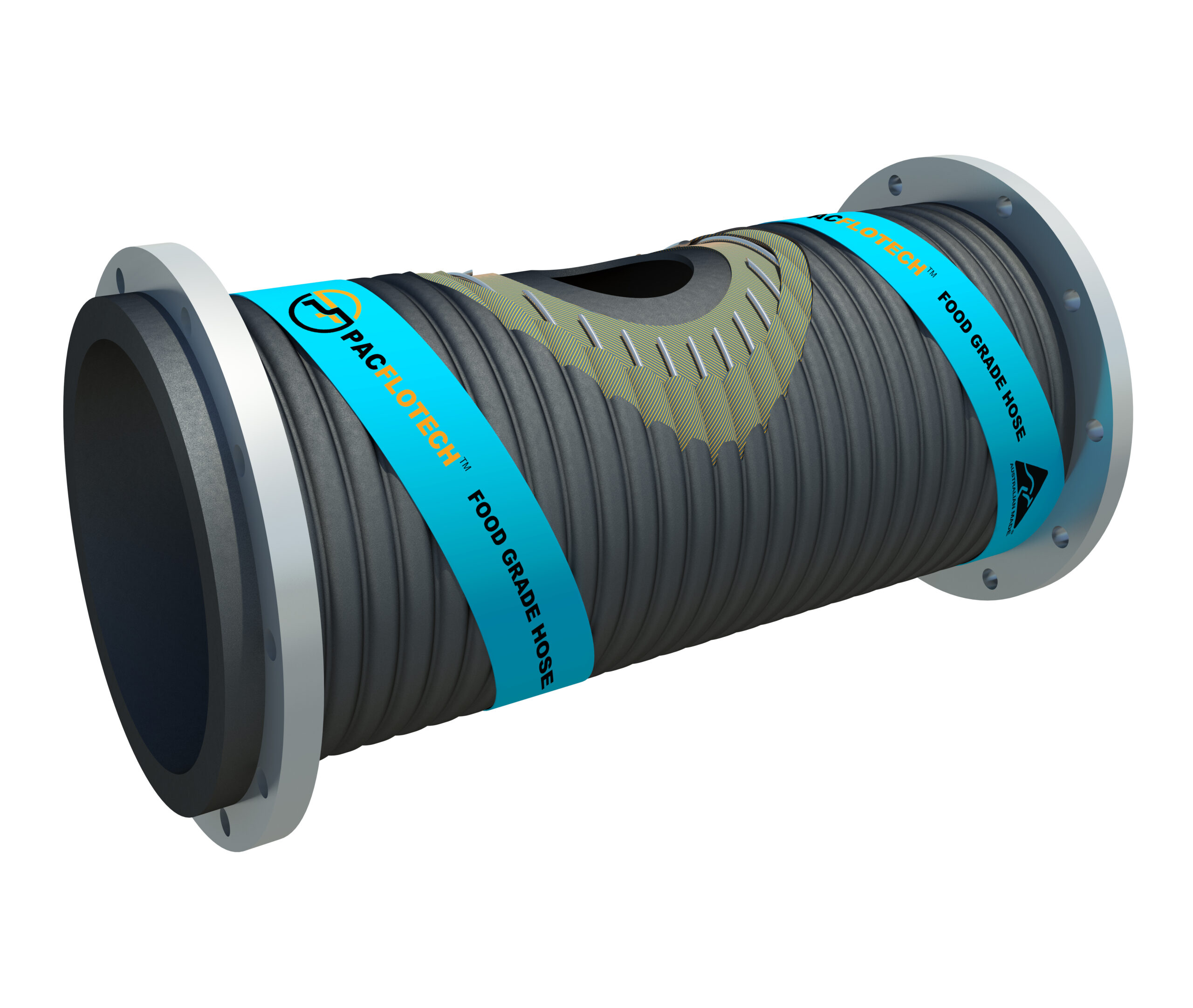

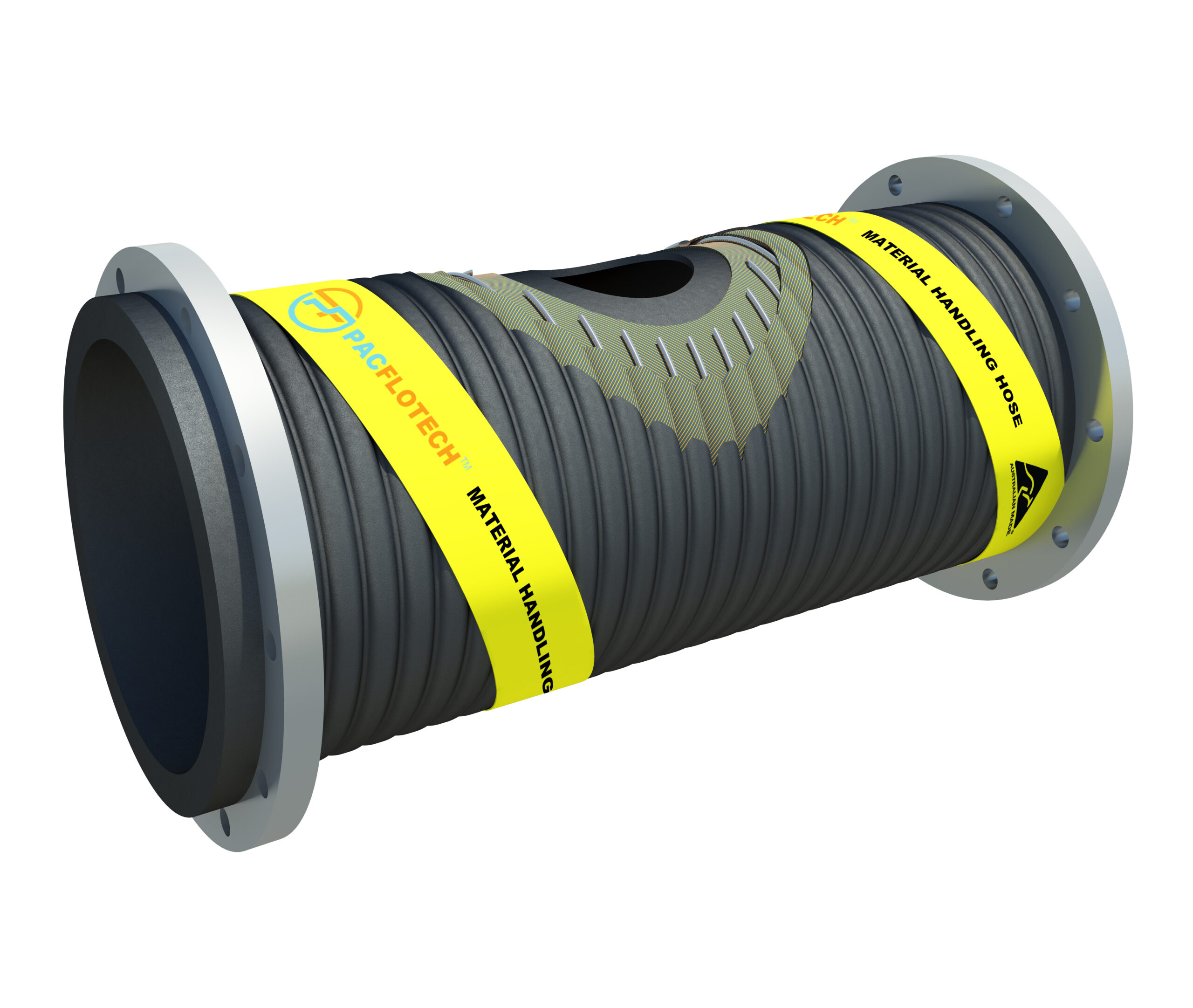

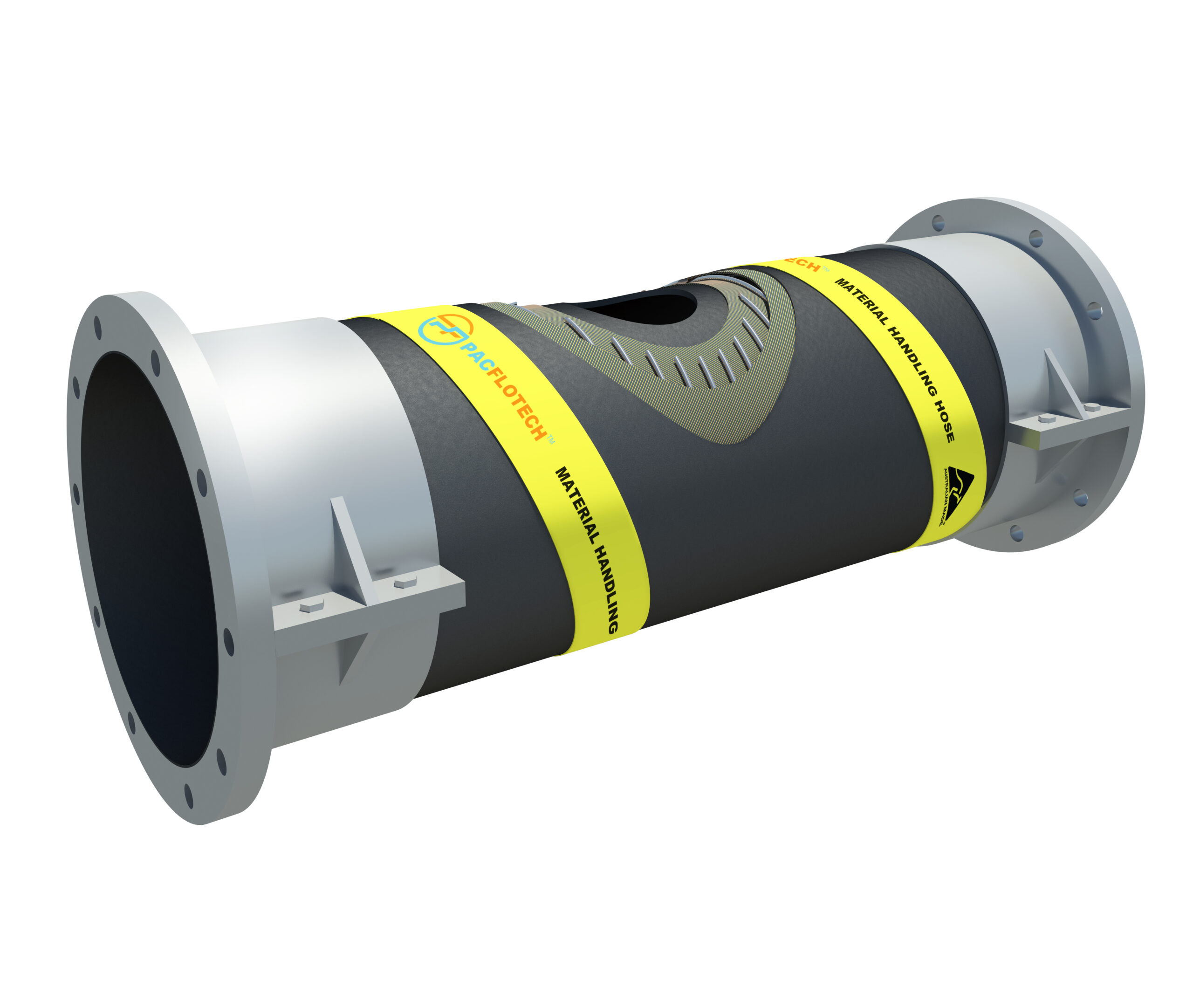

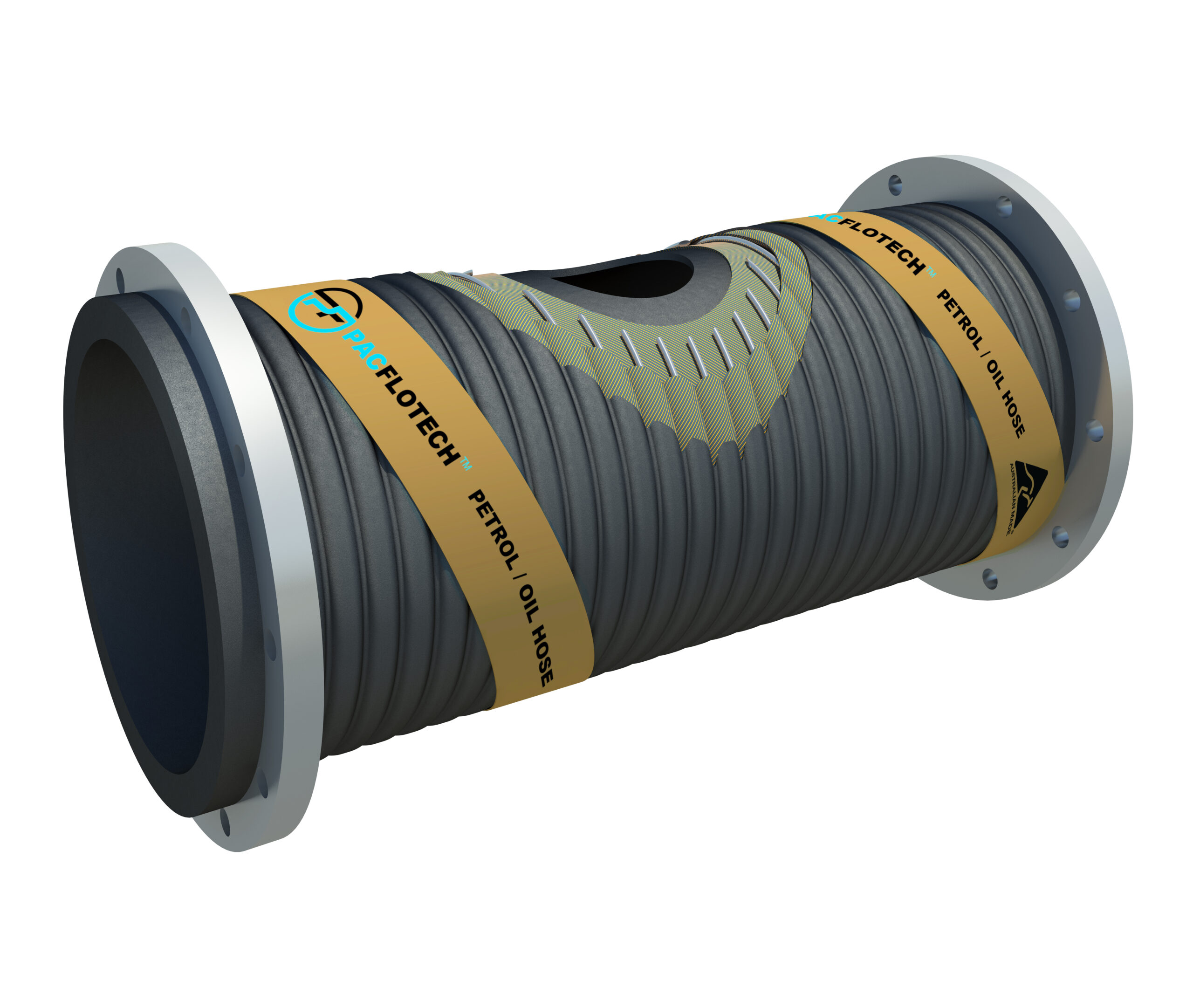

