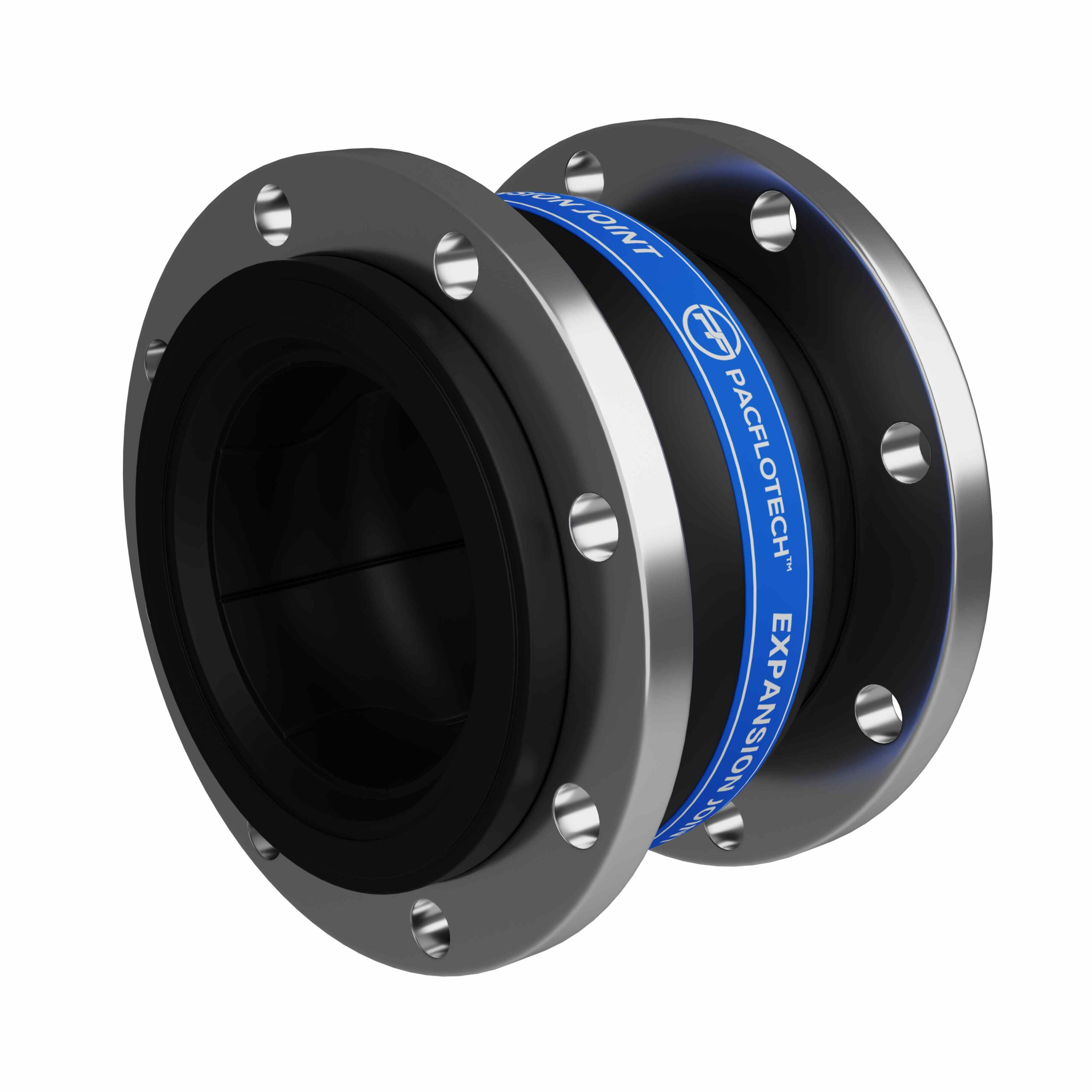

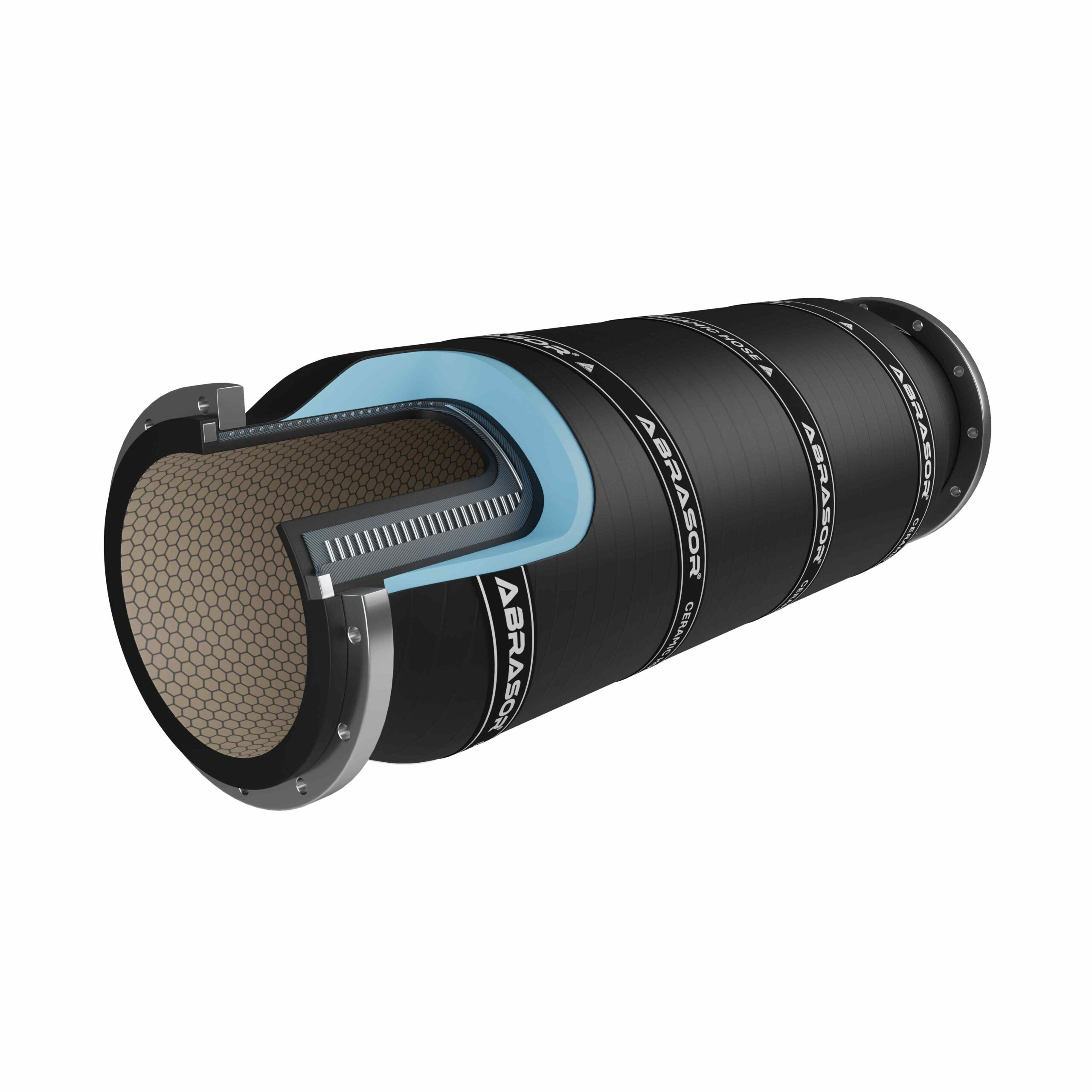

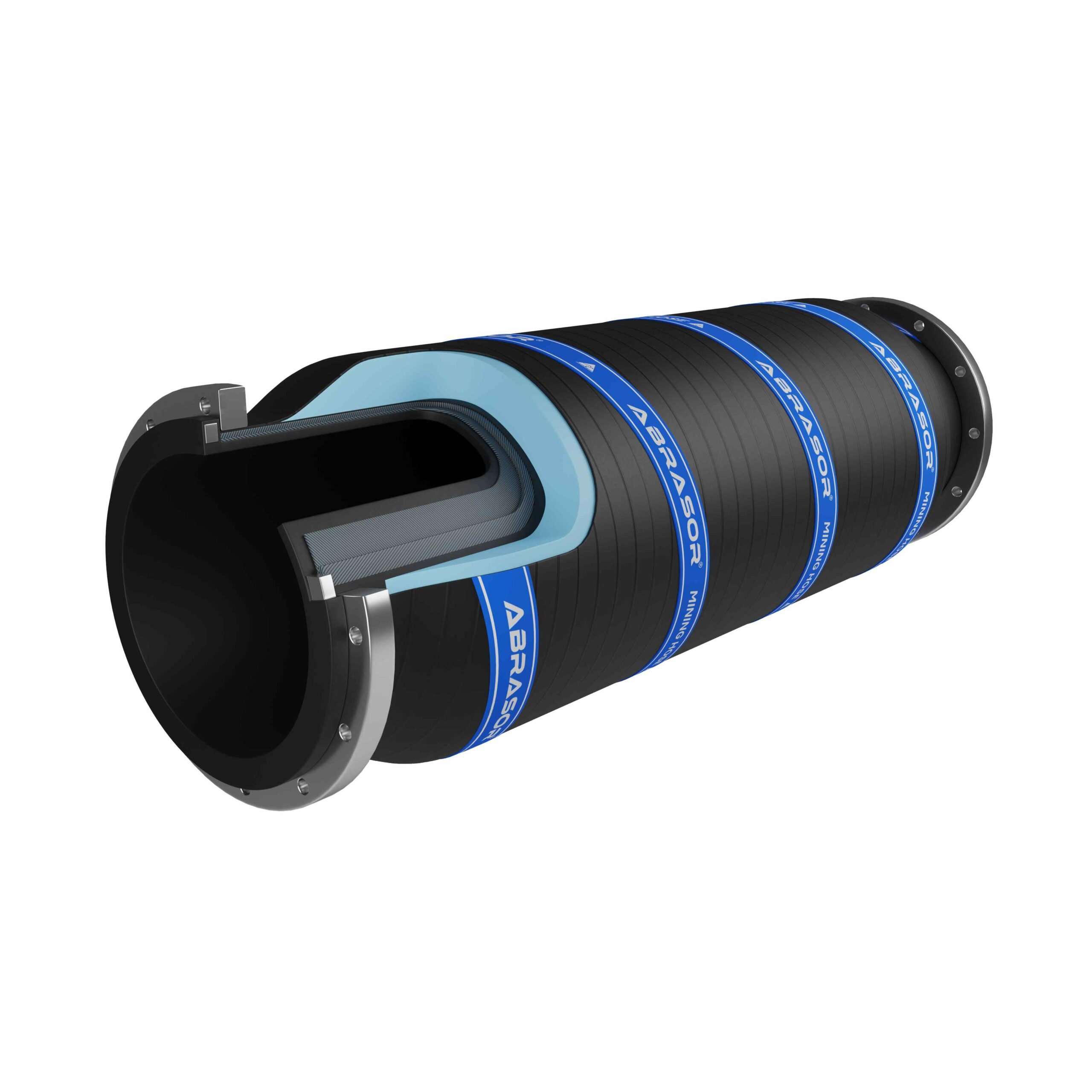

Abrasor® X80-Series Oil Resistant Rubber Hose is designed for superior performance in piping applications where hydrocarbon resistance is required. Can be offered in both hard wall and soft wall constructions, this hose series is built to suit a wide range of industrial uses, from petrol handling to oil-contaminated slurry transfer.

Proudly manufactured in Australia, Abrasor® is trusted by leading operators worldwide who demand performance, flexibility, and endurance from every metre of hose. We have the largest hand-made hose manufacturing facility in Australia, ensuring we have the capacity to meet your requirements no matter how big or small. We can offer a superior range of hydrocarbon resistant compounds, specifically designed for handling oily and petroleum-based mediums.