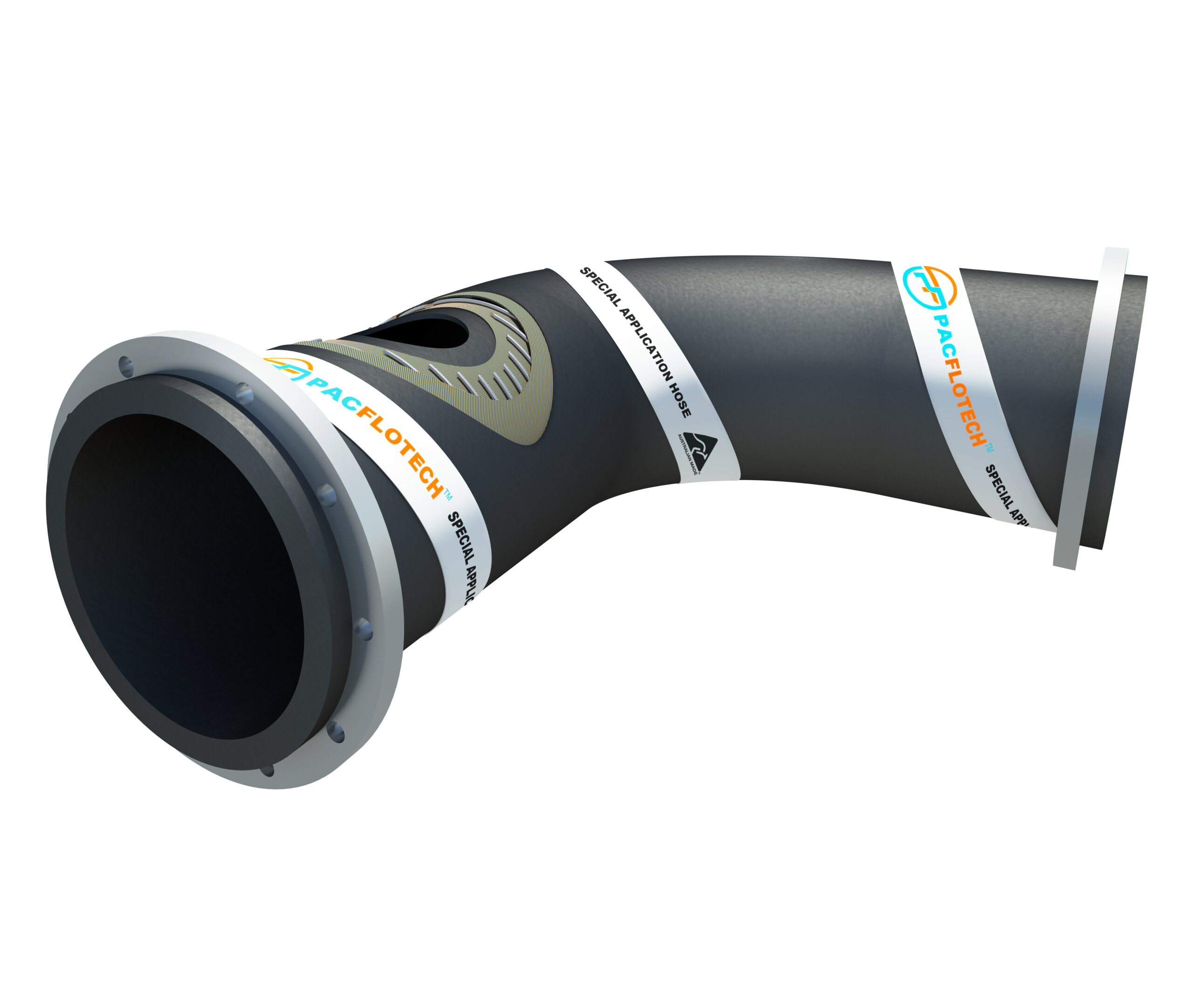

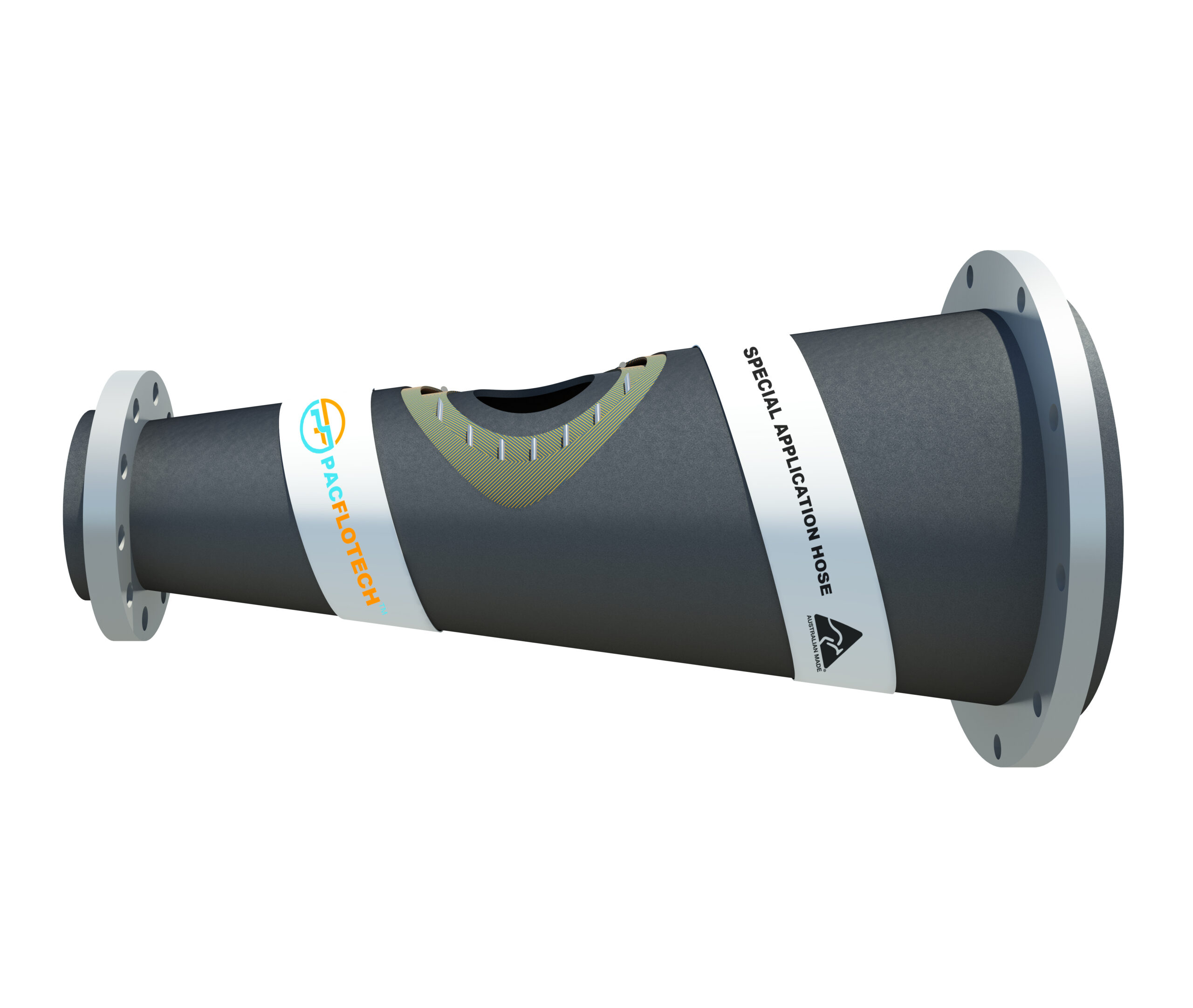

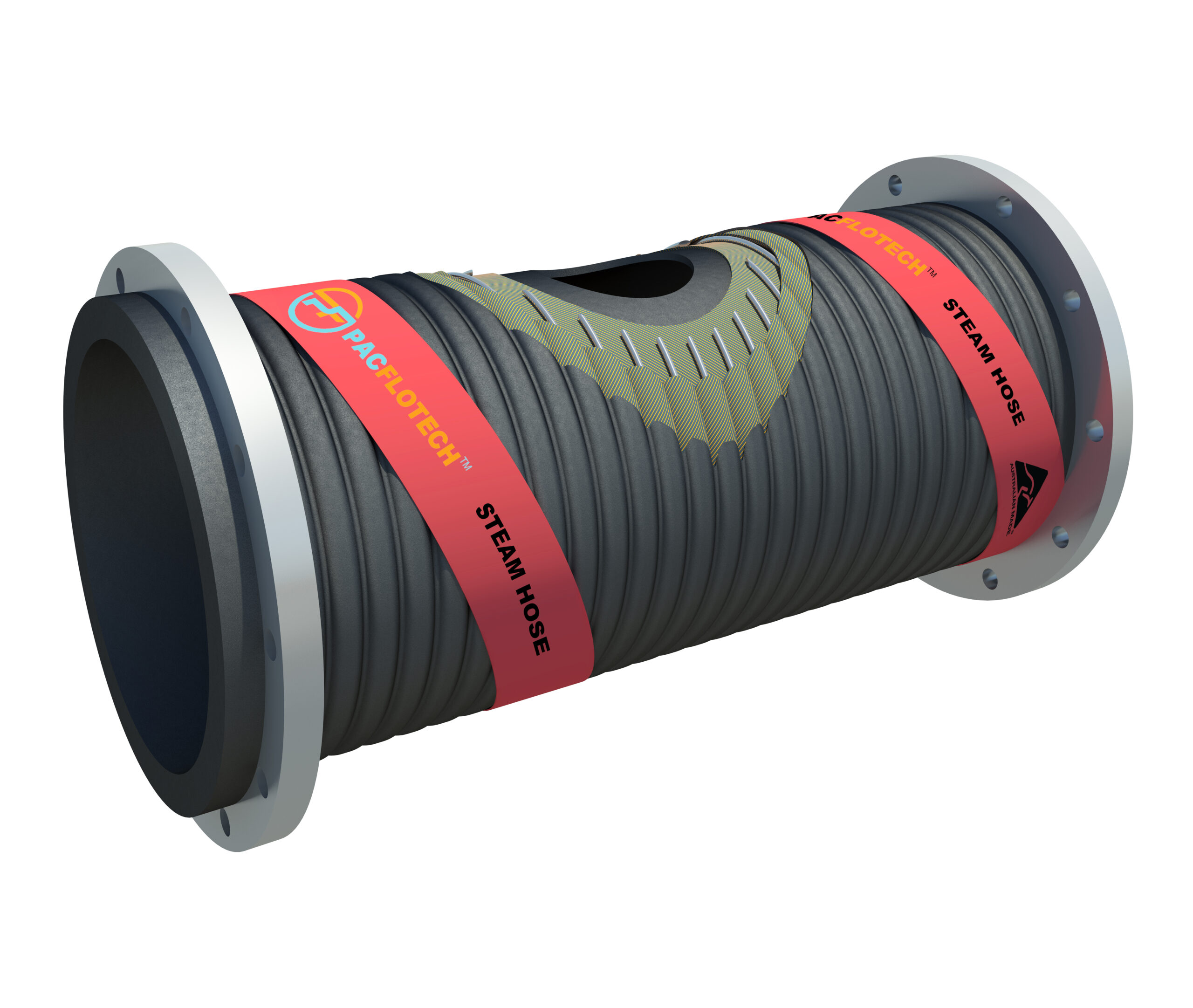

Pacific Flow Technology can provide a dredge hose in Australia made with thick steel hoops to prevent the hose from deforming under full vacuum, specifically designed to meet the most demanding dredging applications and deliver reliable performance in challenging environments.

In addition to preventing deforming, the thick steel hoops replace thinner spring steel wire, preventing kinking when under the arduous demands of suction dredging. The incorporation of Abrasatech liners also ensures maximum abrasion resistance to all kinds of slurry transferred through the hose. Whether you need a dredging rubber hose, dredging trunnion hose, ladder hose or dredge discharge hose for transferring sand, silt or other abrasive materials, we can provide what you need. We’ve earned a reputation for being one of the most trusted dredge hose suppliers and dredge hose manufacturers in Australia.

Expertise You Can Rely On

Backed by over 100 years of combined experience, Pacific Flow Technology specialises in crafting durable and reliable hoses designed to meet the demanding needs of the mining and dredging industries. With one of the largest handmade hose facilities in Australia, we’re equipped to design and manufacture hoses of any size or complexity, including dredge hose options for pivoting ladder assemblies. Our skilled hose builders ensure every product meets the highest industry standards.