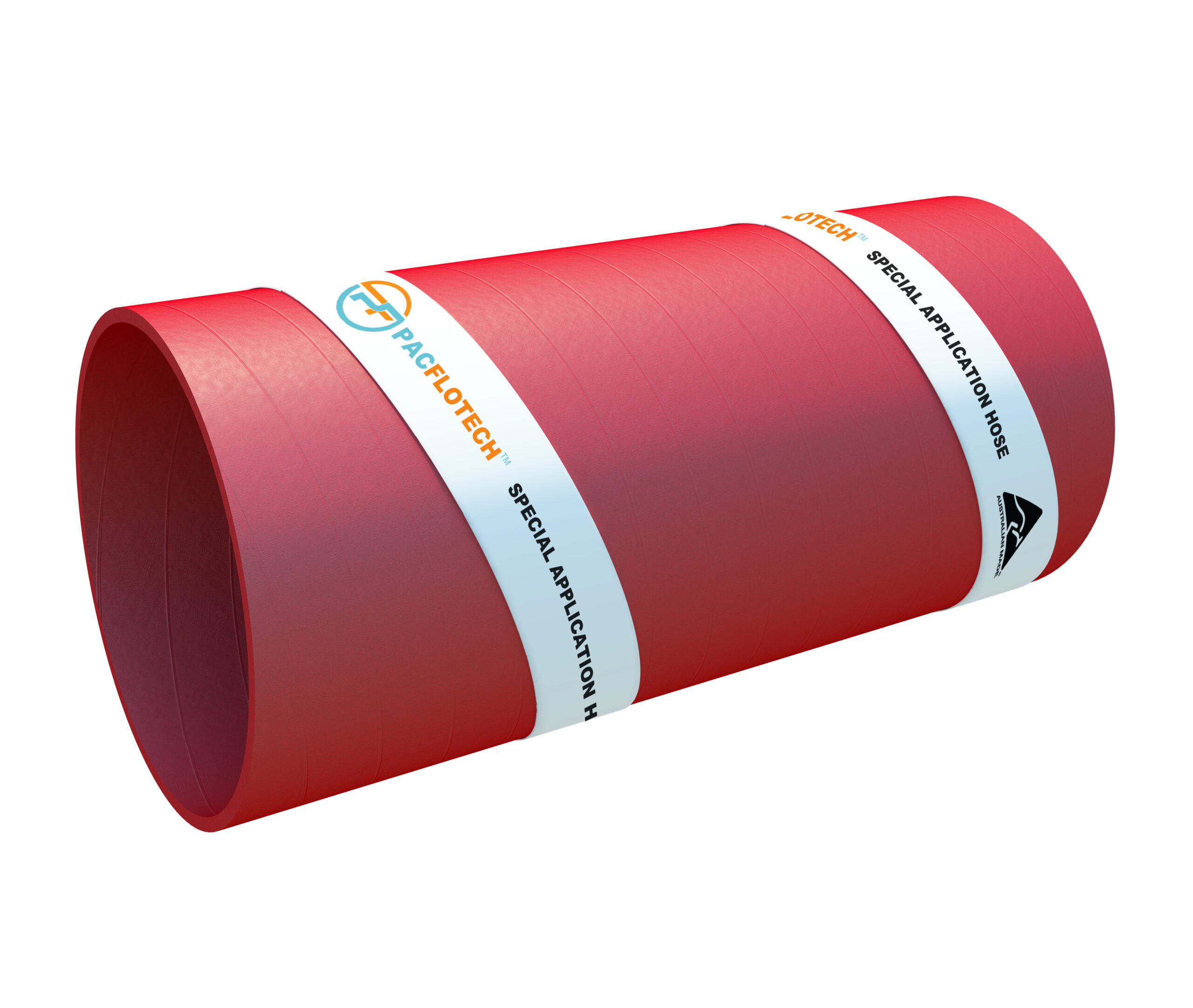

Food Grade Rubber Hose Food Grade Hose

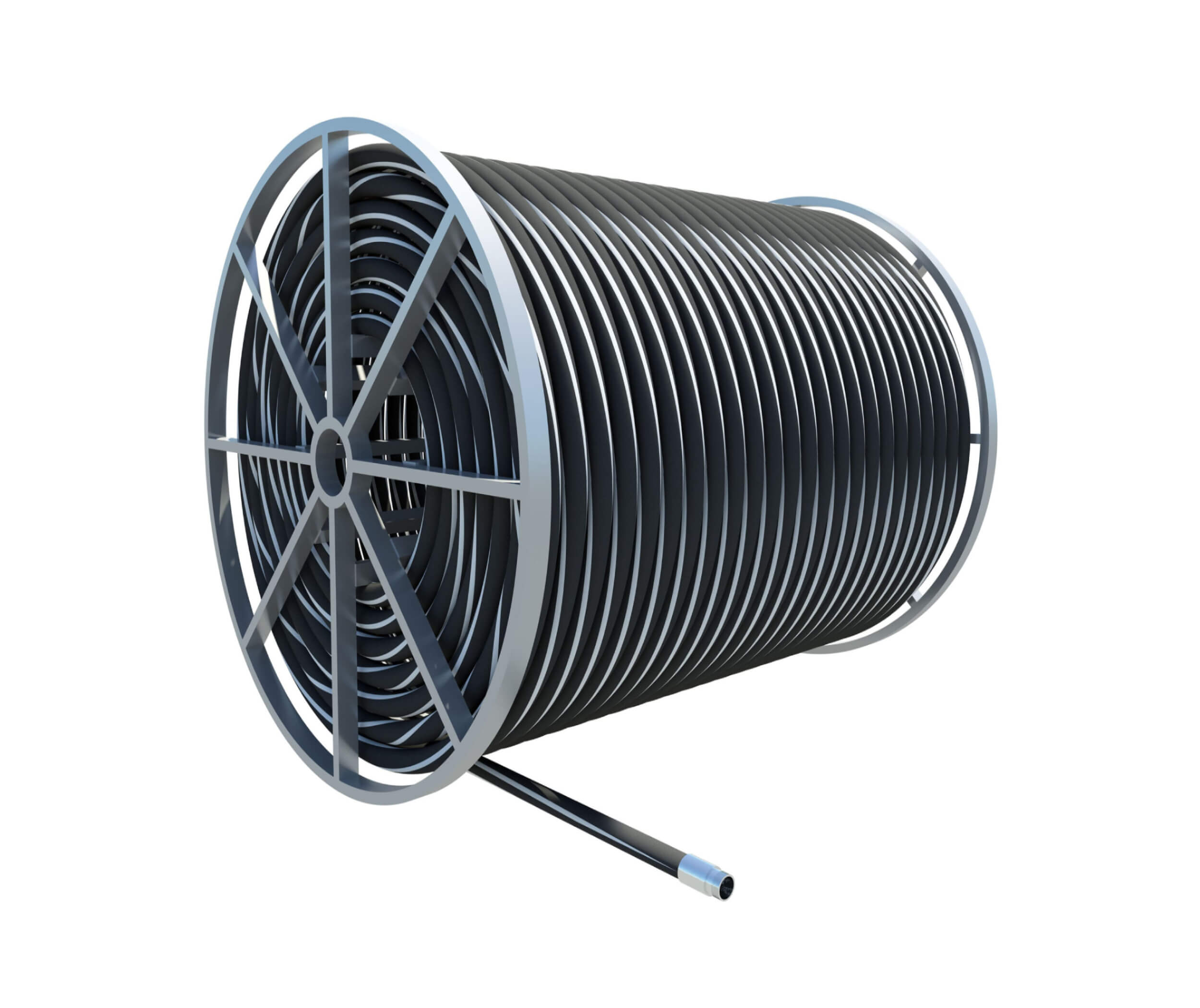

We offer reliable solutions suitable for transporting water, beverages and food. Our food grade rubber hose uses our FOODTECH™ AS4020 compound, an Australian standard-approved and FDA-compliant material made specially for potable water applications. This nitrile-based compound is formulated for enhanced resistance to oily and fatty substances, making it suitable for a wide variety of food and beverage applications. Delivering durability, flexibility and safety, our food grade hoses are designed to meet the stringent requirements of the food industry, ensuring high standards in both performance and hygiene.

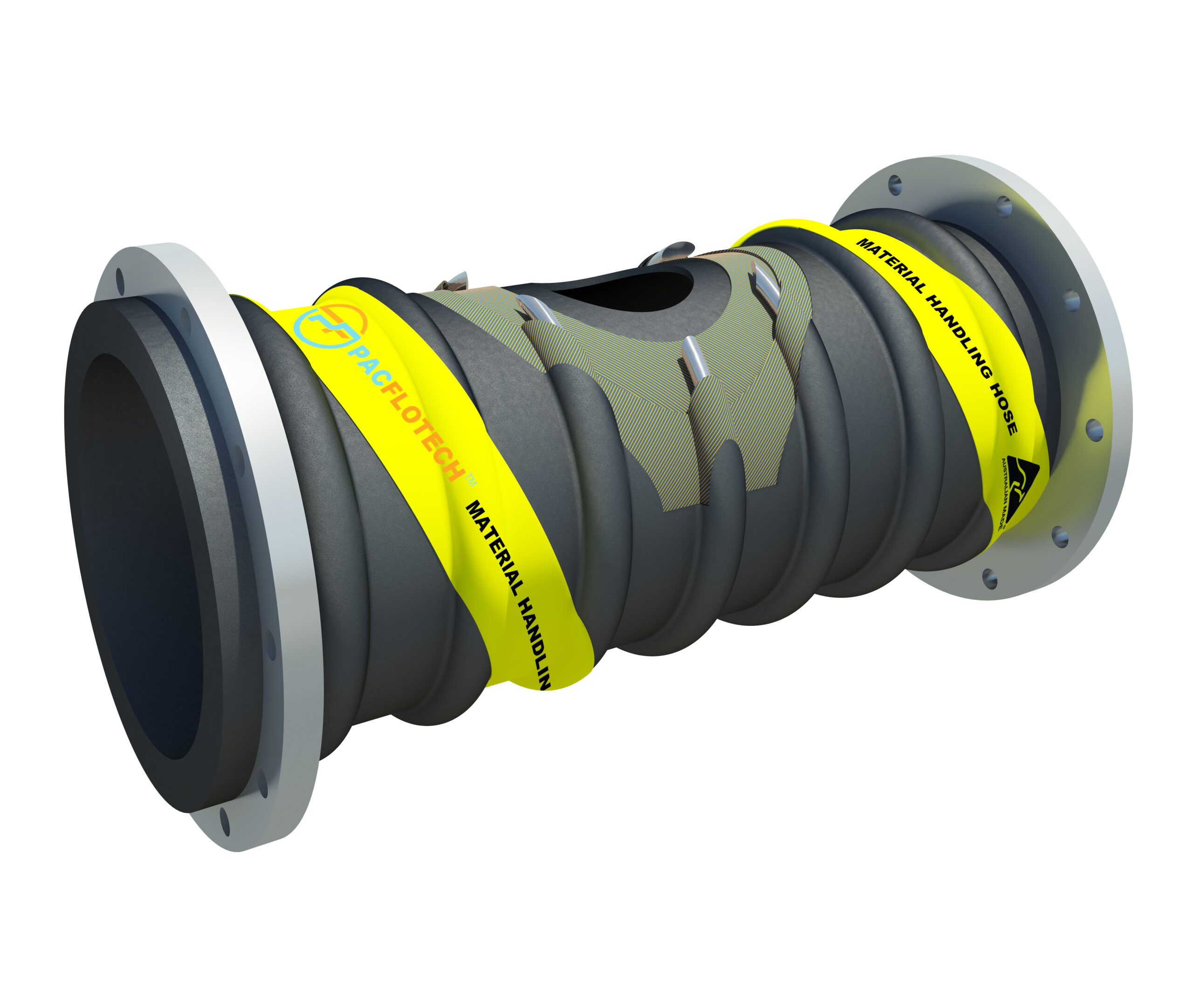

Tailored Solutions for Industrial Needs

Pacific Flow Technology’s expertise in rubber hose manufacturing is backed by over 100 years of combined industry experience, making us a trusted provider for the mining and food sectors. Whether you need a rig supply hose for mining or a specialised food grade rubber hose for beverages and consumables, you can trust that our products meet rigorous standards, ensuring the durability and safety our clients expect. We’re committed to supporting industries with dependable hoses that are tailored to specific requirements, delivering peak performance in demanding environments.